You’ve designed a golf ball that finally feels different, and the nightmare is watching a China supplier quietly turn your IP into their next bestseller.

The five biggest IP red flags in China golf ball factories are: (1) refusal to sign a China-law NNN agreement, (2) unclear tooling and mold ownership, (3) reselling overruns or factory seconds, (4) trading companies posing as factories, and (5) weak on-site security and scrap control.

This guide shows you how to spot each red flag early, so you can screen out risky partners before they ever touch your design.

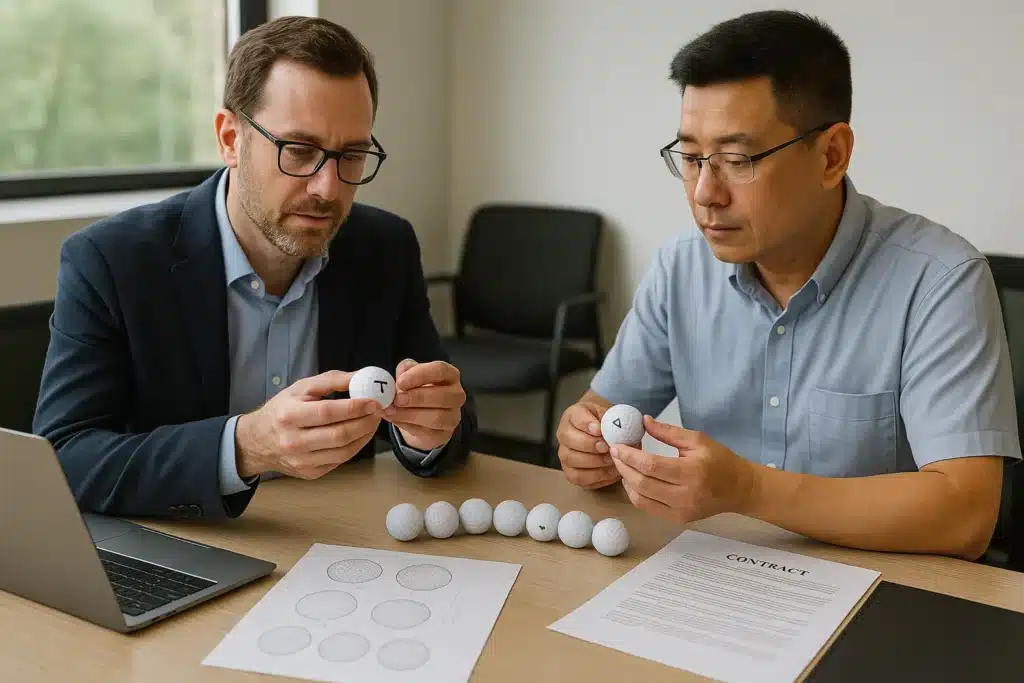

How does Red Flag #1 on NNN pushback expose your IP?

Many buyers think any NDA is enough, but in China golf ball manufacturing the wrong agreement can give a factory cover to use your dimple design, logo or formula with almost no consequence.

If a China factory refuses a China-law, bilingual NNN agreement—or pushes you to sign a generic English NDA only—that is a major IP red flag. NNN (Non-Use, Non-Disclosure, Non-Circumvention) is built to be enforced in China, while most foreign-law NDAs are hard to use there and do little to stop copycats or backdoor selling.

NNN goes beyond “don’t tell”. It says the factory may not use your drawings for other customers, may not disclose them to third parties and may not circumvent you with direct marketplace or wholesale sales. Without Chinese governing law, Chinese language and a China-based venue, you’re relying on paper that looks strict but is difficult to enforce in the place where misuse actually happens.

In golf balls, the stakes rise once your model appears on the USGA/R&A conforming list. Your construction and dimple layout are then publicly documented, so a factory that treats your NDA as “just admin” can easily launch a near-twin ball under a different logo. Serious manufacturers understand this and will discuss NNN terms; the real warning sign is when they resist the concept altogether.

✔ True — A China-specific NNN is the real starting point

For China projects, an NNN with Chinese law, Chinese text and a China venue gives you far more leverage than a one-page foreign NDA, especially when disputes involve local staff and platforms.

✘ False — “Any NDA in my drawer is fine for China”

Generic NDAs may look formal but often don’t cover non-use or non-circumvention and are hard to enforce in Chinese courts, leaving wide gaps around copycats and backdoor selling.

What should your China NNN for golf balls always include?

Use this checklist when reviewing drafts, so you can spot gaps before your CAD files or USGA samples leave your inbox.

-

Explicit non-use of drawings, specs, tooling files and lab data beyond your orders.

-

Non-disclosure to third parties, including sub-factories, without written approval.

-

Non-circumvention: no direct Amazon/marketplace or wholesale selling behind your back.

