Night golf is memorable—until balls don’t light, logos peel, or participants worry about damaging clubs. Bulk LED golf ball risk is manageable when you control three things: surface condition, activation consistency, and battery shipping paperwork. Turn those into sample proofs (photos + simple tests + a document set), and your night event feels premium instead of improvised.

This guide answers the top questions with buyer-checkable steps—so you can approve samples, prevent avoidable failures, and keep delivery on track.

Are LED golf balls safe for your driver?

For most corporate night events, LED golf balls are generally safe when the shell is smooth and defect-free—surface condition matters more than a single compression number. Many products are described as mid-to-firm, but you should still approve samples and set a rule: don’t use visibly scuffed or rough balls, and steer long-hitters to safer club choices.

When you’re buying bulk LED golf balls for a corporate night event, you’re not just buying a novelty—you’re buying peace of mind. The top fear buyers hear (and sometimes inherit from legal/ops teams) is simple: “Will these damage drivers?”

Here’s the practical reality: the clubface “feels” the outer shell, not the marketing copy. The most avoidable risk comes from what you can see—sharp seams, flash, burrs, embedded debris, or shipping scuffs that turn the surface abrasive. That’s why your first control should be a surface inspection routine, not an argument about numbers.

This is the acceptance rule you can document and audit before deposit (photos + sample hit notes).

| Risk factor | What you’ll see | Why it matters | How to verify | Acceptance criteria + next step |

|---|---|---|---|---|

| Seam sharpness / flash | Raised seam line, rough edge | Can increase abrasion on impact | Macro photos + fingertip check | Seam feels smooth; no sharp edge → approve / else reject |

| Burrs or embedded debris | Tiny “spikes,” dark specks | Point-load abrasion raises complaint risk | Magnifier inspection + wipe test | No burrs/debris → approve; any found → sort/replace |

| Shipping scuffs (rough patches) | Dull scuffs, scratches | Roughness increases friction and “clicky” feel | Open-carton spot checks + photo log | No rough patches → improve packing protection if seen |

| Construction disclosure | “Premium” with no details | LED module limits layering complexity | Request cross-section/cutaway | Construction stated (often 1–2pc) → set expectations |

| Player profile | Long-hitters vs casuals | Swing speed drives impact energy | Event guidance card | Long-hitters use irons/fairway woods → lower perceived risk |

| Temperature variable | Very cold balls feel harder | Cold affects feel and perception | Store at venue temperature | Keep cartons moderate temp before play |

✔ True — Surface condition is the safety lever you can control

A smooth, defect-free shell reduces abrasion and “unexpected harsh contact” more reliably than chasing a single compression number. Make seam/flash/burr/scuff checks part of sample approval and pre-shipment evidence.

✘ False — “Compression alone causes club damage.”

Compression scales aren’t globally standardized, and “firm-ish” doesn’t automatically equal harmful. In B2B buying, it’s safer to gate approval on visible shell quality and documented event usage rules.

Compression vs. Hardness: Why Material Choice Matters

Buyers often describe LED balls as “hard,” but “feel” isn’t one universal metric. Many LED light-up balls publicly described in the market sit in a mid-to-firm compression band (often cited around 70–80), and commonly referenced compression scales cover a wide range—so treat compression as context, not a guarantee.

What you can control is the shell: require construction disclosure (LED modules typically constrain builds to 1–2 piece structures), and run a simple “hit & inspect” routine on samples. If shells show abnormal roughening or sharp seams after use, tighten acceptance criteria or change the shell/finish process.

How do LED golf balls activate: impact or switch?

Impact-activated balls are simplest for large groups—hit the ball and it lights automatically—while switch models give you more control for staged starts and photography. To avoid “some don’t light” surprises, verify activation on samples and require packaging that prevents accidental lighting during shipping.

At a B2B night event, activation is operations. If a ball doesn’t light, participants don’t think “normal variance”—they think “cheap product,” and staff get pulled into one-off fixes. That’s why activation method should be chosen based on staffing and pace-of-play, not novelty.

Quick SOP: How to verify activation reliability (bulk orders)

-

Confirm the activation type (impact or switch) on the spec sheet—and keep the same wording on the outer carton.

-

Run a sample activation check using event-like hits (a putt + a full swing) and record pass/fail.

-

Time the “on” window with a visible stopwatch to confirm the claimed timer behavior.

-

Request packing proof (photo/video): inner separation and cushioning should prevent accidental activation in transit.

