Most amateurs (15–30 handicap, driver <95 mph, or losing ≥2 balls/round) should start with Surlyn/ionomer cover for straighter flight, durability, and value; once you hit and hold greens, choose cast urethane for stop-and-drop control and higher greenside spin.

Are amateur golfers better off with Surlyn or urethane?

For most amateurs, begin with Surlyn/ionomer. Its side-spin reduction and higher durability keep off-center strikes straighter and cut consumables. Switch to urethane once you consistently land irons on the green and want tour-level short-game spin for tighter, more predictable stopping inside 50 yards.

-

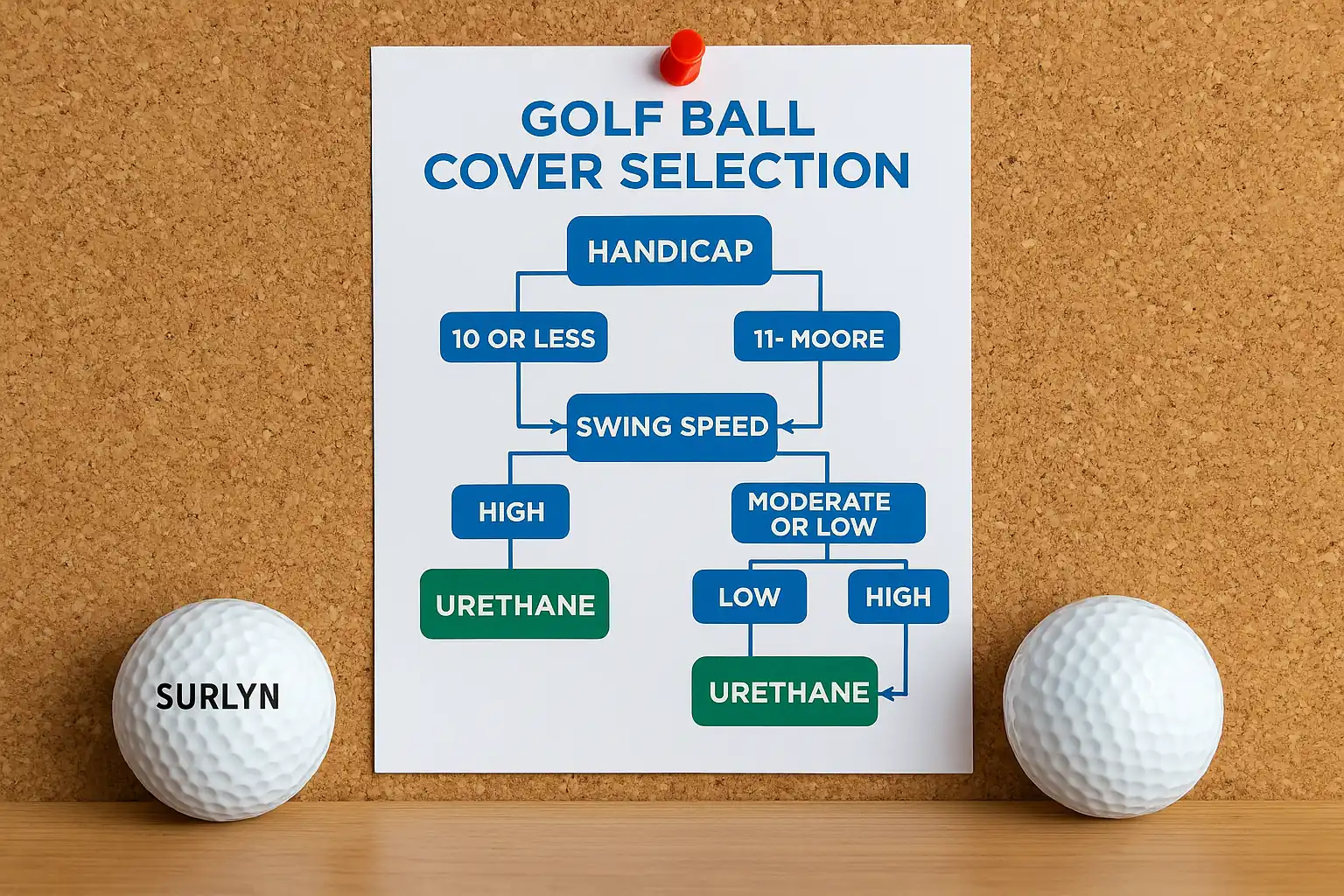

Quick decision matrix (swing speed/handicap/lost-ball rate)

