Golf ball specs translate into on-course outcomes. Diameter ≥ 42.67 mm and weight ≤ 45.93 g govern legality; compression and core design set ball speed and feel; layers and cover material tune driver versus wedge spin; dimple geometry sets lift/drag and wind stability; roundness and symmetry preserve straight flight. Read specs as a system, validate with robot and QA data, and pick by swing speed, conditions, and intended use.

This guide is written from the vantage point of a manufacturer with 20 years in golf-ball export and 12 years in manufacturing: it shows you how to read a spec sheet, verify claims with lot-level QC and practical testing (robot curves, 50–100-yard wedge spin), choose specs by swing speed and conditions, and bake a PO-ready acceptance plan—including Initial Velocity (IV), weight/diameter, concentricity, and coating thickness in micrometers (μm)—into your contract, while avoiding traps like “more dimples = farther.”

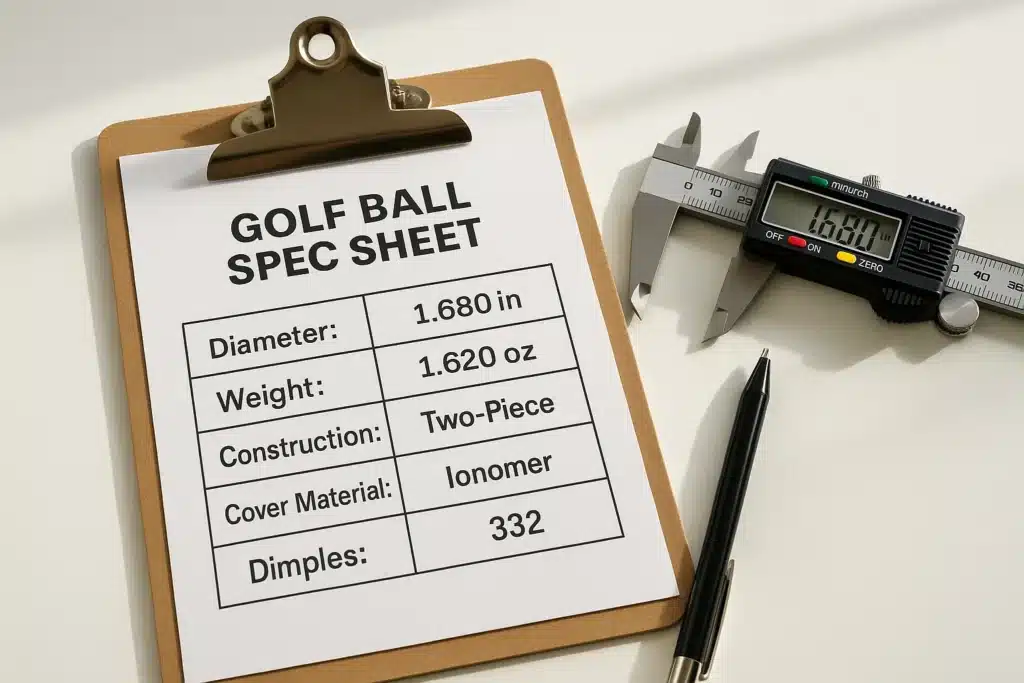

Specs at a Glance

Golf ball specifications are the levers behind distance, spin, feel, durability, and legality. You cannot rank them in isolation; they interact. The smart approach is to decode what each metric means, then read them together for your swing and course.

Master Spec Map — spec → measure → effect → trade-offs

| Spec | What it is | How it’s measured | What it affects | Typical trade-offs |

|---|---|---|---|---|

| Diameter | Ball size (must be ≥ 42.67 mm / 1.680 in) | Digital digital ball gauge | Legality; baseline stability | Cannot go smaller; tighter control reduces outliers |

| Weight | Mass (must be ≤ 45.93 g / 1.620 oz) | Calibrated scale | Inertia; wind robustness; feel | Heavier within limit feels steadier; illegal if over |

| Compression (Atti) | Whole-ball deformation under load | Compression tester | Speed potential; feel | Lower suits slower swings; higher suits faster swings |

| Shore Hardness | Layer/cover surface hardness | Durometer (C/D) | Feel; wedge spin; cut resistance | Hard ↑ durability, soft ↑ greenside grip |

| Layers (piece count) | Core + mantle(s) + cover | Spec sheet/X-ray | Driver vs wedge spin control | More layers = finer tuning and more complexity |

