You’ve decided on the golf ball spec, but packaging is still a blank page. Sleeve or dozen box? Giftable or compact? Every choice changes your shelf impact, freight bill and brand story.

Custom golf ball packaging uses 3-ball sleeves and 12-ball dozen boxes to balance brand impact, protection and landed cost. Sleeves are flexible, gift-friendly units; dozen boxes maximise retail and FBA efficiency. The best mix for your brand depends on channels, budget and sustainability priorities.

In the rest of this guide, we’ll break down how sleeves and dozen boxes are built, what they cost you across the whole supply chain, and how to match each option to your specific sales channels and ESG goals.

How are golf ball sleeves and dozen boxes structured?

Many buyers talk about sleeves and dozen boxes without realising they are just two building blocks of the same system. If you don’t nail the structure and dimensions early, everything from shelf fit to FBA fees can go sideways.

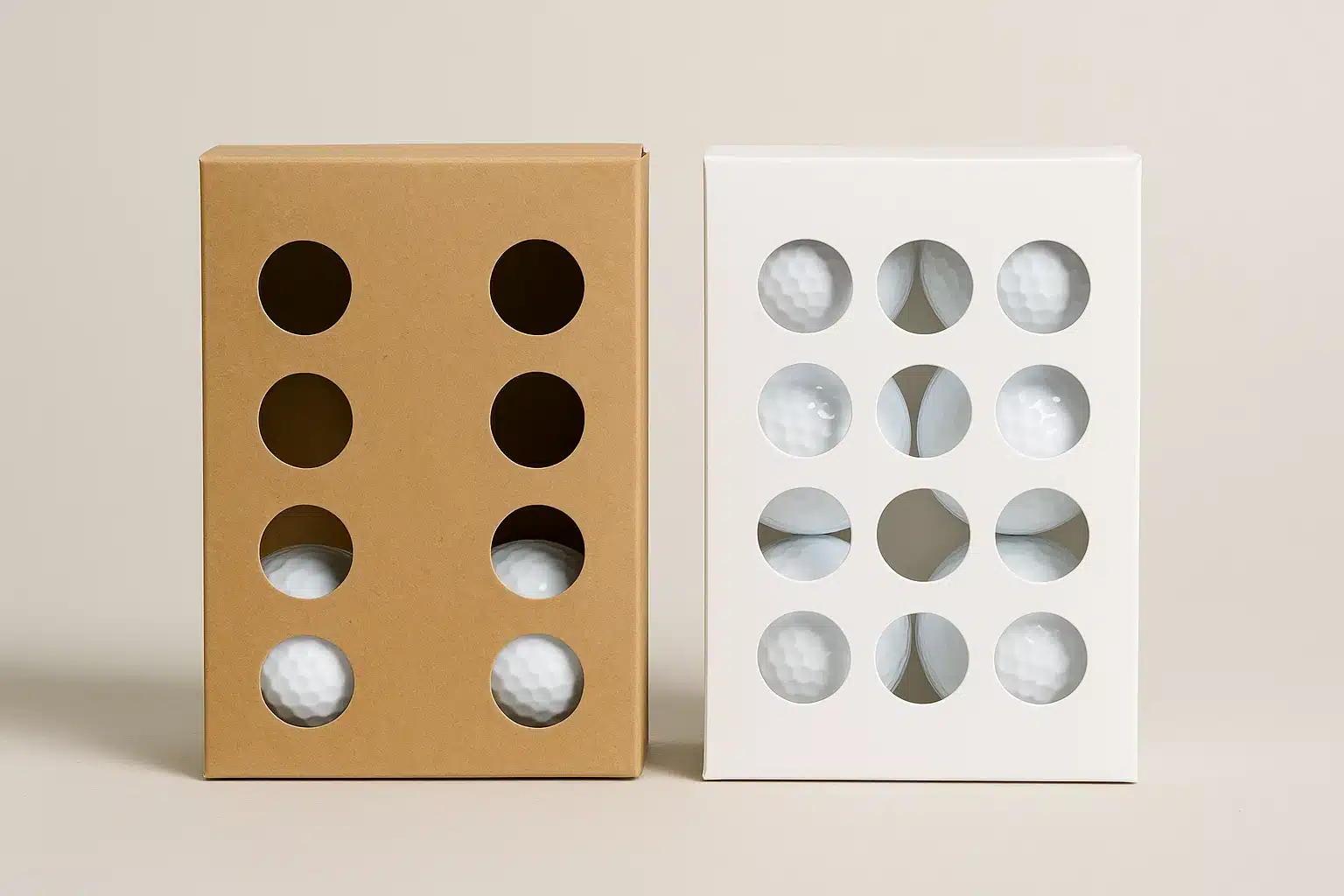

A 3-ball sleeve is a narrow folding carton holding three balls in a row, while a dozen box is a compact outer carton holding four sleeves (12 balls). Typical sleeves are around 127 × 44 × 38 mm and dozens about 190 × 140 × 45–50 mm, giving each cavity at least 43–44 mm internal width for balls that must be ≥42.67 mm under USGA/R&A rules.

Because most tour-style balls sit close to 43 mm, that extra millimetre or two absorbs board thickness and tolerances and explains why sleeve proportions look similar across brands. The classic “Titleist-style” build uses four sleeves inside one dozen, usually in a 2×2 grid for a book-shaped box that stacks efficiently in master cartons and on pallets. A 1×4 layout is possible but less space-efficient in shipping.

Sleeve and dozen are also different sales units. Sleeves work for giveaways, tournaments and starter packs; dozens are the main paid SKU for pro shops, retail and Amazon. Designing sleeves first and then building the dozen around them lets you keep artwork consistent while adapting the sales unit to each channel.

Structurally, sleeves and dozens are tuck-end folding cartons that ship flat and are erected at the factory. Rigid “setup” boxes appear as outer shells for premium gifts, but the compact sleeve–dozen system usually does the real work in logistics and everyday retail.

✔ True — Sleeves and dozens are modular building blocks

Sleeves can be sold alone, nested into dozens or combined into gift sets. That modularity is why brands treat sleeve design as a core asset, not just a ‘miniature box’.

✘ False — “A sleeve is just a tiny version of a dozen box”

If you simply shrink a dozen-box layout down to sleeve size, you usually lose readability and branding impact. Designing sleeves first, then the outer carton, gives you much more control.