-

Set a swap rule for the event: if a ball doesn’t light normally, replace it immediately and don’t reuse damaged units.

📽️ Watch how our LED golf balls work in action (20s video):

How long do LED golf balls stay bright in real use?

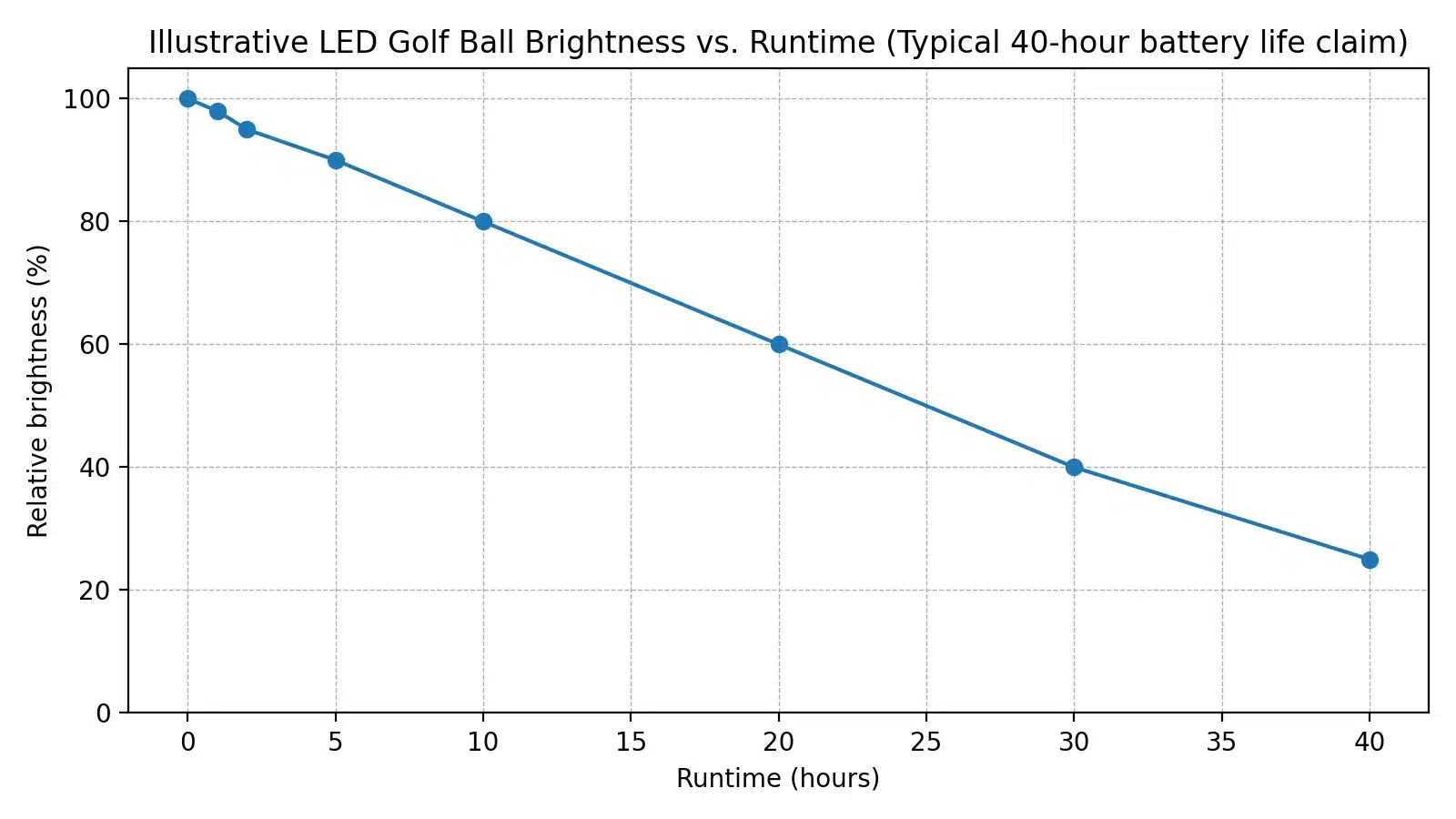

‘Total runtime’ usually means the LEDs remain usable across many activations, not that brightness stays constant from start to finish. Confirm the per-activation timer and the supplier-claimed total runtime definition on samples, then align stakeholders with a simple decay graphic so your event doesn’t over-promise peak brightness.