Three signals: driver speed <95 mph, handicap ≥15, or losing ≥2 balls/round. Hit ≥2 ⇒ Surlyn. Hit ≤1 and practice your short game regularly ⇒ try urethane. In the gray band (HCP 12–18), test 3-piece urethane and see if greenside control improves.

-

When to upgrade from Surlyn to urethane (trigger points)

Pick two of three: (1) 9-iron/wedge regularly holds greens; (2) inside 50 yards you get too much rollout; (3) fast/firm greens push approaches past the target window. Then urethane’s value unlocks.

-

Budgeting with a fast “cost-per-round” estimate

Cost per round ≈ (ball price ÷ usable holes) + (lost-ball rate × replacement share). On unknown courses or with water/penalty risk, Surlyn lasts longer and needs fewer replacements. On scored rounds, urethane’s scoring return can justify the premium.

-

Problem→Section: Primary selection focus

Stabilize forgiveness and durability first; then invest where strokes move—short-game spin and consistency. -

Player routing table (recommendation)

Player condition (≥1) Recommended cover Why Alternate Driver <95 mph; HCP ≥15; lost ≥2 balls/round Surlyn/ionomer (2-piece) Lower side spin, tougher cover, lower unit cost 3-piece Surlyn or TPU HCP 10–20; greens matter more 3-piece cast urethane Higher approach/short-game spin, better stop-and-drop 2-piece Surlyn (unknown courses) HCP ≤10; ≥105 mph 3–4 piece cast urethane Full-bag control and tighter consistency 3-piece urethane (wind setups)

✔ True — Urethane’s edge is greenside and approach control

Inside 50 yards it produces higher spin and quicker deceleration for reliable stop-and-drop.

✘ False — “Urethane is always longer off the tee”

Driver gaps are usually small or player-dependent; face angle and strike quality dominate.

What exactly differs off the tee and around the green?

Off the tee, real-world gaps are small and vary by player; mishits amplify sidespin. Surlyn’s side-spin reduction tightens dispersion. Around the green is the divider: cast urethane yields higher spin, softer feel, and faster on-green deceleration, improving land-and-stop proximity.

-

Driver sidespin and dispersion

Surlyn: commonly lower side spin, moderating slices/hooks. Urethane: moderate spin, fine when delivery is solid, but more sensitive to strike quality.

-

50-yard spin/rollout and consistency

Urethane’s thinner, softer cover grips grooves better, giving shorter rollout and more consistent stopping. Surlyn tends to roll 1–3 m more, often the difference between a tap-in and a knee-knocker.

-

Green speed/hardness and material choice

Fast/firm greens magnify urethane benefits; slow/soft reduce the gap. If you mainly play muni/resort speeds, Surlyn is sufficient; for tournament-speed greens, urethane shines.

Course quick rules (≤30 words): Hard/fast → urethane; soft/slow → gap shrinks; wind/links → 3–4-piece urethane; hazards/water → Surlyn; sharp bunkers → Surlyn for cover life.