5 Benefits of custom 3-ball sleeves

Here are five reasons brands still rely on custom 3-ball sleeves, even when the main sales unit is a dozen box. Together they make sleeves one of the most flexible tools in your packaging system.

- Flexibility for tournaments and corporate gifting (single sleeves as giveaways or prize inserts).

- Lower entry ticket for DTC shoppers compared with a full dozen.

- Extra branding surfaces when four sleeves sit inside one dozen box.

- Easy to mix models or colours in multi-sleeve packs without changing the outer carton.

- Good fit for vending machines, starter kits and pro shop impulse displays.

How should you choose materials for sleeves and boxes?

You want packaging that feels premium in hand but survives freight, pro shop handling and maybe even Amazon’s drop tests. Without the right board and finish, your brand can look cheap—or your cartons can arrive crushed.

Most golf ball sleeves and dozens use white cardboard (FBB/Ivory Board), duplex board, kraft or rigid box board in roughly the 300–400+ gsm range. White board and higher GSM give crisper print and stiffer feel; duplex and kraft favour cost or eco aesthetics; rigid board is best reserved for outer gift boxes.

Think of GSM as thickness and stiffness. Around 300–350 gsm works for cost-focused retail and Amazon. 350–400 gsm feels more solid and copes better with stacking, which suits pro shops and premium private labels. Above 400 gsm, you are generally using rigid board for presentation boxes that sit on top of a compact dozen.

Material choice also carries a visual and ESG message. White cardboard is bright and smooth, ideal for sharp CMYK + Pantone print. Duplex (white front, grey back) is the classic “value” option when budget matters more than inner appearance. Kraft or recycled boards give a matte, natural look that fits plastic-free and “sustainable golf” narratives, especially with minimalist graphics.

Recyclability is now part of golf’s sustainability story. Tournaments and clubs are phasing out single-use plastics; switching from plastic windows and PVC trays to pure FSC-certified paperboard lets you align with that shift without exotic materials. The key is honest claims and clean structures, not magic buzzwords.

Rigid setup boxes are strong but travel pre-assembled, increasing freight volume. Using them as an outer shell around a compact dozen lets you deliver a VIP unboxing moment while keeping logistics based on efficient sleeve–dozen cartons.

✔ True — Plastic-free packaging can be cost-neutral or cheaper

Moving from plastic windows and trays to pure paperboard can simplify production, reduce FBA penalties on loose plastics and support ESG messaging without exploding your unit cost.