| Dimples | Count, depth, edge radius, layout, fidelity | Optical/templating | Lift/drag; wind behavior | Geometry/fidelity outweigh count by itself |

| COR / IV | Energy return vs standardized speed | COR rig / IV equipment | Distance ceiling and conformance | Public docs show IV more often than COR |

| OOR & Symmetry | Out-of-roundness; spin-axis neutrality | Roundness gauge / symmetry test | Straightness; dispersion | Lower OOR and neutral axis reduce “mystery curve” |

| Specific gravity | Material density of each layer | Density test | Feel, CG, MOI tuning | Buyer-side R&D/QA, rarely printed on boxes |

| Durability | Impact survival and scuff/cut | Impact rig (≈200 ft/s × 50 hits) | Service life; appearance | Chemistry and cure > sheer clearcoat thickness |

✔ True — Specs are system levers, not isolated badges

Compression without aerodynamics can balloon in wind; perfect dimples with uneven paint can still add drag. Read the sheet as a system and confirm with data, not single numbers.

✘ False — “One hero spec guarantees better performance”

You win with balanced windows: legality, speed, spin control, and clean aerodynamics together.

Compliance & Legality (USGA/R&A Essentials)

Competition legality is about thresholds and standardized tests. A conforming ball must have diameter at or above 42.67 mm, weight at or below 45.93 g, pass standardized initial velocity and overall distance programs, and demonstrate symmetry. Dimple count, color, or piece count are not regulated for conformance.

What to know (and ask for)

Request the current conforming list entry for the exact model name/ID, current initial velocity report, and proof of batch-level gauge controls. Verify symmetry testing and traceability. Treat certificates as lot-specific, not a one-time license.

Quick compliance table

| Item | Limit / requirement | Why it matters | What to request |

|---|---|---|---|

| Diameter | ≥ 42.67 mm | Smaller is illegal and can alter flight | Batch histogram and gauge calibration |

| Weight | ≤ 45.93 g | Overweight is illegal and changes inertia | 100% weight screen and lot traceability |

| Initial Velocity (IV) | Per protocol | Speed ceiling for conformance | Current IV report tied to model/lot |

| Symmetry | Must pass | Protects directional neutrality | Symmetry/roll test summary |

| Listing status | On current list | Competition eligibility | Screenshot or link plus renewal cadence |

✔ True — Conforming lists change over time

Legality is governed by the current list. Build renewal cadence into your supplier agreements and verify model names exactly as listed.

✘ False — “Once listed means always legal”

Listing is not permanent. Loss of listing means the ball is not eligible wherever USGA/R&A conformance policies apply.

Compression vs. Hardness (They’re Not the Same)

Compression is whole-ball deformation under load; it shapes impact feel and ball-speed potential. Shore hardness is a layer property that tunes surface feel, greenside spin, and cut resistance. A soft-feeling ball can still be long if the core is efficient and the aerodynamics are clean.

Compression vs. Shore — quick comparison

| Aspect | Compression (Atti, etc.) | Shore C/D hardness |

|---|---|---|

| What it measures | Whole-ball deformation | Surface/layer hardness |

| Measured by | Compression tester | Durometer |

| Drives | Speed potential and feel | Feel, wedge spin, durability |

| Player match | Lower for smoother, slower swings; higher for faster swings | Softer ↑ spin/feel; harder ↑ toughness |

| Tuning levers | Core chemistry and cure, mantle design | Cover resin choice, cure window, texture |

| Pitfalls | “Higher always longer” is a myth | Too soft can scuff; too hard can feel harsh |

How to use this

Start with your driver swing speed and typical contact quality. Bracket test two compressions (one mid, one higher or lower) against your delivery. Compare launch, spin, and dispersion on a monitor, then confirm wedge spin from 50–100 yards to ensure short-game fit.

✔ True — Compression fit is personal, not absolute

Two players with the same speed can prefer different compressions due to delivery, strike pattern, and feel priorities. Use data to pick a window, not a single magic number.

✘ False — “Softer always goes shorter”

Modern cores can pair soft feel with excellent distance, provided aerodynamics and strike quality are sound.

Layers & Construction (2-Piece vs. 3/4/5-Piece)

Layers are tuning knobs. A well-executed 2-piece ionomer ball can be outstanding for distance and value. Additional mantles expand the ability to blend driver spin, iron launch, and wedge control, but only if concentricity and tolerances are tight.