-

Problem→Section: Performance understanding and expectations

Nail start line and face control first. When you already hit and hold, chase higher greenside spin and stop-and-drop. -

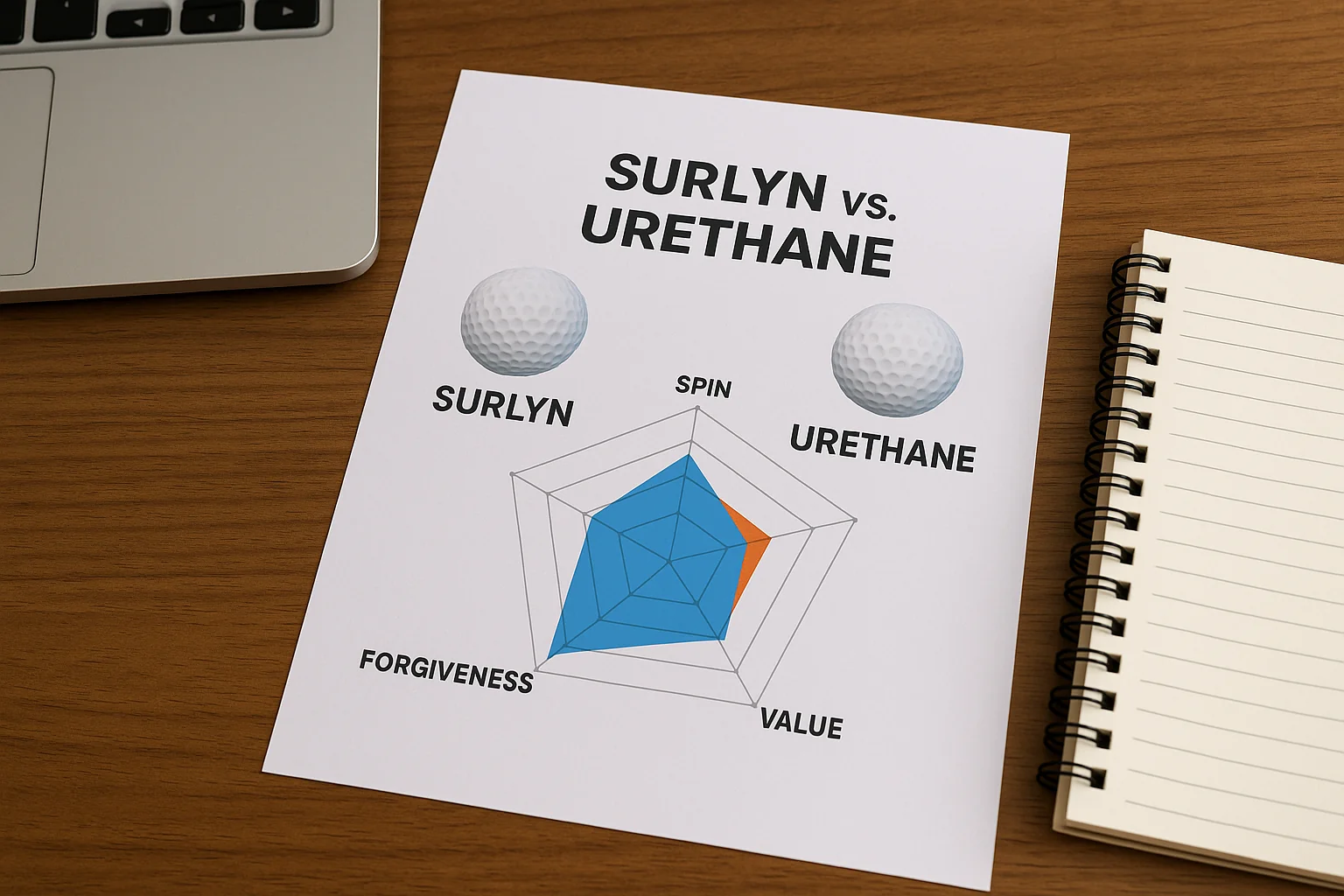

Driver/iron/short-game scorecard (ratings are illustrative)

Dimension Surlyn/ionomer Urethane Driver side-spin suppression ★★★★☆ ★★★☆☆ Iron distance stability ★★★★☆ ★★★★☆ <50-yard spin ★★☆☆☆ ★★★★★ Land-and-stop ability ★★☆☆☆ ★★★★★ Feel (soft/finesse) ★★☆☆☆ ★★★★★

✔ True — Feel/spin drive proximity, not raw distance

Soft feel aids touch and deceleration; driver distance depends on launch, spin, and compression fit.