✘ False — “Eco-friendly always means much more expensive”

Costs depend on board grade, GSM and finishing. Often the real premium comes from complex foils and laminations, not from choosing FSC or recycled paperboard.

How does board thickness (GSM) change the feel?

Different GSM bands create very different first impressions in hand, so it helps to think in three simple ranges linked to channels and price points.

- 300–350 gsm – Lighter feel, acceptable for Amazon and price-sensitive retail. Good for 2-piece distance balls, ranges and promotions.

- 350–400 gsm – Noticeably stiffer; ideal for 3-piece or “tour-style” balls in pro shops and higher-end eCommerce.

- 400 gsm+ / rigid – Very firm, gift-like; best for corporate or VIP sets, usually as a shell around compact dozens.

Board options for golf ball packaging

| Board Type | Typical GSM Range | Look & Feel | Best For | Recommendation |

|---|---|---|---|---|

| White cardboard / FBB | 300–400 | Bright, smooth, premium print surface | Tour-style balls, pro shops, Amazon premium | Use for flagship SKUs and brand-critical art |

| Duplex board | 300–380 | White front, grey back, “mid-range” | Volume OEM, practice and range programs | Choose when budget is tight but print matters |

| Kraft / recycled board | 300–380 | Natural, matte, eco-forward | Sustainable golf and eco-led campaigns | Pair with plastic-free structures and simple art |

| Rigid box board | 400+ | Very stiff, gift-like | Corporate / VIP sets around standard dozens | Use as an outer shell over compact dozens |

Which printing and finishes best boost perceived value?

You can put a tour-level ball in a plain white box and it will still feel cheap. The right print and finishing stack is what makes your logo “pop” and turns packaging into shareable unboxing content.

You can absolutely put your logo on a golf ball sleeve—typically using CMYK plus Pantone spot colours—and then elevate it with finishes like spot UV, foil stamping, embossing and soft-touch lamination. A focused mix of one or two hero effects boosts shelf impact and unboxing appeal while keeping colour consistent across balls and boxes.

Most custom sleeves and dozens use CMYK with key elements in Pantone-matched spot colours. Logos usually sit on front, side and top panels so they stay visible whether the sleeve stands or lies flat. When the same OEM prints both balls and boxes, everything can be tied to shared Pantone references so nothing looks “almost right.”

Colour consistency comes from measurement, not luck. A typical target is a ΔE2000 of 2–3 against the master swatch, which is tight enough that most eyes won’t see a difference, even across urethane covers, white board and soft-touch lamination.

Special finishes then make the packaging feel premium and camera-friendly:

-

Spot UV / gloss for shiny contrast over matte areas.

-

Foil stamping for metallic logos or model names that signal technology or luxury.

-

Emboss / deboss for tactile relief on logos or patterns.

-

Soft-touch lamination for a smooth, velvet-like feel on dozens and high-end sleeves.

These finishes catch light nicely and look good in photos and short-form videos, which is exactly what you want if you plan to lean on Instagram, TikTok or DTC unboxing. Each extra effect adds plates, dies and passes, so most projects choose one hero effect and one supporting effect instead of a full “Christmas tree” of finishes.

✔ True — Soft-touch and special finishes can still be recyclable

Many paper streams accept soft-touch films and moderate foil coverage when they’re applied over paperboard, especially for small-format cartons like golf sleeves and dozens.

✘ False — “Any laminate or foil makes the box ‘non-eco’”

Recyclability rules differ by country. If you want strong eco claims, ask your supplier to align finishes with your main markets’ guidance instead of avoiding all finishing effects.

Designing for consistent brand colour across balls and boxes

For B2B buyers, colour control is one of the biggest reasons to work with an integrated OEM instead of splitting balls and boxes, because one team can manage Pantone, ΔE targets and proofs end to end.

- Use one Pantone master set for both ball print and packaging.

- Target ΔE 2–3 across substrates to keep colours visually aligned.

- For critical launches, ask for press proofs or on-press approvals on the first run.

How does packaging size affect cost and logistics?

Two boxes can hold the same dozen balls yet cost you completely different amounts to move. Over-sized gift boxes feel impressive, but they can quietly destroy your landed cost per dozen and FBA profitability.