Construction comparison

| Build | Typical stack | Strengths | Watch-outs | Best for |

|---|---|---|---|---|

| 2-piece | Large core + ionomer cover | Durability, speed, price | Lower wedge spin and softer bite | Range, value, straight-flight seekers |

| 3-piece | Core + mantle + cover | Balanced launch/spin, better feel | Concentricity tolerance matters | Broad game play and fit seekers |

| 4/5-piece | Core + multiple mantles + cover | Granular control across clubs | Cost and process control demands | Fit-focused performance and shotmaking |

How to use this

Think of construction families as starting points. If you need a straight, durable ball for mixed conditions, start with a 2-piece. If you want a balanced game ball, test a 3-piece. If you’re fitting to a narrow launch/spin window, explore 4–5-piece options and demand concentricity data.

Cover Materials (Urethane vs. Ionomer vs. TPU)

Cast urethane is the go-to for greenside spin and premium feel. Ionomer often wins on durability and price while still offering strong driver distance. TPU sits between, enabling interesting colorways and feel profiles.

Cover comparison

| Cover | Feel | Driver launch/spin | Wedge spin | Durability / cut | Cost | Notes |

|---|---|---|---|---|---|---|

| Cast Urethane | Soft, premium | Neutral to low-spin, very controllable | High due to groove interaction | Good cut resistance if cured well | $$$ | Tour-leaning; cure and post-cure must be managed |

| Ionomer (Surlyn & blends) | Firmer-neutral | Often low driver spin, high speed | Moderate on wedges | Excellent scuff/cut resistance | $ | Value and distance with robustness |

| TPU | Soft–medium | Balanced | Medium–high | Good and versatile | $$ | Opens color/translucent aesthetics |

How to use this

Choose by short-game priority and wearing pattern. If you live and score with pitches and chips, urethane helps. If you chew through covers, or run corporate or range programs, ionomer is pragmatic. TPU is the flexible middle ground when look and feel are both in play.

Dimples & Aerodynamics (Count vs. Geometry)

Dimple count is a headline, not a performance guarantee. Depth, edge profile, diameter mix, layout symmetry, replication fidelity, and paint cleanliness set the lift/drag curves that govern apex height, carry distance, and wind behavior.

Dimple parameters → aero effect

| Parameter | Controls | On-course effect | Validation |

|---|---|---|---|

| Count | Coverage and flow regime | Minor alone; interacts with geometry | Ask for count plus size mix, not count alone |

| Depth | Pressure differential and lift | Peak height and carry; headwind resilience | Optical depth checks and wind-direction robot curves |

| Edge/shoulder radius | Boundary layer and drag | Stability and downrange dispersion | Microscopy and dimple fidelity audits |

| Layout/pattern | Symmetry and robustness | Crosswind stability and repeatability | Identify layout (tetrahedral/icosahedral) and tolerances |

| Replication & paint | Fidelity of the tooling and finish | Batch-to-batch consistency | Tool hygiene; paint must not clog dimples |

How to use this

Ignore marketing by count alone. Ask for drawings with depth and edge tolerances, a coating thickness map, and three wind-direction robot curves. Flight that holds shape into headwind and crosswind is worth more than an arbitrary number like “352 dimples.”

✔ True — Geometry beats simple count

Depth, edge radius, size mix, layout symmetry, and clean dimples control lift/drag. Count is a design result, not a predictor by itself.

✘ False — “More dimples automatically fly farther”

Flight depends on the entire geometry and its consistency across the batch, plus paint execution.

Speed Specs: COR & Initial Velocity (IV)

COR describes energy return in a collision. IV is the standardized conformance speed metric most buyers actually see on reports. They relate but are not interchangeable. Brands often publish IV, ball speed, and distance outcomes rather than raw COR.

COR vs. IV

| Aspect | COR | Initial Velocity (IV) |

|---|---|---|

| What it is | Energy return ratio | Standardized exit speed measure |

| Unit | Dimensionless (0–1) | m/s or ft/s per protocol |

| Used for | R&D physics and material choices | Conformance and certification |

| Public visibility | Rarely shared | Common in conformance documents |

| Buyer takeaway | Explains principles | Ask for the current IV report tied to model/lot |

How to use this

Treat IV as the conformance checkmark and a sanity check across lots. Treat COR as background physics that explains why core design and cure windows matter. For selection, your launch monitor’s ball speed and spin are the real-world synthesis.

Roundness, Symmetry & Concentricity (OOR, Spin Axis)

Straight shots wobble when geometry or mass is biased. Out-of-roundness (OOR), seam height, layer concentricity, and mass symmetry change the spin axis. The result is a “mystery fade/draw” even with a good swing. Keep these metrics controlled, and the ball flies where you aimed more often.