✘ False — “Softer always goes farther”

Treat distance, compression, and spin as separate levers and fit each deliberately.

How should you balance durability, cost, and “consumable per round”?

Surlyn excels at scuff resistance and survives thin strikes/bunker shots with fewer cover burns—great for practice and high-loss rounds. Urethane scuffs sooner and costs more. Use cost per round = (price ÷ typical usable holes) + (lost-ball rate × replacement share). On unknown/wet/hazardous layouts, Surlyn is more economical.

-

Sand and sharp grooves: cover wear

Hard sand and sharp grooves raise fuzzing/scuffs on urethane; Surlyn’s ionomer cover resists chipping and keeps appearance longer.

-

Total cost of ownership (TCO) by play frequency

0–1 round/week or range-heavy: Surlyn value dominates. 1–2 rounds/week with scoring goals: 3-piece urethane pays back around the green. ≥2 rounds/week/tournaments: 3–4-piece urethane for consistency and wind stability.

-

Dual-ball strategy to keep feel continuity

Use Surlyn for practice/unknown courses; urethane for scored/fast-green days. Keep similar compression to reduce switching shock.

-

Problem→Section: Economics and lifespan

Compare cost per round against scoring return—not sticker price alone. -

Cover × typical usable holes × cost per round (illustrative)

Cover Typical usable holes (not lost) Street price (/dozen) Est. cost/round* Surlyn (2-piece) 36–72 $12–20 Low Urethane (3-piece) 18–36 $25–35 Medium Urethane (4-piece) 18–36 $40–55 Med–High Usable-holes range varies by bunkers, wedge groove sharpness, and course abrasiveness.

Example: $25/dozen, usable 36 holes, 1.5 lost/round → (25 ÷ 12 ÷ 36 ≈ $0.06/hole) + (1.5 × $2.08 ≈ $3.12) → ≈ $3.2/round.

