China manufactures practice, Surlyn, and private-label custom logo golf balls at scale, with select plants producing limited multi-layer urethane (“quasi-Tour”) models. Quality for two-/three-piece Surlyn is mature; urethane performance depends on materials and process control.

What is the current state of golf ball manufacturing in China?

China produces practice balls, entry-to-mid two-/three-piece Surlyn/TPU, private-label logo and gift lines, plus limited three-/four-piece urethane “quasi-Tour.” Annual exports are ~280–290 million pieces with value in the low-hundreds of millions USD (latest full year, e.g., 2023), led by the US and Korea, followed by Japan and the UK.

China’s portfolio spans PU foam/sponge trainers, durable RANGE balls, two-/three-piece Surlyn/TPU performance balls, and private-label promo packs with integrated packaging. For multi-layer urethane, capability exists but mass-production consistency varies by resin system, bonding windows, and process control. Export flows to the US and Korea are strong, with steady business to Japan and the UK. Industrial clusters in Guangdong, Fujian, and Zhejiang split by strengths—automated volume, flexible MOQs, and packaging/printing depth—so buyers can match common specs quickly and compress FOB China timelines through integrated molding-to-carton operations.

What types of golf balls can Chinese factories produce?

Factories routinely make two-/three-piece Surlyn/TPU models, RANGE balls engineered for durability, and PU foam trainers. Many lines support private label and custom logo work, color covers, and printed graphics. A limited number can produce three-/four-piece urethane cover balls; prudent buyers validate with staged sampling and pilot runs.

How many golf balls does China export each year, and to which countries?

Shipments are roughly 280–290 million pieces annually with value in the low-hundreds of millions USD (latest full year, e.g., 2023). The United States and South Korea lead demand by both pieces and value, followed by Japan and the United Kingdom. These volumes set a conservative floor for installed capacity and demonstrate sustained international pull for mid-tier and RANGE products.

Where are China’s main golf ball manufacturing hubs?

Focus on Guangdong for volume and automation, Fujian for agile custom and gift configurations, and Zhejiang for promotional/e-commerce assortments. These zones benefit from proximity to plastics, molds, coatings, pad/UV printing, and seaports—reducing logistics friction and enabling integrated finishing.

| Province | Product focus | Key features | Example cities |

|---|---|---|---|

| Guangdong | Practice & mid-range | Volume + automation | Dongguan, Shenzhen |

| Fujian | Gift & custom orders | Flexible MOQs | Xiamen, Zhangzhou |

| Zhejiang | Promo & e-commerce | Strong packaging/printing | Ningbo, Yiwu |

Are any international brands producing in China?