Straight-flight control panel

| Metric | Why it matters | Typical method | Buyer action |

|---|---|---|---|

| Concentricity | Keeps CG centered and neutral | X-ray or rotation gauge | Require concentricity charts per lot |

| OOR (Out-of-Round) | Preserves aero symmetry | Roundness gauge | Define a maximum OOR tolerance |

| Symmetry test | Flags axis bias under standard roll | Symmetry/roll test | Stop-ship on failure |

| Seam height | Affects turbulence and drag | Optical profile | Cap seam height and audit post-finish |

| Weight/Ø histograms | Reveal distribution, not just averages | 100% gates + SPC | Tie to lot IDs for traceability |

How to use this

Ask for spin-axis or polar-axis rotation data when available; it’s a practical way to quantify bias. Keep acceptance plans focused on 100% weight/diameter gates, plus regular symmetry and concentricity checks, so outliers never make it into play.

Colorways & Finish (Paint Thickness Uniformity)

Color is about visibility and brand—flight is about construction. With the same cover and coatings, colored balls should fly like their white counterparts. What matters is uniform paint thickness at the micrometer level, sound adhesion, and crisp registration for printing.

Finish control quick table

| Item | Why it matters | What to specify | How to verify |

|---|---|---|---|

| Total paint thickness | Adds mass/drag | Total μm target with limits | Micron gauge and SPC charts |

| Zone uniformity | Avoids aero asymmetry | Per-zone μm limits | Zone readings at set sampling |

| Adhesion/abrasion | Durability and print stability | Cross-hatch plus rub tests | Pass/fail criteria in PO |

| Ink–clear compatibility | Registration and clarity | Qualified ink/clear stack | Rub and solvent resistance |

| Dimple cleanliness | Aero fidelity | “No clog” criterion | Optical checks post-coating |

How to use this

If you chase durability, change paint chemistry and cure windows, not just thickness. Over-thick or uneven clear is a hidden distance tax and can bias aerodynamics.

Environment Effects (Temperature, Altitude, Humidity)

Conditions modulate how specs express themselves. Cold stiffens materials and thickens air; heat softens feel and thins air; altitude reduces drag; humidity alters groove interaction. Your spec choice should anticipate the typical environment, not only an indoor bay.

Conditions → tweak map

| Condition | What changes | What to tweak | Practical tip |

|---|---|---|---|

| Cold (<50 °F / <10 °C) | Ball stiffens; air density rises | Consider lower compression | Keep balls warm before play |

| Heat (>86 °F / >30 °C) | Ball softens; air density drops | Consider slightly firmer feel | Watch wedge spin and rollout |

| High altitude | Drag decreases; carry increases | Lower spin windows | Expect longer carry and shallower descent |

| Wet conditions | Groove friction falls | Favor higher-spin covers | Swap wet balls; keep faces dry |

| Windy days | Lift/drag sensitivity rises | Robust dimple geometries | Evaluate head/cross/tail-wind robot curves |

Selection Frameworks (By Swing Speed & Use Case)

Selecting a ball is about matching windows: speed, spin, and aerodynamics. Start with your driver speed and miss pattern, add your short-game priorities, then verify with a simple on-course test.

Swing speed → baseline picks

| Driver swing speed | Compression band | Likely cover | Expected behavior | Who benefits |

|---|---|---|---|---|

| <85 mph | Lower–mid | Ionomer or softer urethane | Easier speed, softer feel | Newer players and smooth tempos |

| 85–100 mph | Mid | Urethane or advanced ionomer | Balanced distance and greenside control | Most golfers |

| >100 mph | Mid–high (fit-driven) | Premium urethane | Spin control at speed; stable flight | Better players and fit seekers |

Use case tweaks

| Priority | Shift these specs | Why |

|---|---|---|

| Max tee distance | Lower driver spin via dimple/cover and compression fit | More carry and roll at your delivery |

| Greenside control | Softer urethane; wedge spin priority | Hop-and-stop reliability |

| Durability/value | Ionomer covers; robust finish | Practice volume and price sensitivity |

| Wind stability | Dimple geometry proven in head/crosswind | Trajectory control and dispersion consistency |

✔ True — Range balls are built for durability or reduced flight

They often remain close to conforming size/weight, but are not always managed on the USGA/R&A list. Differences stem from materials, structure, and QA targets rather than “no weight rules.”