If you’ve ever heard “but it said ‘up to X hours,’” you already know the risk: people read that as “constant brightness for X hours.” Always treat “X hours” as a supplier-claimed total runtime definition to verify, not a universal guarantee.

A clean way to define this in writing (so everyone aligns):

-

Per-activation timer: how long the LED stays on after a hit/switch (verify with a stopwatch).

-

Total runtime: accumulated “on” time over many activations; brightness can fade gradually as the battery ages.

To verify in an event-relevant way, ask for (1) a timer test video with a visible stopwatch, and (2) a repeat-use demonstration that shows brightness perception after multiple cycles using a consistent camera setup. Your goal isn’t lab-grade photometry—it’s “does it still look usable for our venue and pace?”

Illustrative brightness decay curve for an impact-activated LED golf ball. ‘Total runtime’ typically means usable light up to that total, not constant brightness throughout.

✔ True — Define “usable brightness” for your venue

The right metric is whether players can find balls and keep pace under your lighting—not whether brightness stays at “peak” for the whole battery life claim. Approve samples using venue-like conditions and write the definition into your event brief.

✘ False — “Total runtime means constant brightness.”

Total runtime is typically cumulative “on” time. Brightness can decline over many activations, so manage expectations with a decay graphic and timer/running-time definitions in writing.

LED balls or glow-in-the-dark balls for your event?

Choose LED balls when you need predictable, easy-to-see light without extra equipment—best for big corporate groups and fast event pace. Choose glow-in-the-dark balls when you can manage UV charging and only need short bursts of visibility; if branding matters, approve how the logo looks both in daylight and under low light.

B2B teams often bundle “glow balls” into one category, then discover mid-event that visibility isn’t predictable. LED balls and glow-in-the-dark balls solve different problems, and the right choice depends on staffing and venue lighting.

Here are the procurement-friendly differences that actually affect outcomes:

-

Brightness workflow: LED gives consistent “on” behavior per activation; glow requires UV charging and fades quickly.

-

Staff workload: LED usually reduces intervention; glow needs charging stations and reminders.

-

Brand perception: you’ll be judged on how it looks unlit too—approve logo appearance in normal light and under low light.

If your venue has uneven lighting (tree lines, rough edges, water carry), LED tends to reduce ball-loss frustration. If you’re doing a short novelty segment with staff support, glow can be workable. Either way, request a side-by-side visibility photo/video in similar lighting, not just a studio image.

Which logo printing survives hits on glowing surfaces?

Pad printing is usually the safest choice for durable, spot-color logos on curved golf ball shells because it bonds well and resists scuffing. UV printing is best for complex full-color designs, but durability depends on surface prep and protection—so approve by adhesion checks and after-hit photos, not fresh prints.

For corporate gifting and club events, logo durability is value. If logos peel after a few hits, your “premium night experience” starts to feel disposable. Glowing shells add constraints—curvature, coatings, and surface prep matter more than buyers expect.

Your strongest de-risk move is to request a “print durability proof pack” before you lock production:

-

What surface prep is used before printing (cleaning and/or plasma).

-

An adhesion check result (your supplier’s method, documented).

-

After-hit photos that show edges and thin strokes (where failures show first).

-

Ink/material notes tied to the shell/coating system.

Why it matters: most “logo complaints” aren’t about art files—they’re about adhesion drivers and acceptance criteria that were never written down.

| Brand need | Best method | What to request | Common failure | Acceptance criteria + next step |

|---|---|---|---|---|

| 1–2 spot colors (simple logo) | Pad printing | Adhesion check + after-hit photos | Edge scuffing on thin strokes | No peeling; scuff within limit → approve |

| Full-color artwork | UV printing | After-hit photos + surface prep notes | Chipping/peel on raised ink | Ink remains intact after routine → approve or change process |

| Pantone-sensitive branding | Pad (often) | Target match on real shells | Color shift under low light | Approve in daylight + low light → lock sample |

| High-scuff event use | Pad (often) | Pad vs UV after-hit comparison | “Cheap look” after use | Choose by durability → set hit-based acceptance |

| Premium gift presentation | Pad or UV (by design) | Unlit appearance photos + packaging mock | Looks dull when unlit | Approve unlit look → confirm finish |

✔ True — Printing durability depends on surface prep and compatibility

Method labels (pad vs UV) are only the start. Adhesion drivers—surface prep, ink choice, and coating compatibility—determine whether logos survive real event hits and handling.

✘ False — “UV always looks better, so it’s always best.”