-

China governing law, bilingual text with Chinese prevailing, and a China-based venue.

-

Liquidated damages high enough to hurt if the factory breaks the rules.

-

Clear naming of IP items: “golf ball master dimple tool”, “core/mantle recipes”, “CAD files”.

| Contract type | Enforceable in China? | Covers non-use / non-circumvention? | Typical factory behaviour | Recommendation |

|---|---|---|---|---|

| Generic foreign NDA | Often weak/uncertain | Usually disclosure-only | One-page template, no localisation | High IP risk – avoid |

| China-law NNN | Drafted for local use | Yes, if properly drafted | Negotiates but accepts NNN logic | Baseline for China work |

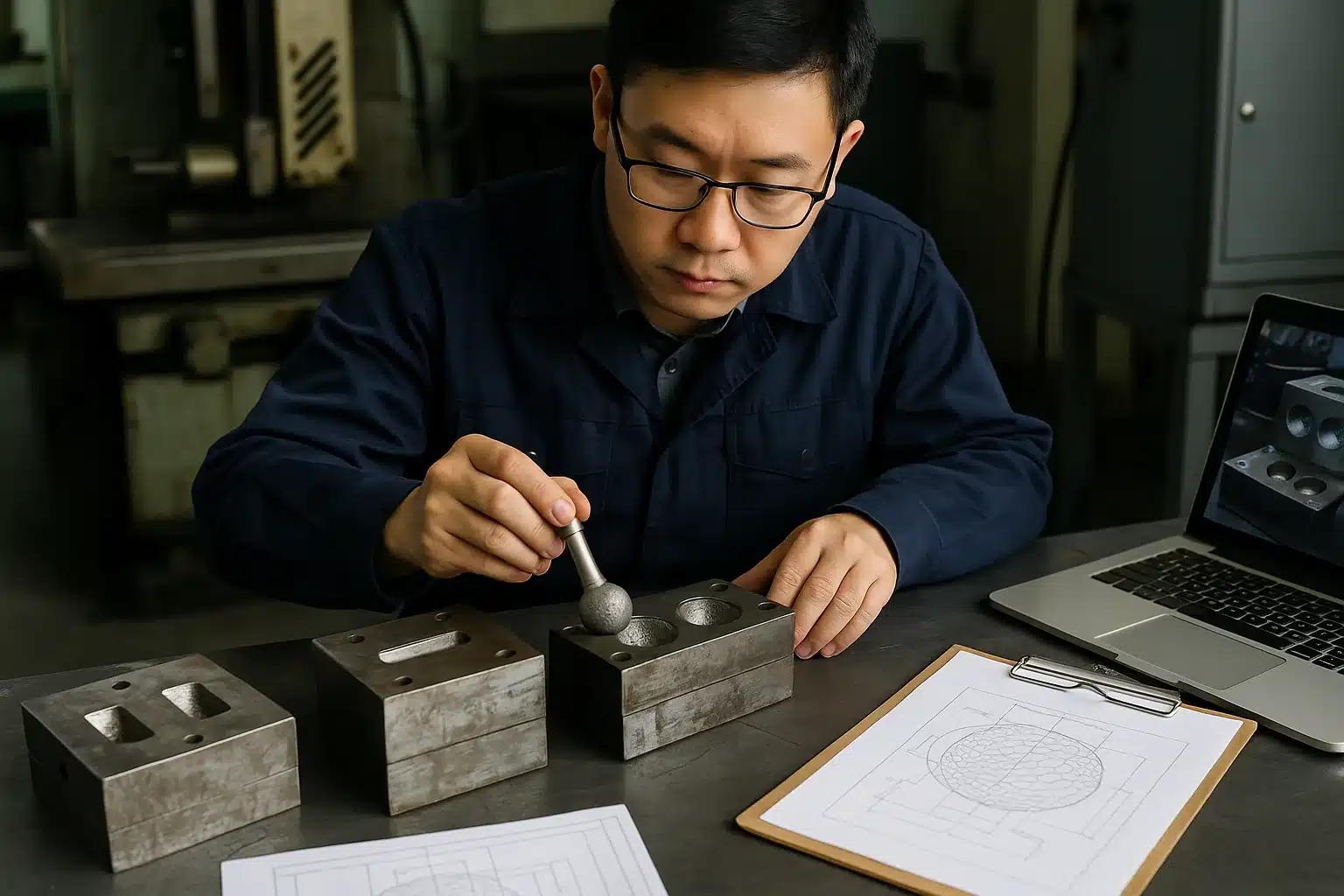

How does Red Flag #2 on tooling ownership create risk?

Golf ball tooling isn’t just hardware—it’s crystallised IP. When ownership clauses are vague, the factory holding your outer molds and dimple master can quietly monetise your design long after your first order ships.