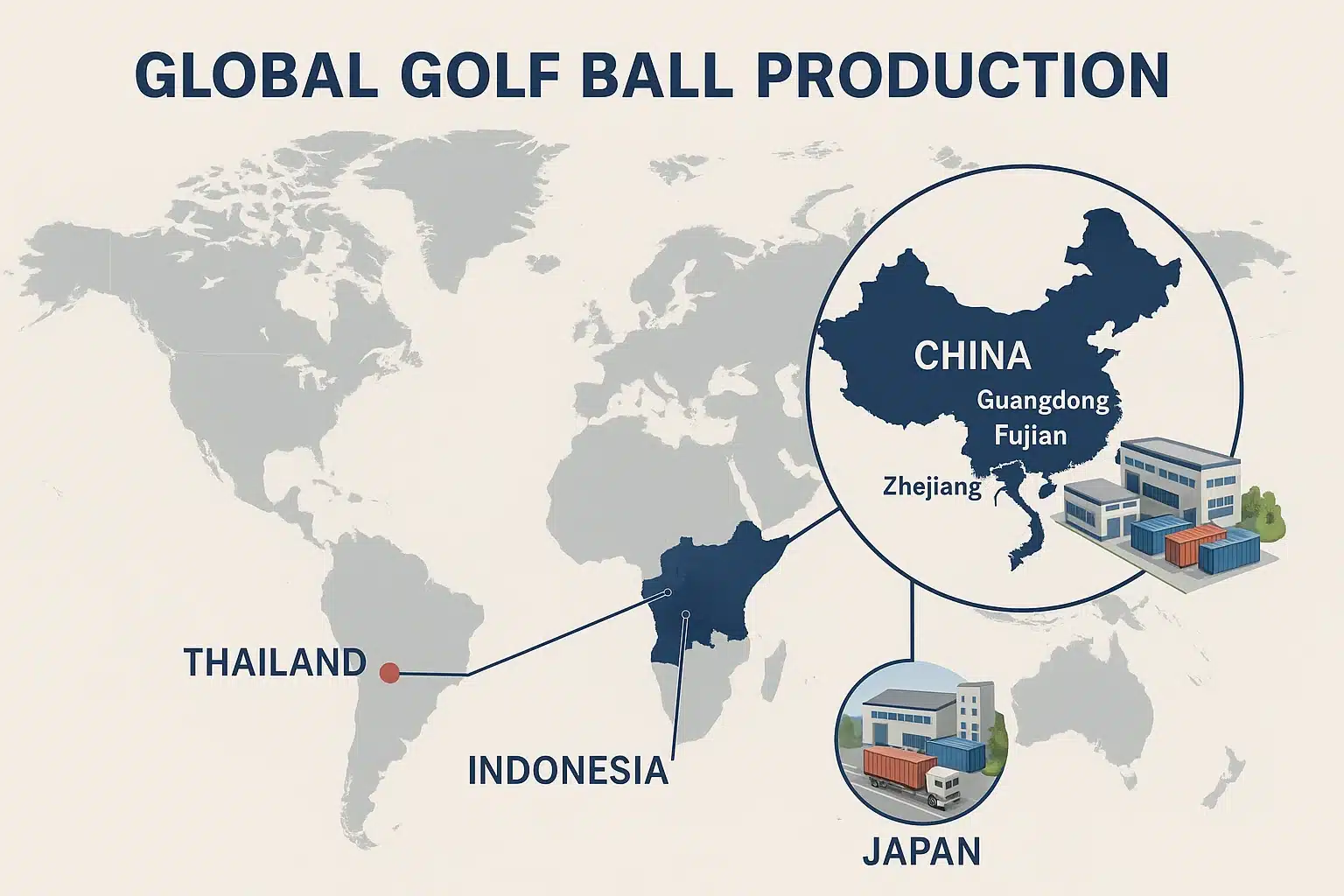

Top Tour-grade urethane flagships from major brands are primarily made outside China (e.g., US, Japan, Thailand, Indonesia, Taiwan) within owned or long-term partner networks. China mainly undertakes Surlyn entry/mid, RANGE, promo, and private-label OEM programs under standard confidentiality.

✔ True — Multiple countries make golf balls at scale

China, Thailand, and Indonesia are major suppliers alongside the US and Japan, with portfolios split by model tier and material systems.

✘ False — “All golf balls are made only in the US or Japan”

Global sourcing is diversified; model tier often dictates geography.

Can Chinese-made golf balls match the quality of top brands like Titleist or Callaway?

For two-/three-piece Surlyn, Chinese factories match mainstream brand consistency and durability. For multi-layer urethane “Tour” balls, outcomes depend on resin pedigree, cover-thickness control, and process capability (CPK) across long runs—so staged validation is essential.

Surlyn constructions benefit from mature cores, stable mantles, and robust coatings with predictable compression ratings. Urethane raises the bar: thin covers require precise cure windows and strong interlayer adhesion. The practical path is an engineering sample → robot test → pilot lot sequence that confirms speed/spin dispersion and surface durability before scaling.

Comparison: Surlyn vs PU multi-layer capability in China

Surlyn lines are widespread and repeatable, ideal for value and mid-tier SKUs with reliable flight windows. Urethane lines exist but vary in material systems and tooling control. To target Tour-like performance, lock cover thickness, concentricity, COR, and compression rating bands—and demand lot-level stats.

Why Tour-grade PU balls are harder to mass-produce

Urethane covers rely on tight thermal/catalyst cure, adhesion at each interface, and precision molds to hold thin cover uniformity. Small drifts in temperature or dwell alter wedge-spin and feel. Maintaining CPK on weight, diameter, roundness, and cover thickness through extended takt time is the real challenge.

How to test golf ball consistency and spin performance

Specify a test matrix: weight/diameter checks, compression (e.g., 75/85 ±3–5), COR/initial velocity, and concentricity. Add driver and wedge robot testing for speed/spin/dispersion, plus abrasion and paint adhesion trials. Archive retained samples and require statistics by lot on all CTQs.

✔ True — Mid-tier performance is mature

Two-/three-piece Surlyn from China can match big-brand benchmarks. Tour-grade urethane demands tighter material/process control and verification.

✘ False — “Chinese balls can’t reach pro-level”

They can in select cases, but require disciplined validation and SPC.

Are Chinese-made golf balls USGA or R&A compliant?

Yes. Conformity is model- and marking-specific, not country-based. Many Chinese OEM models appear on the USGA/R&A Conforming Golf Balls list when submitted by brand owners; if your exact model/marking is listed and current, it’s tournament-legal.

The lists verify weight, size, symmetry, and initial velocity. Factories are not named; only the model and stamping appear. If construction or marking changes, resubmission is required. Treat conformity as a hygiene gate: capture listings for the precise mark/graphic that will ship, and recheck monthly updates.

How does the USGA/R&A listing system work?

The submitter sends samples; once approved, the model/marking is listed. Keep documentation current, especially if variants (color/mark) differ. For seasonal programs, reconfirm the listing before events and archive PDFs for referees and distributors.