✘ False — “Range balls have no standards”

Ask for weight/diameter screening and durability tests if your program needs consistent carry windows.

How to use this

Keep two finalists: one softer-feel option that hits your wedge spin target, and one firmer-feel option that contains driver spin. Compare dispersion and approach-stop distance, not only total yardage.

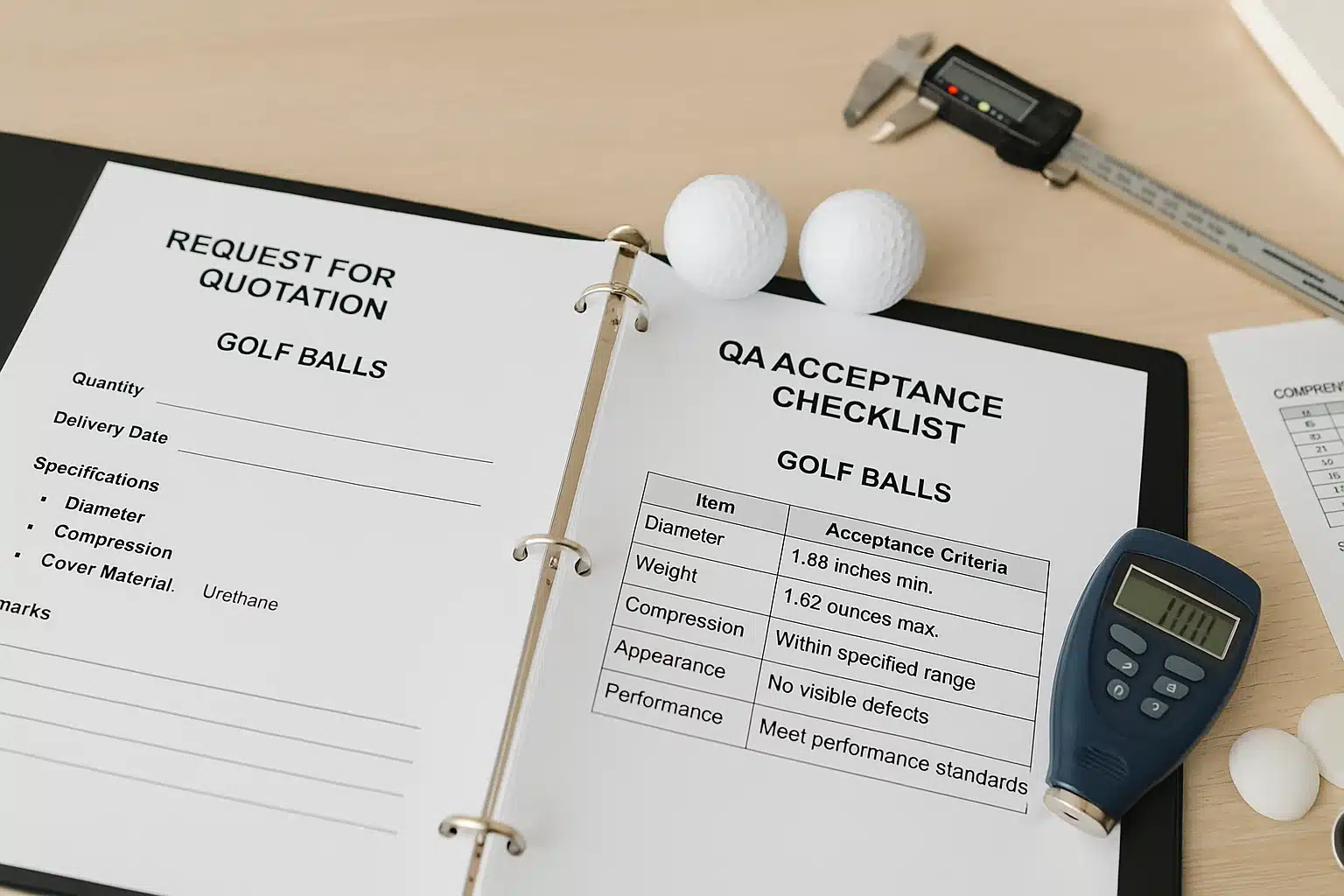

RFQ & Acceptance Checklist (What Buyers Should Demand)

Your purchase order should freeze use case (range/game/tour), structure (layers, cover, hardness), and CTQs with test methods. Tie all reports to the shipped lot, not just a model family PDF. Evaluate trends, not only single-point passes.