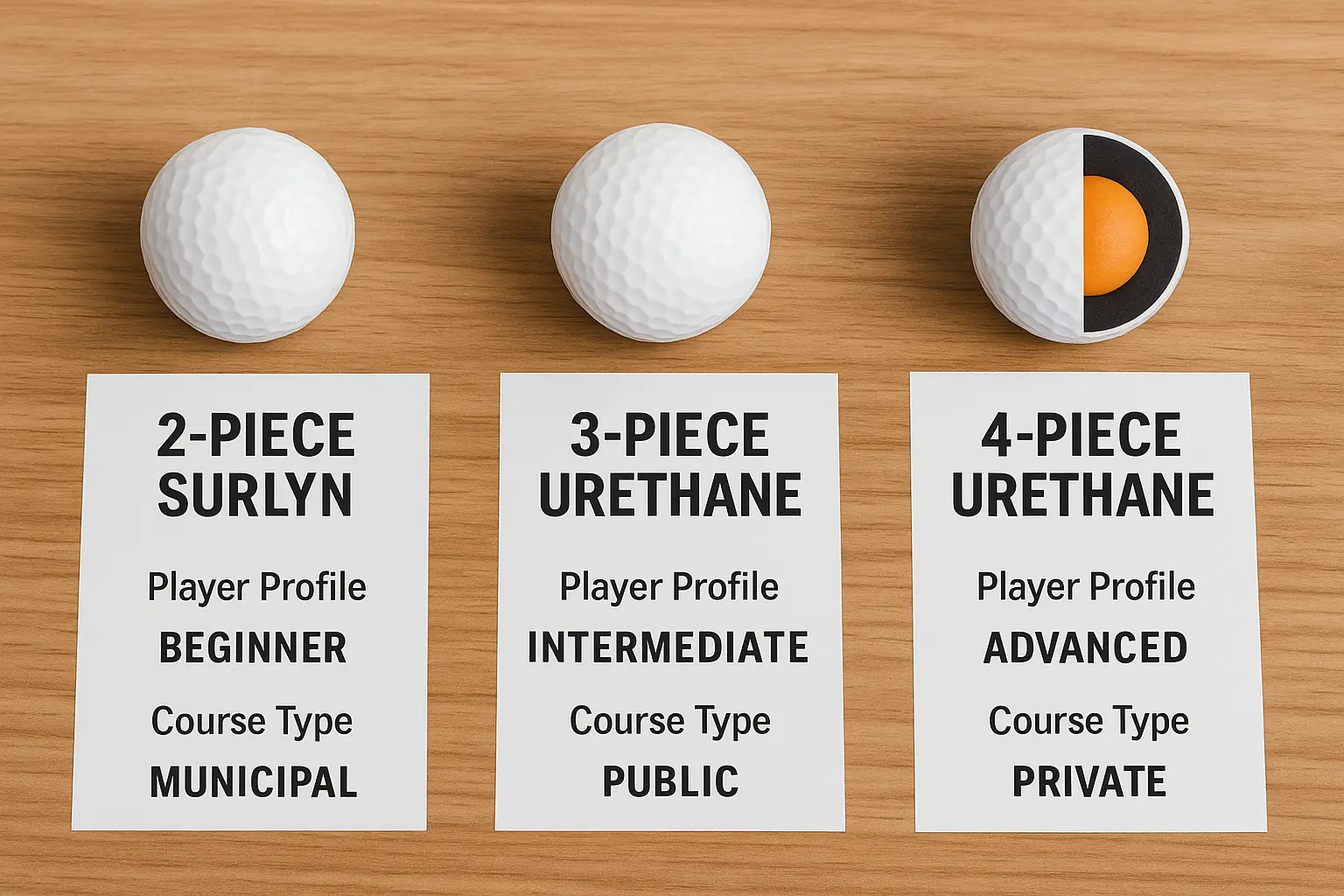

How should you combine construction (2/3/4-piece) with cover choice?

More layers ≠ more distance. High-volume entry is 2-piece + Surlyn for distance, forgiveness, and practice. Mid-tier is 3-piece + cast urethane for approach/greenside stopping. Premium is 3–4-piece + cast urethane for full-bag stability and tighter tolerances. TPU injection sits in the middle on performance and cost.

-

Who fits 2-piece Surlyn, 3-piece urethane, and 4-piece urethane

2-piece Surlyn: new golfers, HCP ≥20, higher loss. 3-piece urethane: HCP 10–20, regular practice. 4-piece urethane: HCP ≤10, ≥105 mph, competitive play.

-

Compression with feel/swing speed linkage

Lower compression helps low/mid speeds with launch/feel; higher speeds prefer mid–high compression. When changing covers, match compression to keep feel continuity.

-

Wind/fast greens/links: construction priorities

Wind/links: 3–4-piece urethane for flight stability. Fast greens: urethane advantage grows. Typical muni speeds: 2-piece Surlyn is adequate.

-

Problem→Section: Mapping construction to the player

Start with player and course; then pick layers. Consider TPU when splitting the difference on budget and spin. -

Layers × cover × speed/handicap × course (illustrative)

Layers × cover Speed/HCP Typical course Note 2-piece × Surlyn <95 mph / ≥20 Public/range; hazards Forgiveness/durability first 3-piece × Urethane 95–105 mph / 10–20 Club, slightly faster greens Approach stopping 4-piece × Urethane ≥105 mph / ≤10 Wind/links Full stability/consistency 3-piece × TPU 90–100 mph / 15–22 Mixed Balanced cost/performance

How do you run a 30–50 yard blind test to verify your material fit?

Same course & club; hit 5+5 balls. If average rollout gap is ≥2–3 m and scoring matters, adopt urethane; if not, stay with Surlyn to control spend.

-

Log template (model/landing/rollout/feel)

Fields: model, cover, layers, compression, landing-to-cup distance, rollout, total leave, subjective feel.

-

Green speed and wind: test interference

Run two sessions to dilute small-sample noise. When wind or slope changes, swap hitting order and landing windows.