Compact, book-style dozen boxes combined with flat-packed tuck-end sleeves let you move far more units per pallet or 40′ HQ container than oversized gift boxes. Because carriers and FBA use dimensional weight and size tiers, small reductions in carton size can reduce freight, storage and damage costs—provided the box still passes ISTA 3A/6-Amazon.com style tests.

A simple container example makes the point. A tight 24-dozen master carton around 40 × 30 × 30 cm can theoretically give you well over 40,000 dozens in a 40′ HQ, whereas a bulky gift configuration with only 12 sets per larger carton might drop you to roughly 10,000–11,000 units. So compact dozens can move about three to four times more retail units in the same space. This is an illustration only; every project needs its own simulation.

Carriers and FBA also charge based on dimensional weight. Golf balls are dense, so you often pay for the volume your cartons occupy. A few millimetres trimmed from height or width, or a smarter master-carton pattern, can move you into a better fee tier.

When someone asks, “How much does custom golf ball packaging cost?”, they usually mean cents per box. In reality, packaging also changes freight, FBA fees, prep work and damage rates. The number to track is all-in landed cost per dozen, not just ex-factory box price.

Working with Golfara gives two extra levers. Balls, sleeves, dozens and master cartons are designed together for carton density and FBA readiness, then kitted at the factory, saving destination labour and repacking errors. And when packaging MOQs are higher than your first ball order, Golfara can store surplus printed boxes for free, so you only ship and use what you need now.

✔ True — Freight savings are scenario-specific

Compact packaging can easily improve units per container by 20%–300% versus oversized gift formats, but the exact number depends on your final carton size and pallet pattern.

✘ False — “A smaller box always saves exactly 20%+ on logistics”

Every project needs its own volumetric and freight calculation. Use examples for direction, not as guaranteed savings, and ask your supplier to help model realistic scenarios.

How to estimate packaging’s impact on landed cost per dozen

Instead of guessing, you can use a simple three-step calculation to see how each packaging concept changes total landed cost per dozen.

- Step 1 – Box cost. Get ex-factory box costs per dozen for compact and gift-style ideas.

- Step 2 – Density. Confirm dozens per master carton and master cartons per pallet or container. Compare units per cubic metre.

- Step 3 – All-in. Allocate freight and FBA fees per dozen based on volume and weight, then add box cost. The concept with the lowest all-in cost per dozen is your real winner.

Sleeve vs. dozen box comparison

| Aspect | 3-Ball Sleeve | Dozen Box | Recommendation |

|---|---|---|---|

| Typical external dimensions | ≈127 × 44 × 38 mm | ≈190 × 140 × 45–50 mm | Confirm fit with your ball spec and shelf depth |

| Cost efficiency at scale | Slightly higher cost per ball | Best cost per ball at medium to large volumes | Use sleeves for flexibility; dozens for core volume |

| Retail / FBA suitability | Great for gifts and impulse displays | Ideal as main Amazon/pro-shop SKU | Lead with dozens; support with sleeves as needed |

| Shipping weight & volume | Light but inefficient alone in cartons | Highly efficient in master cartons and containers | Ship mostly dozens; combine sleeves inside dozens |

When should you choose sleeves, dozens or hybrid packs?

No single packaging format wins everywhere. The right mix depends on whether you’re chasing pro shop prestige, Amazon margin, tournament exposure or corporate gift “wow” factor.

Use sleeves when you need flexible 3-ball units for gifting, tournaments or entry-level offers; rely on compact dozen boxes as your main retail and FBA workhorses; and reserve rigid or layered gift packaging for high-end corporate and VIP projects. Match packaging level with ball construction and price band so the overall offer feels coherent and honest.

For corporate gifts and tournaments, a rigid or semi-rigid gift box wrapped around one or two compact dozens usually works best. Inside, you still use the standard four-sleeve dozen; outside, you get space for event branding and ESG messaging. The same dozen spec can then serve pro shops or Amazon without redesign.

In retail and pro shops, the compact dozen is the hero SKU. Sleeves support it as lower-ticket packs and promo vehicles that share the same design language. For Amazon and DTC, dimensional weight and damage risk dominate, so ultra-compact, strong dozens—sometimes in simple kraft outers—tend to win.

On the range and promotional side, 2-piece Surlyn balls often sit in simpler duplex or kraft sleeves and dozens. You can still highlight sustainability and brand identity, but you usually skip the heaviest boards and most complex finishes.

