How to Certify Chinese Golf Balls for Tournament Use

If you buy or private-label golf balls from China and plan to sell into events, you must think like a rules official and a QA manager. Tournament legality is simple to confirm but easy to fumble in paperwork and change control. This guide shows you how to certify, budget, and keep compliance solid after approval.

What Does “Tournament-Legal” Mean for a Golf Ball?

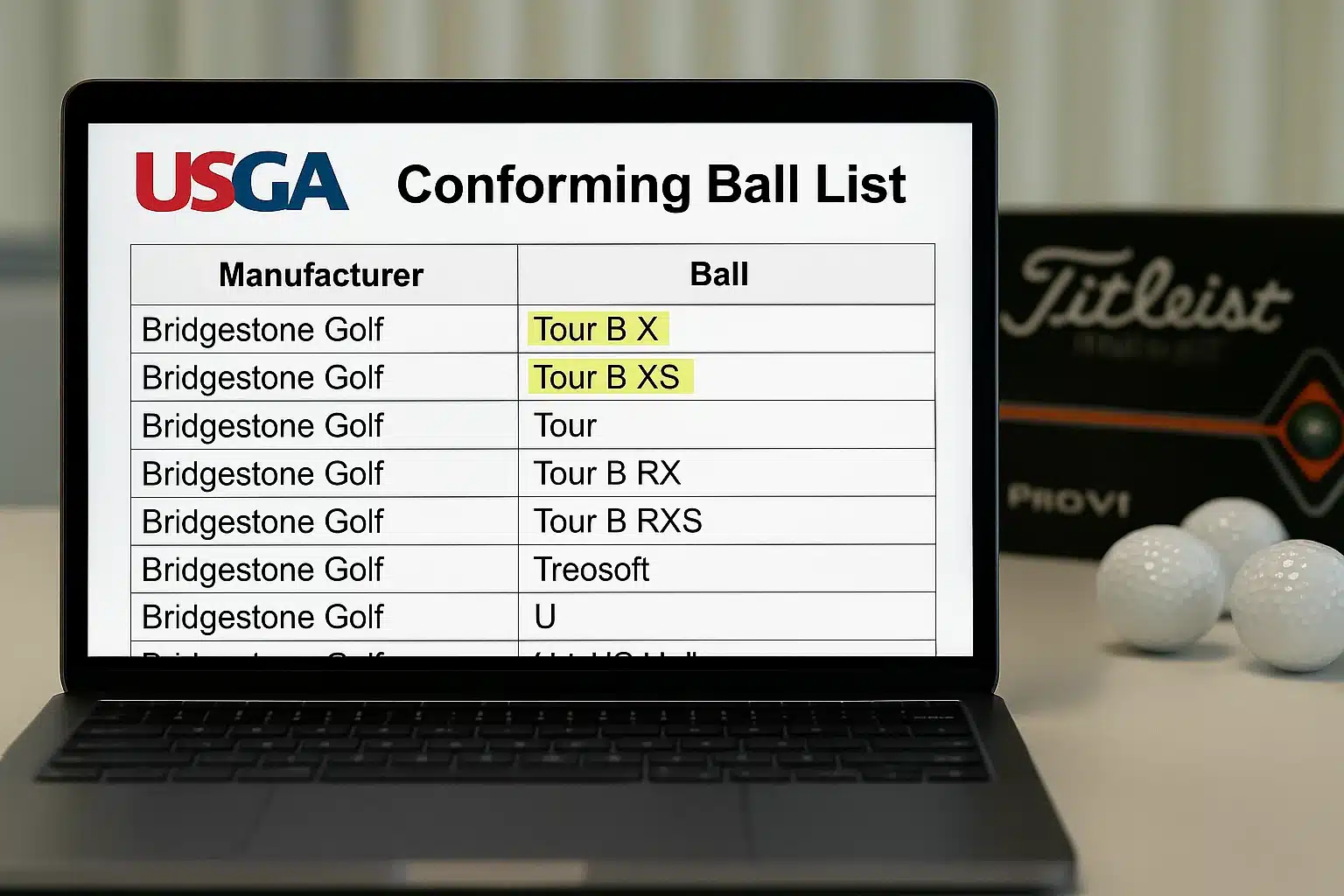

A golf ball is tournament-legal only if that exact model name appears on the USGA/R&A Conforming Ball List, meaning the submitted samples met size, weight, symmetry, and the Overall Distance Standard under the official test protocol. Approval is about the model, not factory, brand, or country—and it is not a holistic quality grade.