UV can be great for complex artwork, but durability varies. If you need premium appearance after use, require an adhesion check and after-hit photo proof pack on samples before mass production.

How do you ship LED golf balls DDP with batteries?

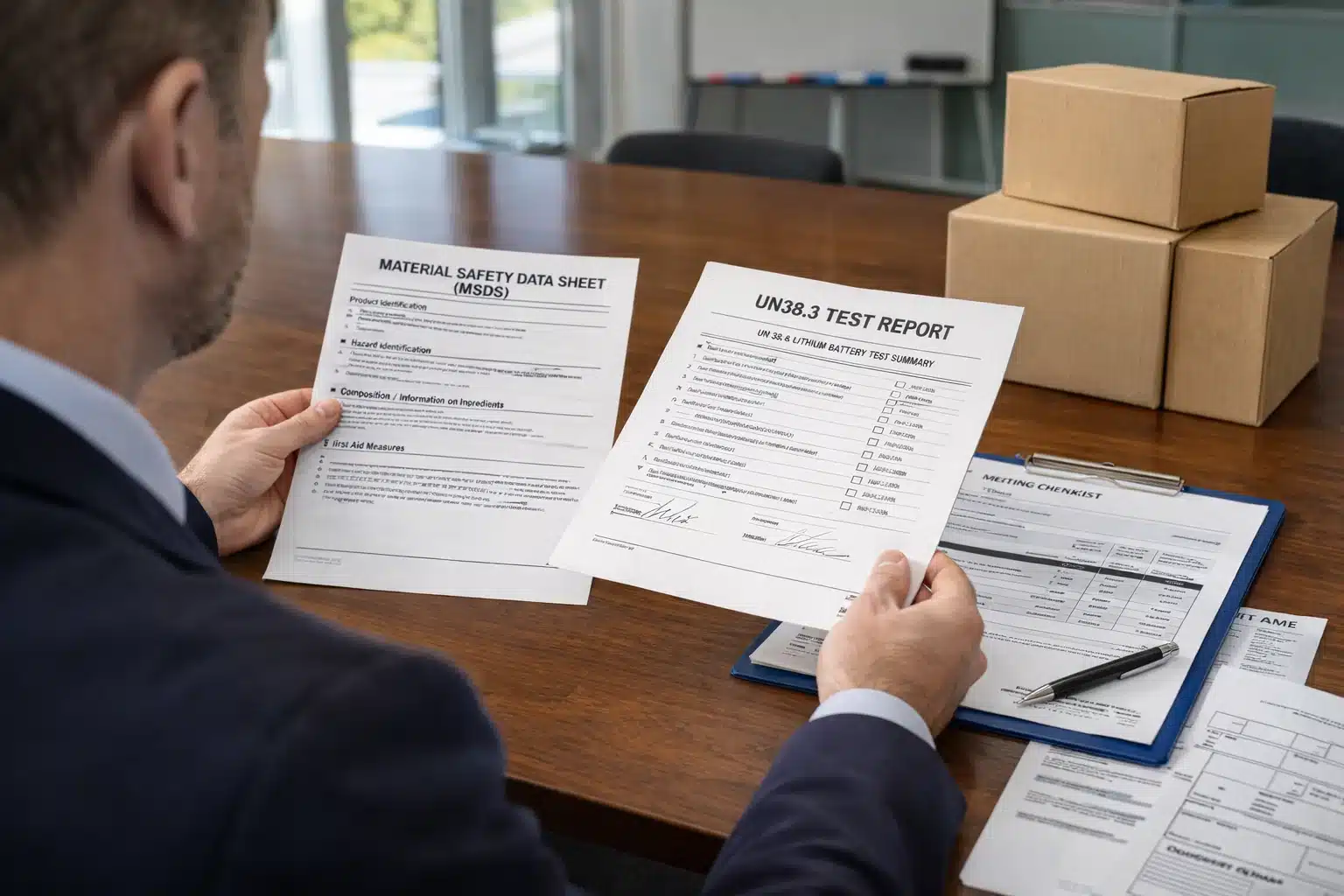

DDP is workable for battery-integrated LED golf balls when classification is correct, paperwork is complete, and a DG-capable forwarder handles the lane. Before deposit, collect the battery chemistry statement, MSDS, the required test summary (if lithium), and packaging/label photos—then have your logistics partner confirm lane acceptance in writing.

For US/EU buyers, the biggest “silent failure” risk is battery logistics: classification mistakes, missing documents, or a forwarder that can’t actually handle the lane. DDP can still be a strong option—but only if you verify documents and lane acceptance before you pay.