Acceptance plan — ready to paste into a PO

| Item | Method | Typical target/check | Notes |

|---|---|---|---|

| Weight / Diameter | Digital gauges | ≤45.93 g; ≥42.67 mm | 100% gate at pack-out |

| Compression (Atti) | Compression tester | Program window ± tolerance | Track spread and CPK |

| IV (Initial Velocity) | Standardized rig | Conformance pass | Attach current report |

| Concentricity / Symmetry | X-ray or rotation gauge | CG-neutral; seam limit | Define acceptance bands |

| Coating | Thickness (μm), adhesion, abrasion | Uniform μm; pass rub and cross-hatch | SPC trend per zone |

| Dimple fidelity | Optical/templating | Depth/edge within spec | Tool hygiene and repaint rules |

| AQL cosmetics | Visual + fixtures | Program-defined | Rework or re-grade path |

How to use this

At receiving, verify paperwork, sample compression and coating microns, and inspect dimple cleanliness. Escalate sampling if trends drift. Use histograms to see distribution, not just averages, then tie any corrective action to lot IDs.

✔ True — Test reports are lot-specific

A lab report describes a sample from one batch. Repeatability comes from capability (CPK) and live SPC, not a static PDF. Plan sampling depth and stop-ship triggers in advance.

✘ False — “A certificate means the whole shipment is fine”

Quality is a process. Require measurement evidence per lot and trend reviews by month.

Common Myths → How to Test Them (Buyer’s quick fixer)

Marketing shortcuts waste time. Replace slogans with simple, auditable tests.

| Common claim (myth) | What’s actually true | What to request from factory |

|---|---|---|

| “More dimples = better” | Geometry, layout, and replication matter more than count | Dimple drawing (depth/diameter/edge radius/layout) and coating μm map; wind-direction robot curves |

| “More layers = higher grade” | Layers are tuning; concentricity rules results | X-ray concentricity and rotation balance; symmetry/IV; weight and diameter histograms |

| “Higher compression = longer” | Fit compression to delivery; soft can still be long | Driver robot data at 95/105 mph and 50–100 yd wedge spin |

| “PU > Surlyn for distance” | Urethane wins greenside; tee distance is core plus aero | Driver and iron distance plus wedge spin comparisons |

| “Thicker clear = more durable” | Durability comes from chemistry and cure, not bulk | Coating μm distribution and adhesion/abrasion tests |

| “Once listed = always legal” | Listings update; current listing governs | Contract model and renewal cadence plus proof of listing |

| “Color changes flight” | Same construction means negligible flight change | Same shell and paint spec across colors |

| “One spec decides quality” | System behavior matters | Full CTQ matrix and acceptance methods in PO |

FAQ

Which specs matter most for distance?

Compression fit and driver spin matter most once legality is met. Ball speed comes from impact efficiency; carry depends on launch and spin; drag is managed by dimple geometry and clean paint.

Which specs matter for greenside control?

Cover and surface finish dominate wedge interaction. Urethane usually grips grooves more; microroughness and clean paint preserve spin. Keep wedge spin consistent from 50–100 yards rather than chasing peak numbers only.

Does dimple count alone predict performance?

No. Depth, edge radius, size mix, pattern symmetry, and fidelity set the lift/drag curve. Count is a design result. Validate with wind-direction robot curves and dimensioned drawings.

Are colored balls different in flight?

Not if construction and coatings are identical. Color changes visibility and appearance; performance differences should be negligible within the same model and finish stack.

How can I quickly vet a ball line?

Two steps: obtain robot curves in headwind, crosswind, and tailwind; and review X-ray/symmetry results plus weight and diameter histograms and current IV. If these pass, shortlist by feel and wedge spin fit.

Do I choose specs or a model first?

Pick a short-list by model (fit guides), then read its specs to verify they match your swing speed, spin needs, and conditions. Specs confirm fit; on-course tests confirm feel and dispersion.

Key Takeaway & Conclusion

Read specs as a system. Legality sets the floor (≥ 42.67 mm, ≤ 45.93 g); compression and core shape speed and feel; layers and cover tune driver-versus-wedge spin; dimples and finish manage lift/drag and wind; geometry/symmetry keep the axis neutral. Validate with robot curves, wedge tests, and lot-level QC (IV, weight/diameter, concentricity, paint μm). Choose the window that protects dispersion and supports scoring—so distance is repeatable, flight predictable, and feel consistent, round after round.

You might also like — Range vs Game vs Tour Golf Balls: Differences in Performance, Price, Construction, and Origin