The USGA and R&A jointly publish a monthly PDF and database listing models that meet golf’s technical limits. Approval confirms that your submitted samples stayed within weight, diameter, symmetry, and the Overall Distance Standard (ODS) limits measured under controlled conditions. It does not grade feel, cover life, paint quality, or logo accuracy. Many buyers conflate “on-list” with “high quality.” Treat them separately: conformity is your entry ticket; quality is your brand promise.

Being listed protects you in scrambles, qualifiers, college circuits, and most federation events where a starter or referee can quickly verify model names. For casual retail or range balls, legality is often irrelevant. The decision is commercial—whether your ball must stand up to rulebook scrutiny where it’s played.

Table 1 — USGA / R&A Conforming Ball Limits

| Parameter | Requirement | Purpose |

|---|---|---|

| Weight | ≤ 45.93 g | Control distance |

| Diameter | ≥ 42.67 mm | Ensure fairness |

| Symmetry | Must be uniform | Flight stability |

| Overall distance | ≤ 317 yd (under ODS) | Performance cap |

✔ True — Certification ≠ Quality Judgment

USGA/R&A approval verifies test results from a submitted batch against technical limits. It does not rate durability, paint integrity, or brand-side QA systems.

✘ False — “Certified models are always better-built than non-certified models”

Some Chinese factories skip certification for cost reasons while maintaining production QC comparable to listed models.

Who Needs to Certify Golf Balls—and When?

Certification is required when your ball will be used in professional, collegiate, or federation-sanctioned tournaments. OEMs and private-label brands must certify each distinct model name before event use. For ranges, promotions, or general retail without competitive play, listing is optional and purely a business choice.

Event operators rely on the Conforming List to standardize equipment. If you supply teams, golf shops at tournament venues, or schools, listing avoids awkward disqualifications. If your channels are corporate gifts or driving ranges, you may never be asked for a list screenshot. Align the decision with where—and how—your buyers actually play.

OEM vs brand ownership of listing

Decide who owns the listing and model name. If the OEM lists under its brand, you can white-label only when the construction and model name you sell match the listing precisely. If you want exclusive control, submit under your brand’s model name and keep the BOM frozen with the factory.

Competitive vs practice use

Tournament balls must be listed; practice balls rarely need to be. Some programs split SKUs: certified for varsity competition, non-listed for daily range abuse. That keeps budget pressure off your event inventory while maintaining legality on game day.

Global recognition of one list

The USGA and R&A share a unified database. A listing recognized in the U.S. is recognized in R&A jurisdictions, and vice versa. You don’t need to certify twice if the model name and construction remain identical.

✔ True — Skipping certification doesn’t imply low quality

Domestic or recreational markets often don’t need USGA/R&A listing. Many factories avoid the annual fee where customers won’t compete in sanctioned events.

✘ False — “Unlisted equals non-compliant”

A ball can be unlisted yet still conform dimensionally; it just hasn’t been submitted and published.

One-line note for North American play: NCAA, NAIA, NJCAA, and many NFHS/HS leagues reference the same Conforming List; verify the current monthly PDF before championship or qualifier play.

How Does the USGA/R&A Certification Process Work?

Submission and publication follow a monthly cadence. You submit 12–36 identical samples, model documentation, and fees. The governing body tests weight, diameter, symmetry, and conformity under the Overall Distance Standard (ODS). Passing models appear in the next monthly Conforming Ball List update. Keep construction consistent—any change triggers re-evaluation.

Treat the submission like a controlled experiment. Samples must come from the intended production batch, not a hand-selected prototype. Label inner boxes with compression, cover type (Surlyn/ionomer or urethane), dimple count, and mold cavity IDs if available. Your application ties a public model name to a specific internal build, which you must keep stable.

Table 2 — USGA / R&A Certification Timeline & Tasks

| Step | Responsible | Time | Notes |

|---|---|---|---|

| Sample prep | OEM | 1 week | Use production batch |

| Form + fee | Brand | — | Online submission |

| Lab testing | USGA/R&A | 6–8 weeks | Physical conformity |

| Listing | USGA/R&A | Monthly | Public PDF |

Plan around closing dates. Submissions received late in a cycle may slide to the following month’s list. Add a two-week buffer for any clarifications or retests before your target event window.

What Does It Cost to Certify a Golf Ball Model?