If your China supplier’s contract is vague about who owns the golf ball molds, dimple masters and related tooling, you’re facing a serious IP red flag. Because complete tooling sets for modern multi-layer balls are expensive, factories have a strong incentive to reuse or slightly tweak them for other brands unless ownership, access and removal rights are clearly locked down in writing.

A three- or four-piece ball often needs several outer-shell molds, core molds and at least one precision master dimple tool. Combined, that’s a mid five-figure investment. Clauses like “tooling belongs to the factory but is dedicated to Client A” or silence on dimple masters while mentioning only “production tooling” create space for reuse. When you try to switch suppliers, you may discover the tools you paid for are treated as factory assets.

A protective structure flips control to you: after payment, you own the tools; the factory holds them only to produce for you; there is no reuse or copying for others without your written consent; and you can remove or scrap tooling with documented evidence. Walking away from a compromised supplier then means moving your tools, not writing off your entire IP investment.

✔ True — Tooling clauses decide who controls your physical IP

Outer molds, core molds and master dimple tools embody your design. If contracts leave ownership unclear or favour the factory, those tools can easily become a shared resource for multiple brands.

✘ False — “If I paid a tooling fee, the molds are obviously mine”

In many China contracts, tooling fees are treated as setup or service charges. Without clear ownership and removal language, you may simply have subsidised the factory’s long-term assets.

How should a golf ball tooling clause be structured?

Give your lawyer this skeleton and ask them to localise it for China, so the contract reflects how you actually expect molds and dimple masters to be controlled.

-

Ownership: after full payment, all molds, master dimple tools and printing plates belong to you.

-

Location & access: tools stay at the factory as bailee, with reasonable audit rights.

-

Reuse limits: no reuse, copying or pattern tweaks for other brands without written consent.

-

Removal/destruction: you can remove tools on notice; if scrapped, destruction is documented.

| Clause pattern | Ownership reality | Reuse risk | Switching factory friction | Recommendation |

|---|---|---|---|---|

| “Factory owns all tooling” | Factory controls tools | Very high | Extreme – molds hostage | Avoid for unique designs |

| “Client owns tooling + removal rights” | Buyer clearly in control | Low | Low – tools can be moved | Preferred for serious brand work |

Why is Red Flag #3 on overruns so dangerous for IP?

Many buyers see overruns as harmless: “at least they don’t waste product.” In reality, a factory that sells other brands’ overruns tells you exactly how it will treat your logo, your molds and your launch timing.

If a prospective golf ball factory is already selling other brands’ overruns, misprints or “factory seconds” under its own store—especially on Alibaba, AliExpress or local B2C apps—that is a direct IP red flag. The same channels they use today for other brands’ surplus are the ones they will use tomorrow for your ball once it gains momentum.

“Overruns” are units produced beyond the PO quantity; “seconds” are balls with logo or cosmetic flaws. IP-safe factories either destroy them, rework them under strict rules or deal with them under written brand approval. A risky plant lists them as “OEM tour overrun”, blurs logos, or sells “no-logo tour balls” whose specs copy famous models line by line.

This risk peaks when your ball starts appearing on Kickstarter, YouTube or Amazon. If your supplier already treats surplus as side inventory, early runs of your hero ball can leak into discount channels before you have a chance to occupy your price and positioning.

How do overruns and backdoor selling typically show up online?

Use this quick check before you even request a quote, so you see how the supplier behaves with other people’s IP.

-

Search for “OEM Tour overrun”, “no-logo tour performance” or “from famous brand factory”.

-

Watch for blurred logos or photos that hide branding but clearly show dimple patterns.

-

Compare specs with big-name models: construction, compression and cover that track too closely.

-

Ask how they handle misprints and overruns—and insist on “destroyed, not resold” in writing.

| Factory policy | What happens to overruns/seconds | Brand damage risk | Recommendation |

|---|---|---|---|

| Resell with blurred or hidden logos | Leak through side channels | Very high | Walk away |

| Sell as unbranded practice balls | Repacked and sold as generic | Medium–high | Only with tight written controls |

| Documented destruction | Shredded or crushed with proof | Low | Strong positive IP signal |

Why are trading-company-only suppliers an IP red flag?

Sourcing through a trading company can feel comfortable: better English, faster quotes, friendly WeChat. The hidden cost is that you often lose visibility into which real factory holds your molds, formulations and dimple masters.

If the “factory” you’re talking to is in fact only a trading company, your IP risk increases sharply. Trading companies rarely control workshop access, scrap destruction or data sharing. In practice, your drawings and ball specs may be forwarded to multiple factories, making it very hard to control who ends up copying your design or who is bound by your contracts.