-

Problem→Section: Self-proof to close the decision loop

Use data, not guesswork. Once the gap is clear, both confidence and buying efficiency improve. -

Blind-test worksheet (template)

Model Cover/Layers Compression 5 landings–cup (m) 5 rollouts (m) Avg. leave (m) Feel (1–5) A Surlyn/2 Low 4.1/3.8/4.2/3.9/4.0 3.2/2.9/3.1/3.3/3.0 6.9 3 B Surlyn/3 Mid … … … … C Urethane/3 Mid … … … … D Urethane/4 High … … … …

(B2B) How should channels and SKUs balance volume and brand image?

Run a dual-line architecture. Use 2-piece Surlyn for volume/practice and entry e-commerce; use 3/4-piece cast urethane for image/high ticket in club shops. Allocate inventory by region/season to avoid price-band cannibalization; use greenside demos to raise urethane mix and margin.

-

Surlyn:Urethane sales and margin goals

Ranges/Corporate: Surlyn drives volume and cashflow. Pro Shops/Gifting: Urethane lifts AOV and brand. Aim for a blend, not single-gear.

-

Peak-season scheduling, yield, and lead-time risks

Urethane, especially cast PU, has slower takt and needs tight cure/mold-temp control—secure capacity early. Surlyn injection offers faster cycles and chip-resistant seams, ideal for catch-up orders.

-

SKU differences by Pro Shop/e-commerce/range

Range/coach kits: 2-piece Surlyn (durability, low price). E-commerce mid: 3-piece urethane (HCP 10–20). Premium Pro Shop: 3–4-piece urethane with gift packaging.

-

Problem→Section: Category structure and margin

Use channel separation to prevent self-cannibalization; deploy fast-green demos where urethane converts best. -

SKU × layers × target × MSRP × margin band × MOQ × lead time (illustrative)

SKU Layers × cover Target user MSRP (/dozen) Retail margin (/dozen) MOQ Lead time (wks) S2 2-piece × Surlyn Entry/practice/group buys $12–20 $6.0–10.8 1,000–3,000 3–5 U3 3-piece × Urethane Mid cap/club play $25–35 $14.4–22.8 1,500–3,000 4–7 U4 4-piece × Urethane Events/gift sets $40–55 $21.6–31.2 2,000–5,000 6–9