Budget roughly USD 1,000–1,500 per model per year for listing fees (as of 2025), plus USD 500–800 for samples and shipping. You’ll renew annually. If you change core, mantle, cover, dimple pattern, or key process parameters, expect re-testing requirements that reset timing and cost exposure. Consider whether color/finish variants require separate entries.

Costs are modest versus a season’s margin, but they add up across SKUs and cover variants. For brands with three core constructions across two covers (Surlyn and urethane), annual listing can span multiple entries. Many buyers rationalize to a “tournament pack” while keeping practice/range balls outside the list.

Table 3 — Typical Certification Costs & Renewal Cycle (as of 2025)

| Item | Cost (USD) | Frequency | Notes |

|---|---|---|---|

| Listing fee | 1,000–1,500 | Annual | Per model |

| Sample / shipping | 500–800 | Per submission | Testing |

| Color/Finish variants | — | Case-by-case | May require separate entry |

| Processing time | — | 6–8 weeks | Average |

If you’re new to certification, treat year one as a pilot. Start with your flagship model where sanctioning matters most, collect feedback from teams and pros, then expand.

Can Chinese OEMs Handle Tournament Certification for You?

Yes. Established OEMs in Guangdong, Fujian, and Zhejiang routinely submit to the USGA/R&A. They can guide the paperwork and even license an already-approved build, provided the construction and model name you sell are identical to the listed version. Keep change control tight to avoid invalidation.

📍 Golfara Case (first-hand context): At Golfara, our two-piece Surlyn and three-piece Surlyn constructions were approved by the USGA in 2023, and our three-piece urethane model is currently under review. This matters for coaches and retailers who need a trusted, on-list option without building from scratch.

When partnering, align on who owns the listing, who pays renewal, and how deviations are handled. Clarify what counts as a “change”—switching ionomer grade, altering mantle hardness, or tweaking dimple tooling can all trigger re-evaluation. Make your OEM a co-owner of compliance, not just a producer.

✔ True — Approval proves model capability, not factory rank

A certified model demonstrates that a specific build can meet the limits. It does not automatically place one factory above another in quality systems or yield.

✘ False — “Only factories with listed models can make conforming balls”

Non-listed factories may hold equal tolerances and QA; they just serve non-tournament channels.

What Documents and Data Should Buyers Lock In?

Freeze the certified build in your contracts. Bind materials, molds, hardness targets, and process windows. Require a certificate of analysis per batch, retained-sample archives, and a formal change-control procedure. That’s how you ensure delivered mass production matches the model the lab approved.

Paperwork saves tournaments. Your purchase order should include the exact model name as listed, the BOM with resin grades and shore hardness targets, compression range, dimple count/ID, and coating specs. Ask for a COA with each lot covering weight, diameter minima, compression mean and standard deviation, and any in-house COR or speed data.

Table 4 — Buyer QA Documents for Certified Models

| Document | Purpose | Owner |

|---|---|---|

| Model data sheet | Proof of listing | OEM |

| COA per batch | Traceability | OEM |

| Retain samples | Re-test backup | Buyer & OEM |

| Change log | Risk control | OEM |

Include audit rights to inspect gauges (compression testers, balances, micrometers), calibration records, and in-process sampling plans. A two-page QA addendum integrated with your PO is often enough.

What Happens if Your Model Isn’t Renewed or Lapses?

If a listing lapses, the model disappears from the public list. However, real-world ball performance doesn’t change if no material, mold, or process shifts occurred. Renewal is administrative. You can re-submit the same build later; just avoid selling it as “tournament-legal” during the gap.

A lapse typically happens when a brand rotates portfolios, misses email reminders, or pauses a SKU for a season. The technical risk shows up only if the factory quietly altered the recipe. That’s why you lock the BOM and require change logs. In the field, referees check the list, not your lab notes; stay current to avoid disputes at the first tee.

✔ True — “Lapse ≠ Non-conforming”

Performance remains the same if the build stays the same. The listing simply isn’t visible until renewal or re-submission is processed.

✘ False — “A lapsed model becomes illegal forever”

You can restore status by renewing or re-testing under the original construction.

Common Mistakes Brands Make When Seeking Certification

Most failures stem from prototype samples, mid-cycle material tweaks, or incomplete documentation. Use mass-production batches, freeze the BOM, and keep full test records with photos of stamps and packaging. That discipline prevents retests, protects timelines, and keeps your season launch intact.