A simple, buyer-controlled flow (no guesswork):

-

Request documents before deposit (not after production starts).

-

Validate consistency: document wording should align with invoice/packing list statements.

-

Confirm DG capability: the forwarder must confirm the DDP lane can accept the classification.

-

Approve packaging/labels: require photos that show compliant labeling and protective packing.

-

File the evidence set internally for customs clearance and audit readiness.

5-Point QC Checklist for Bulk LED Orders (event-ready):

-

Battery file set is complete (chemistry statement + MSDS + required test summary if lithium) and lane acceptance is confirmed.

-

Sample-set activation success is logged using your routine (so variance is visible).

-

Timer behavior is verified with a stopwatch and written as “per activation.”

-

Shell surface quality is checked (seam/flash/burr/scuff) for both incoming samples and pre-shipment sampling.

-

Logo durability is approved with adhesion check results + after-hit photo evidence.

RFQ Verification Action (deliverable-focused): Provide (1) battery chemistry statement + MSDS, (2) UN38.3 test summary (if lithium), (3) shipping classification statement for the cell type ‘contained in equipment’, (4) compliant packaging/label photos, and (5) DG-capable forwarder confirmation for the DDP lane.

One more operations detail that saves bulk orders: require packaging that prevents accidental activation during transit. If cartons arrive with partially drained balls, it often looks like “DOA” but behaves like “packaging allowed activation.” Packaging photos are evidence—treat them that way.

✔ True — DDP still requires you to verify DG documents

DDP can simplify execution, but it doesn’t remove the need to collect and file the battery document set. Treat DG paperwork as a supplier-approval deliverable, not a “shipping detail” to solve later.

✘ False — “DDP means you don’t need to verify battery paperwork.”

If classification or documents don’t match the shipment declarations, delays and holds can still happen. Verify the pack before deposit and confirm lane acceptance in writing.

FAQ

Are LED golf balls tournament legal?

No—LED balls are designed for events and recreational play, not official tournament conformity. Keep claims conservative and avoid any “approved” wording.

If your client needs tournament-legal play, route them to conforming standard balls. For night events, use clear internal copy that positions LED balls as visibility equipment for entertainment and engagement.

What actually increases the risk of club damage at events?

Surface defects and rough shell condition are common drivers of worry—not just ‘firm feel.’ In bulk buying, visible shell quality is the most controllable safety lever.

Approve samples with close-up seam/flash photos. Reject visibly scuffed or rough balls. Don’t reuse damaged balls across groups—this is a simple operational rule that prevents most complaints.

What should a B2B spec sheet include for LED golf balls?

A B2B-ready spec defines construction, cover family, activation type, and the test method behind any hardness/compression claims. This prevents “we assumed” disputes across procurement, ops, and marketing.

Require “method noted” next to numeric claims. Define “per-activation timer” vs “total runtime” in writing. Include packaging requirements that prevent accidental activation and shipping scuffs.

How do we prevent logo peeling in bulk orders?

Choose pad vs UV based on logo complexity, then approve by adhesion and after-hit proofs—not by fresh prints. Durable branding needs evidence.

Request an adhesion check and after-hit photo comparison. Ask what surface prep is used before printing (cleaning/plasma). Lock acceptance criteria on samples before mass production.

How can we reduce DOA (dead on arrival) risk for 1,000+ balls?

DOA control is a process: sample-set activation checks, protective packaging, and pre-shipment evidence. You’re reducing variance, not hoping it won’t happen.

Require an activation success log on a sample set. Request packaging photos that prevent accidental activation. Ask how consistency monitoring is handled during production and what happens to rejects/rework.

What documents should we collect for DDP battery shipments?

Collect the battery chemistry statement, MSDS, required test summary (if lithium), and packaging/label photos—then validate lane acceptance with a DG-capable forwarder. This is the file set that prevents lane refusals and last-minute holds.

Ensure declarations match invoice/packing list wording. Save the document set internally so you can respond quickly if a carrier or customs checkpoint asks for confirmation.

Conclusion

For bulk LED golf balls, you don’t need blind trust—you need controllable levers: (1) shell surface condition, (2) activation/timer consistency, and (3) battery shipping paperwork. Turn each lever into proofs you collect at the sample stage, and your night event becomes repeatable instead of risky.

You might also like — How to Choose a Reliable Golf Ball Manufacturer in China?