Ball construction doesn’t force you into a specific box, but it does shape expectations. Many brands put 2-piece balls into simpler cartons and use 3-piece urethane or “tour-style” balls with heavier white board and richer finishes so the perceived price band makes sense.

MOQ mismatches are common: carton MOQs are often higher than initial ball volumes. A typical pattern is producing about 1,000 dozens worth of custom boxes while only running 3,000–5,000 balls initially. Golfara uses part of those boxes to pack the first shipment and stores the rest for future orders—while handling all kitting at source.

Channel-based examples: corporate, retail and Amazon

The easiest way to see how these choices play out is to look at a few concrete scenarios in corporate, retail and Amazon channels.

-

Corporate buyer. Uses a 3-piece urethane ball in a compact dozen plus a rigid outer gift box and kraft bag. Golfara packs sleeves, dozens and gift sets at the factory so boxes arrive ready to hand out.

-

Retail brand. Leads with a compact dozen on pro shop shelves, using 350–400 gsm white board and one foil or spot-UV element. Matching sleeves support seasonal bundles and tournaments.

-

Amazon seller. Chooses ultra-compact dozens with strong tuck ends and minimal inner packaging, tuned to FBA size tiers. Artwork is optimised for thumbnails and unboxing photos rather than dense copy.

Packaging choices by channel

| Channel | Recommended Unit | Ball Type | Main Goal | Golfara Suggestion |

|---|---|---|---|---|

| Corporate gifts & tournaments | Dozen in rigid gift box | 3-piece urethane / tour-style | “Wow” factor and perceived value | Use compact dozen inside; add rigid shell and kitting |

| Retail & pro shop | Compact dozen box | 2- or 3-piece | Shelf impact and trade-up options | Standardise one dozen size; sleeves as promo accents |

| Amazon / DTC | Ultra-compact dozen | 2- or 3-piece | FBA profitability and low damage | Design around size tiers, ISTA tests and minimal void fill |

| Driving range / promotional | Sleeves or simple dozens | 2-piece distance | Volume and easy distribution | Duplex or kraft board with clear, bold branding |

How do you choose the right packaging partner?

A beautiful dieline is useless if the supplier can’t deliver on time, keep colours consistent or pack your balls correctly. You’re not just choosing a box—you’re choosing a partner for your whole go-to-market plan.

For most brands, the safest option is a golf ball factory that also manages packaging, kitting and logistics. One integrated partner is more likely to keep Pantone colours consistent, optimise carton density and avoid packing errors than a loose combination of ball supplier, print shop and 3PL. Evaluate factories on responsiveness, MOQ flexibility, test capability and channel fluency—not just on unit price.

An integrated packaging solution means one team owns the flow from ball core to export carton: ball moulding, ball printing, sleeve and dozen production, kitting and master-carton design. When something goes wrong, you have a single point of contact instead of three vendors blaming each other. It also means packaging decisions are made with real knowledge of ball specs, channels and freight constraints.

China’s golf-ball clusters in Zhejiang, Fujian and Guangdong are built around this logic—specialist ball plants working closely with packaging converters and logistics partners. That ecosystem lets Golfara offer professional packaging and flexible MOQs, even when you’re still in test-launch mode.

When you vet suppliers, look for:

-

Integrated ball + packaging + kitting capability

-

MOQ flexibility for both balls and cartons

-

Fast, clear answers on GSM, Pantone, tests and FBA

-

Visible packaging examples—sleeves, dozens and gift sets

-

Willingness to suggest options rather than just ask for your spec

Ask specifically about QC and testing: drop and crush protocols, colour-control methods and whether they can share sample reports or photos. For Amazon or DTC projects, check that they understand FBA size tiers, prep rules and realistic master-carton layouts.

✔ True — A smaller, focused OEM can be the better partner

Mid-sized factories that specialise in golf balls and integrated packaging often offer more flexibility, faster feedback and closer engineering support than mega-OEMs.

✘ False — “Bigger factory automatically means better packaging”

For complex artwork, ESG goals and multi-channel portfolios, you often need attention and iteration speed more than sheer capacity. Match the factory’s profile to your project’s complexity, not just its volume.

FAQ

Even after understanding structures, materials and logistics, most buyers still have tactical questions about ROI, MOQ and compliance. This FAQ keeps the key ones in one place.

Is custom packaging worth it for private label golf balls?