Prototype balls can be “too perfect,” hiding natural spread you’ll see at scale. The lab wants the real thing. Equally risky: swapping ionomer lots or paint systems mid-process. Even if on-paper specs match, micro-changes can shift ODS outcomes. Keep a living change log and escalate any deviation before shipping the next submission.

Table 5 — Typical Certification Errors and Prevention Tips

| Mistake | Result | Prevention |

|---|---|---|

| Prototype sample | Test failure | Use mass batch |

| Material change | Listing void | Freeze BOM |

| Missing records | Delay | Keep COAs + photos |

A short internal gate—BOM check, COA check, visual check—before each submission keeps everyone honest and saves weeks.

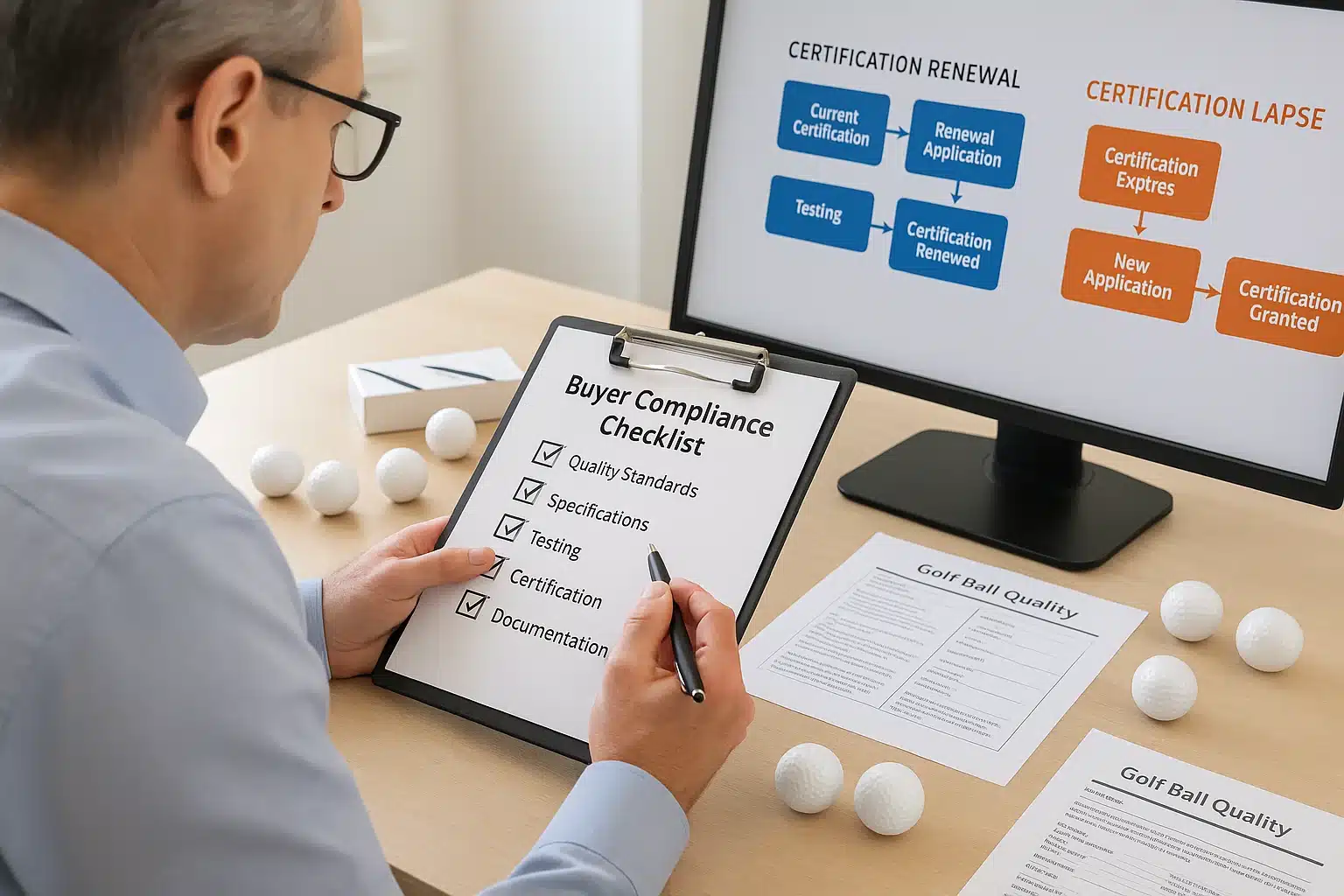

Buyer Checklist:Ensuring Tournament-Level Compliance

Before you commit, confirm the exact model name on the Conforming List, verify the factory’s lab gear and calibration, review compression and symmetry data, and lock technical specs and AQL in your PO. Create a retained-sample set and a change-control clause to protect every future delivery.