Can a Chinese-made ball be tournament-legal?

Yes—provided the exact model/marking is present on the current list at the time of play. Country of origin is irrelevant. For private-label SKUs, ensure the final artwork and stamping match the approved submission.

What other certifications indicate factory professionalism (ISO, BSCI)?

Seek ISO 9001 for quality systems, BSCI/SEDEX for social compliance, and evidence of process capability (e.g., CPK on diameter/weight/cover). Combine these with conformity listings to judge execution beyond a single lab pass.

✔ True — Listings are model-specific

USGA/R&A post only the model names and markings that pass. Factory locations do not appear.

✘ False — “USGA lists factories”

Compliance attaches to the ball model and its stamping.

What is the price range of Chinese-made golf balls?

FOB China pricing ranges from $0.19–$0.35 for PU foam trainers and $0.21–$0.50 for RANGE Surlyn, up to $1.2–$2.5 for three-/four-piece urethane “quasi-Tour.” MOQs run 1,000–10,000 pieces, with first-order lead times of 20–55 days depending on finishes.

Prices vary by finish, volume, packaging, and seasonality.

Indicative FOB prices (USD/pc), updated: Mar 2025; actuals vary by finish, volume, and packaging.

Pricing reflects structure (two-/three-/four-piece), cover (Surlyn/TPU/urethane), coating stacks, printing complexity, and packaging. Urethane programs carry higher materials, tooling wear, yield management, and QC overhead—especially when targeting narrow tolerances for top-tier feel and spin windows. Printing complexity and colorways can also stretch both price and schedule.

| Type | Structure | Indicative FOB (USD/pc) | MOQ | Lead time |

|---|---|---|---|---|

| PU foam / sponge | PU foam | 0.19–0.35 | 1,200–5,000 | 20–30 days |

| RANGE (Surlyn) | 2-piece | 0.21–0.50 | 5,000–10,000 | 25–35 days |

| Entry / Mid Surlyn | 2–3 piece | 0.35–0.80 | 1,000–5,000 | 25–40 days |

| Gift / Logo | 2–3 piece + print | 0.39–0.70 | 1,000–5,000 | 25–40 days |

| PU “Quasi-Tour” | 3–4 piece | 1.2–2.5 | 1,000–5,000 | 35–55 days |

✔ True — Price tracks structure and finishes

Layer count, cover chemistry, coatings, and printing drive both cost and schedule.

✘ False — “Cheaper means poor quality”

Lower pricing often reflects simpler builds or larger runs, not poor execution.

Are there reliable Chinese OEM factories for logo or small batch orders?

Yes. Many factories support 1,000–3,000 piece MOQs for custom logo or gift sets, integrating pad/UV printing, coatings, and packaging. At 3,000–5,000, you unlock more colorways and special finishes; first orders typically run 25–40 days from artwork lock to PSI.

For corporate gifting and retailer programs, integrated design-to-carton workflows accelerate approvals and stabilize Pantone matches across panels. Expect support for vector artwork, position guides, and white underbase where needed. Private-label and ODM templates can compress calendars for seasonal drops.

Typical MOQ and customization options

Plan 1,000–3,000 for standard logos and 3,000–5,000 for multi-color UV, special coats, or curated gift boxes. Packaging dielines and barcode/label compliance are usually templated, which reduces prepress friction and rework risk.

How long does it take to produce custom logo golf balls?

Allow 25–40 days for new programs (tooling checks, coating/printing proofs, packaging approvals). Reorders cycle faster once inks and fixtures are dialed. Peak seasons and complex finishes may add buffer for curing and QA.

OEM vs ODM: what’s the difference?

OEM builds to your BOM—layers, cover, compression rating, dimples, coatings, and graphics. ODM offers factory designs you can brand and tweak. Many buyers start ODM for speed, then migrate to OEM structures as volumes and performance targets mature.

✔ True — Small, flexible runs are common

Chinese factories routinely accept 1,000–3,000 piece logo programs with integrated printing and packaging.

✘ False — “Only large orders are possible”

Logo and gifting lines are engineered for agility and quick approvals.

How to choose a trustworthy golf ball manufacturer in China?

Select factories with integrated molding-to-packaging lines, proven export history, ISO/BSCI audits, and visible SPC. Lock a clear BOM early—layers, cover, compression rating, dimple count, coatings, and packaging—and require engineering samples, a pilot run, and defined AQL/PSI before mass orders.

Shortlist hubs in Guangdong/Fujian/Zhejiang with in-house finishing and carton lines. Request ISO 9001, BSCI/SEDEX, USGA/R&A listing screenshots (where relevant), and recent yield/rework/CPK snapshots on diameter, weight, and cover thickness. Fix FOB port, artwork cutoffs, and PSI windows in the PO.