Yes—custom sleeves and dozens are usually worth it for private label if the packaging level matches your ball tier and price point. Strong packaging supports better pricing, better unboxing content and more credible branding than generic or clear boxes.

Packaging is the first thing buyers and golfers see. When ball print, sleeve and dozen design line up, your product feels intentional, not like bulk balls in a random carton. That makes it easier to position your brand and hold margin. The key is alignment: value balls in ultra-luxury rigid boxes feel off; tour-level balls in plain white cartons leave money on the table.

What is the difference between a sleeve and a dozen box in practical terms?

A sleeve is a 3-ball unit ideal for gifting, tournaments and starter packs; a dozen box is the main 12-ball retail unit built from four sleeves. Most brands plan production in dozens and use sleeves as flexible modules.

You plan inventory and master cartons in dozens because they ship efficiently. Sleeves then give you options: you can sell them as lower-ticket packs, use them for tournaments or build variety bundles online. When sleeves and dozens share artwork, you keep SKU complexity under control while tailoring the sales unit to each channel.

How does packaging affect Amazon FBA fees for golf balls?

Packaging affects FBA fees through size tiers, dimensional weight and damage rates. Compact, strong dozens usually land in better tiers and need less extra prep than oversized or weak cartons.

Amazon charges based on your item’s dimensions and weight, so a few millimetres can move you between tiers. Dense products like golf balls hit dimensional-weight limits quickly. If your boxes crush easily, Amazon or your prep partner may add over-boxing or void fill, increasing cost and waste. Designing dozens and master cartons with FBA tiers and basic drop tests in mind is cheaper than fixing problems after launch.

What packaging durability tests should I ask my supplier to run?

Ask for loaded drop tests, basic compression or crush tests and simple transport-style simulations based on ISTA 3A/6-Amazon.com guidance. Your supplier should be able to describe the methods clearly.

The aim is to prove that fully loaded cartons survive typical handling and stacking without damaging balls or boxes. Drops check impact resistance; compression tests confirm boxes won’t collapse in containers or warehouses. For FBA-focused projects, link these tests to Amazon’s prep and packaging rules so you avoid chargebacks or forced repacks on arrival.

What is the cost difference between 350 gsm and 400 gsm board for golf ball boxes?

Moving from around 350 gsm to 400 gsm usually adds a modest cost per dozen, but the perceived upgrade can be big in pro shops and corporate settings. The exact delta depends on board type, finishing and volume.

Rather than assume, ask your supplier for two prices and two sets of samples on the same design. Compare price, stiffness and resistance to crushing. Many brands use heavier board on hero SKUs and keep 350 gsm or duplex for high-volume, price-sensitive lines so budget goes where it matters most.

What is the MOQ if I only want custom sleeves and boxes, but a small first ball order?

Custom sleeves and dozens often have higher MOQs than balls, but an integrated factory can bridge the gap by kitting at source and storing surplus boxes for future orders. This lets you test smaller ball volumes without wasting printed packaging.

A common pattern is producing roughly 1,000 dozens worth of cartons while only running 3,000–5,000 balls initially. Golfara uses part of those boxes to pack the first shipment and holds the rest in free storage. On your next reorder, packaging is ready, so you pay artwork and setup once and grow into the stock over time.

Can I mix different ball models or colours inside the same custom box design?

Yes, you can mix models or colours inside one sleeve or dozen design if the product story is clear and packing instructions are precise. Done well, this flexibility becomes a strength, not a risk.

Variety packs—distance plus spin, or mixed colours for events—are a good example. Decide allowed combinations upfront, reflect them honestly in the copy and manage packing through clear specs at the factory. When Golfara handles kitting, model and colour allocations are part of the packing plan, not improvised later in your warehouse.

Conclusion

Sleeve vs. dozen box isn’t really an either–or question. Smart brands design a system that lets both units work together across channels and seasons.

The simplest way to win the sleeve-versus-dozen debate is to standardise one or two compact core structures, then tune materials, finishes and optional gift layers by channel and ball tier. That keeps branding, logistics and ESG aligned while avoiding a long tail of expensive one-off box designs.

The most robust approach is to treat packaging as a small set of platforms, not a series of one-off projects. When you decide early how sleeves and dozens should work together—and involve an integrated OEM like Golfara in that decision—you gain tighter cost control, clearer ESG messaging and less friction every time you launch a new SKU or campaign.

You might also like — How to Start a Golf Ball Business on Amazon FBA (2025)?