-

Confirm the exact model on the current monthly list.

-

Verify lab gear & calibration at the factory.

-

Test 12-ball weight/diameter/compression spread independently.

-

Lock BOM/tolerances/AQL + retain samples in your PO.

A buyer-friendly flow: 1) list screenshot in the quote file, 2) 12-ball independent check for weight/diameter/compression spread, 3) factory audit of instruments, 4) QA addendum pinned to your PO, 5) dual-retain samples with serialized labels. This sequence takes days, not months, and pays off when referees ask questions on-site.

Table 6 — Tournament Compliance Checklist for Buyers

| Step | Verification Method | Responsible |

|---|---|---|

| Confirm listing | Screenshot PDF | Buyer |

| Independent test | 12-ball sample | OEM + Lab |

| Audit equipment | Compression & COR tester | Buyer |

| Contract lock | BOM + AQL clause | Both |

Add a season calendar to your plan. Work backward from your first event, reserve 6–8 weeks for lab time, and pad two extra weeks for any re-tests. That way your inventory lands before qualifiers begin.

FAQ — Certification & Tournament Legality

How long does approval take?

Most approvals complete in 6–8 weeks after the lab receives your samples. Rushes are uncommon, so plan accordingly.

Expect a queue. Your timeline depends on the completeness of your documents and the stability of your samples. Use production-run balls and include clear model labeling. If you’re targeting a specific event window, submit two months ahead, plus a buffer for resubmission if parameters drift.

Can one listing cover two brands?

Only when the model name and construction are identical, and the ownership terms allow it.

The Conforming List ties approval to a specific model name and build. If your private-label program shares the exact construction and uses the same name as the listed entry, you can rely on that listing—subject to your OEM’s permission. Rename or rebuild, and you’ll need a fresh submission.

Do USGA and R&A lists differ?

No. They share a unified database, so one listing covers all jurisdictions.

The USGA and R&A coordinate equipment rules. A model listed via either authority appears in the common database and the monthly PDF. That simplifies global launches and avoids double fees. Just keep the construction consistent; deviating for “regional” specs can trigger re-testing.

How many balls must be sent?

Typically 12–36 per model, from the intended production batch.

The exact count depends on the program’s sampling plan, but you should plan for at least a dozen. Pull from normal mass production, not pilot lots. Include labels indicating cover type, core count, and dimple tooling. Keep duplicates as retained samples for any dispute or retest.

What if the OEM changes materials?

The listing becomes invalid; re-testing is required before tournament claims continue.

A new ionomer grade, altered urethane prepolymer, different mantle hardness, or a revised dimple mold can shift ODS outcomes and symmetry. Close the loop with a change-control clause: the OEM must notify you in writing and pause “tournament-legal” claims until a re-test confirms conformity.

Are Chinese balls eligible?

Yes. Legality is model-based, not country-based.

A Chinese-made model is as eligible as any other. The lab checks physics, not passports. Many Chinese OEMs already maintain listed SKUs and can assist with submissions. Your job is to fix the build in contracts, verify data, and keep renewals current as you scale sales.

Do color or finish variants require separate listing?

Sometimes. If the model name and construction are unchanged, cosmetic variants may not need a new entry.

Changes that affect construction or performance—like a different coating system that alters mass or surface—should be re-submitted. When in doubt, confirm with USGA/R&A before making “tournament-legal” claims. If you rebrand or rename the model, plan on a fresh listing aligned to the new name.

Conclusion

USGA/R&A certification confirms that a model—not a factory—meets tournament rules. Partner with experienced OEMs like Golfara, lock your certified build in the contract, and renew annually to remain visible on the list. Remember, approval signals technical conformity; your ongoing QA systems protect real-world quality and reputation.

Many Chinese factories do not apply because their customers do not need sanctioned-play eligibility. That commercial choice does not imply inferior quality—certification validates rules conformity only, not overall manufacturing excellence.

You might also like — Do China Made Tour-Level Golf Balls Meet USGA Standards?