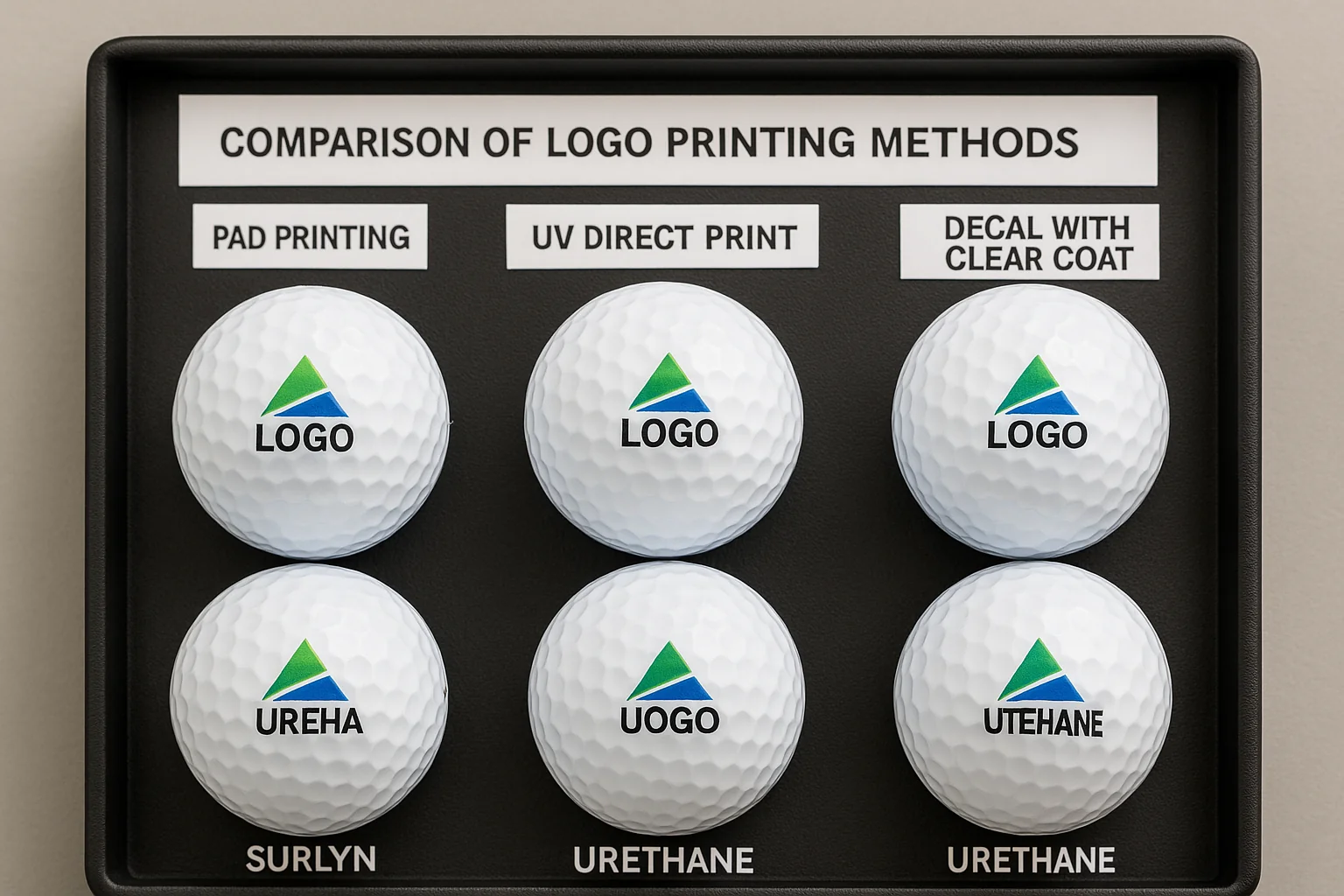

(B2B) Which logo customization process is faster and more reliable?

Pad printing for volume speed, UV direct for small multi-color rush, decal+clear for premium durability (slowest and most expensive). Urethane is solvent-sensitive; Surlyn needs surface activation or primer.

-

Pad print vs UV direct vs decal + clear coat

Pad print: stable, fast takt, low unit cost. UV direct: multi-color without plates, quick swaps. Decal + clear: best appearance/durability, longest lead/highest cost.

-

Trading off colors/durability/lead time/cost

1–3 colors: pad print. Large, multi-color graphics: UV direct with primer/flexible inks on urethane. Flagship gifts: decal embedded under clear for top scuff/yellowing resistance.

-

Common failures and process controls

Urethane solvent sensitivity → choose 2K epoxy/PU inks and control thinners. Surlyn low surface energy → mandatory plasma/corona/flame or primer. Screen printing suits only simple single-color, flatter spots.

-

Problem→Section: Delivery efficiency and quality

Choose by art complexity × volume × deadline; front-load risks in sampling to avoid mass rework. -

Process × color count × cost × lead time × cover (illustrative)

Process Colors Cost Lead time Cover Pad print (solvent/UV) 1–3 Low Fast Surlyn/Urethane UV direct (white+CMYK) Multi/gradients Medium Fast Surlyn / (Urethane needs primer/flexible inks) Water decal + clear (co-cure) Multi/high detail High Slow Urethane-preferred (premium) -

China-based OEM options for Surlyn & urethane golf balls (for sourcing reference)

Factory City Capabilities MOQ Ningbo Golfara Ningbo 2-piece Surlyn; 3/4-piece urethane 1,000 pcs Xiamen MLG Sports Xiamen Surlyn & urethane; 2/3/4-piece 1,500–2,000 pcs Shenzhen Xinjintian Shenzhen Surlyn & urethane; includes 4-piece 3,000–10,000 pcs Shenzhen Crestgolf Shenzhen Surlyn; custom 3-piece urethane 2,000–3,000 pcs Shenzhen Zetu Sports Shenzhen Surlyn & urethane; 2–4- piece 2,000–3,000 pcs -

Note: MOQs are typical bands and may vary with logo process (pad/UV/decal), packaging, and peak-season capacity.