Define your BOM: layers, cover type, compression, dimple count

A precise BOM removes ambiguity and accelerates approvals. Include structure, cover chemistry (Surlyn/TPU/PU), target compression (e.g., 75 or 85), dimple geometry, coating stack, print positions, and packaging spec with Pantone references.

Verify factory capability & past compliance records

Audit molding, coating booths, curing ovens, and pad/UV lines. Review calibration logs for scales/gauges and confirm retained-sample procedures. Ask for recent conforming golf balls list screenshots matching your intended marking.

Sample, test, and pilot-run before mass order

Run engineering samples to confirm feel/dispersion, then a pilot lot (>1,000 pcs) to validate repeatability under production takt. Capture lot-level statistics and retain golden samples to anchor future QA.

Set clear contract clauses (lead time, AQL, PSI)

Lock Incoterms (FOB China), first-order lead times (e.g., 30–40 days), incoming material controls, and AQL for visual/functional checks. Add Pre-Shipment Inspection (PSI), penalties for late/non-conforming deliveries, and artwork freeze dates.

BOM & QC quick-check table

| Item | Example spec | Acceptable range / note |

|---|---|---|

| Structure | 2 / 3 / 4 piece | Per BOM |

| Cover material | Surlyn / TPU / PU | Thickness ±0.02 mm |

| Compression | 75 / 85 | ±3–5 points |

| Weight / Diameter | 45.93 g / 42.67 mm | Within USGA limits |

| Dimples | Count / depth per drawing | Match CAD |

| Coatings | Primer / Topcoat | Adhesion test pass |

| Printing | Pantone & positions | Match golden sample |

✔ True — Fast, expert communication is a quality signal

Responsive, technically specific answers reveal process control and market fluency. Consider this alongside price and schedule.

✘ False — “Best price equals best factory”

Execution quality—audits, integration, samples, and corrective actions—drives stable supply.

FAQ

Are golf balls made in China USGA-approved for tournament play?

Yes—if the exact model and marking appear on the current USGA/R&A conforming list, it’s tournament-legal regardless of origin.

Compliance attaches to the model/marking, not the country. Ask for the listing that matches your final stamping. Resubmit if the construction or mark changes, and keep PDFs handy for officials. Always recheck the monthly-updated USGA/R&A list before tournaments and archive the current PDF.

Which Chinese factories supply well-known DTC golf brands?

Many DTC brands source in China under OEM confidentiality; validate capability with audits, samples, SPC, and conformity records rather than chasing brand rosters.

Look for integrated lines, ISO 9001, USGA/R&A listings for similar builds, and lot-level stats. Pilot runs and independent robot tests reveal repeatability better than name-dropping.

What’s the typical lead time for custom logo golf balls from China?

Plan 25–40 days for first orders; repeats are faster once inks and fixtures are set.

Complex UV effects, metallic inks, or urethane covers may add cure and QA time. Freeze dielines early, approve pre-production samples quickly, and secure capacity ahead of peak gifting seasons.

How can I verify a factory’s real production capability?

Do a line audit, request yield/rework/CPK data, confirm ISO and USGA/R&A evidence, and run a pilot lot with agreed AQL and PSI.

Check molding/coating assets, maintenance logs, and retained-sample procedures. Define acceptance bands in the PO to reduce disputes and delays.

Is Thailand or China better for OEM golf ball production?

It depends on tier: Thailand/Indonesia often host high-end urethane programs; China excels at Surlyn entry-to-mid, RANGE, promo, and agile private-label packaging.

| Region | Sweet spot | Advantages | Watch-outs |

|---|---|---|---|

| China | Surlyn entry–mid, promo | Flexible MOQ, speed, packaging | Urethane consistency varies |

| Thailand/Indonesia | Urethane high-end | Brand-linked ecosystems | Higher MOQs, longer sampling |

Can Chinese factories make urethane “Tour-level” balls?

Yes, select lines can, but consistency varies; demand material disclosure, thin-cover control, and statistical proof before scale-up.

Set targets for cover thickness, concentricity, compression, and wedge-spin dispersion. Use robot testing and retain samples for traceability.

What’s the minimum order quantity (MOQ) for customized golf balls?

Common MOQs are 1,000–3,000 pieces for standard logos and 3,000–5,000 for expanded colorways or special finishes.

Lower MOQs are feasible for basic prints or foam trainers. Complex coatings or multi-position artwork often require higher MOQs or longer lead times.

Conclusion

China manufactures a wide range of golf balls—from practice and value Surlyn to private-label logo and “quasi-Tour” urethane—backed by mature finishing and export scale. If you define a precise BOM, audit integrated lines, and validate through staged testing, China can be a competitive, reliable base for your program.

You might also like — How to Choose a Reliable Golf Ball Manufacturer in China?