FAQ

Will low swing speed (≤90 mph) lose distance with urethane?

Usually not by much—and not guaranteed to be longer either. Driver distance depends most on impact quality, launch, spin, and compression fit, not cover alone. If short-game spin matters more, try 3-piece urethane; if you lose balls often, start with Surlyn.

Match compression to minimize feel shock. If your blind test shows ≥2 m less rollout with urethane, the scoring ROI usually outweighs small tee-box differences.

I lose 2–3 balls per round—which cover saves money?

Choose Surlyn. It’s more scuff-resistant and cheaper per unit, so cost per round is easier to control. On unfamiliar or hazard-heavy courses, Surlyn reduces replacement frequency and appearance-driven discard.

When you know the course and lose fewer balls, deploy urethane for scored rounds or faster greens. A dual-ball strategy balances budget and scoring.

Can Surlyn stop on hard/fast greens?

Yes, but placement and height matter more. On fast/firm greens, Surlyn typically rolls farther, so pick a more forward landing spot and increase descent angle. If you already attack pins and value hold, urethane makes it easier.

On slower/softer greens the gap shrinks. For fast-green events, a temporary urethane switch is a smart adjustment.

Is TPU a Surlyn or urethane type? How far is it from urethane?

TPU is a middle path. As thermoplastic polyurethane, it offers injection efficiency, feel/spin between Surlyn and urethane, and mid-range cost.

If both budget and short-game needs live in the middle, TPU provides softer touch than Surlyn with better durability than cast urethane. For maximum greenside spin and flagship consistency, cast urethane still leads.

Will practicing with Surlyn and competing with urethane hurt feel stability?

Impact can be managed. Keep similar compression/feel bands and schedule 10–15 minutes of short-game acclimation before rounds when switching. Most players adapt within one or two cycles.

Blend blind-test results with cost per round. If urethane gives clearly shorter rollout and repeatable stopping, switching on “score days” is meaningful; otherwise, staying all-Surlyn is fine.

On sandy courses or sharp-groove wedges, which cover is tougher?

Surlyn lasts longer. Ionomer covers are more abrasion- and chip-resistant; urethane is more prone to fuzzing/scuffs after hard-sand escapes.

If you play such conditions often, reserve urethane for scored rounds and use Surlyn otherwise. For urethane, consider groove maintenance and more frequent rotation.

For mid handicaps (10–20), 3-piece urethane or 2-piece Surlyn?

It depends on short game and ball loss. If you hold greens regularly and care about grab-and-stop, 3-piece urethane fits. If you lose ≥2 balls/round or play unknown courses often, 2-piece Surlyn protects budget.

In the gray area, try 3-piece urethane and run the 50-yard blind test. If proximity improves materially, keep urethane for score days.

Do multi-color/large logos peel easier on urethane?

More sensitive but controllable. Urethane needs 2K epoxy/PU inks and full cure; for multi-color/large areas, use UV direct with primer/flexible inks or water-decal + clear co-cure for top durability.

Surlyn’s low surface energy requires plasma/corona/flame or primer. For gift-level look and anti-yellowing, decal + clear is best—slower and costlier.

Conclusion

Use simple rules: if you’re 15–30 handicap, <95 mph, or lose ≥2 balls/round, start with Surlyn/ionomer for straighter flight, longer life, and better value. Once you hit and hold greens and want higher spin and stop-and-drop inside 50 yards, upgrade to cast urethane. Need sample kits or the blind-test worksheet? Reach out anytime.

You might also like — How to Buy Golf Balls Directly from a Chinese Manufacturer?