Golf balls are sensitive because small differences in layer thickness, compression or dimple geometry can create a “clone” ball. A trader that sources from several anonymous plants may blast your full spec to whichever offers the lowest price that month, while your NNN and tooling clauses bind only the middleman. The real mold holders then sit outside any enforceable agreement.

A safer model is transparency: use a trader for communication or logistics if you like, but know exactly which factory runs your ball and sign NNN and tooling language directly with that manufacturer. The entity that stores your molds and handles overruns must be clearly named and contractually accountable.

✔ True — Your contracts must reach the real producer

A trader can help with sourcing and communication, but only the workshop that holds your molds and sees your full specs can actually leak or protect your IP. That party must sign your NNN and tooling terms.

✘ False — “If the trader signs, all partner factories are automatically bound”

Unless the specific factories are identified and agree to your terms, they may have no legal obligation to your brand. This gap is where many copycat stories quietly begin.

How can you tell a real golf ball factory from a trader?

Run these checks early so you can separate true manufacturers from middlemen before sharing detailed specs.

-

Product focus: factories focus on balls; traders push broad catalogues.

-

Location: factories sit in known golf-ball clusters; traders in generic office buildings.

-

Process visibility: real molding/coating footage instead of only showrooms or stock photos.

-

Technical depth: engineers, not just sales reps, answer questions on compression and testing.

-

Paper trail: contracts and invoices that clearly name the manufacturing entity, not just the trader.

| Signal | Real factory behaviour | Trading-only behaviour | IP impact | Decision hint |

|---|---|---|---|---|

| Product focus | Narrow, ball-focused range | Very broad, many categories | More/fewer leak points | Prefer focused suppliers |

| Workshop access | Live production shown on video | Only showroom or stock photos | Harder/easier to audit IP | Push for real-plant proof |

Why is weak on-site security a serious IP red flag?

Even with strong contracts, weak workshop security can leak your IP in minutes. A single uncontrolled visit, unlocked scrap bin or smartphone video of your dimple master can feed a competitor’s tooling shop.

If a golf ball factory allows unrestricted visitors, open photography on the shop floor, or leaves test balls and scrap lying around, you’re looking at a major IP red flag. IP-safe plants treat custom molds, dimple masters and unreleased balls like assets—controlling access, banning filming and tightly managing how defective product is stored, labelled and destroyed.

Security starts with basics: visitor sign-in, badges, escorted tours and restricted access to molding and custom-printing areas. In an IP-aware shop, phones are limited around tooling; unreleased balls are not stacked in open cartons near doors; and misprints don’t sit in open bins where anyone can grab samples. For golf balls, a handful of cut or intact balls is enough to reverse-engineer your structure and dimple pattern.

If the factory cannot show simple controls—locked tooling cabinets, labelled scrap, basic shredders or crushers—it is unlikely they will suddenly tighten up once your ball appears on the conforming list or starts trending online.

What should a secure custom golf ball workshop look like?

Use this mental picture when reviewing site photos or video tours, and assume reality is rarely better than what they chose to show.

-

Segregated custom lines with controlled entry, not free-for-all shop floors.

-

Locked cages or cabinets for master dimple tools and sensitive jigs.

-

Clear no-photo signage near molding and printing, enforced by staff.

-

Labelled scrap bins away from visitor routes, ideally separated by project.

-

Visible destruction methods for misprints and rejects, with simple logs.

| Practice | Observed behaviour | Leakage likelihood | IP stakes (golf-specific) | Action |

|---|---|---|---|---|

| Visitor control | Badges, logs, escorted visits | Low | Fewer chances to capture tooling | Accept |

| Photo policy | No phones near tooling | Low | Harder to copy dimple masters | Positive signal |

| Scrap handling | Locked bins, regular destruction | Low–medium | Rejects don’t fuel reverse-engineering | Require as minimum |

How can you protect your golf ball brand in China?

Spotting red flags is only half the job. To truly keep your IP safe, you need a simple, staged playbook—from pre-China filings to supplier choice, contracts and ongoing checks.

To protect your golf ball IP in China, think in stages: first, secure trademarks and key design or utility rights where they matter most; second, shortlist only factories that pass basic IP hygiene checks; third, lock in China-law NNN and tooling clauses before sharing full specs; and finally, monitor security, overruns and online markets over the life of the project.

Stage one is groundwork. Before sending CAD files, talk with counsel about which elements to register—brand names, logos, distinctive dimple layouts or multi-layer structures—and which jurisdictions to prioritise, including China if budgets allow.

Stage two is supplier screening. Turn the five red flags into a shortlist filter: NNN attitude, tooling wording, overrun behaviour, trader vs factory structure and basic security practices. Many risky suppliers can be removed without ever sending detailed drawings.

Stage three is contracting and sampling. Insist on signed NNN and tooling clauses before full disclosure; share information in stages; and keep early samples small while you test how the factory handles data, QC reports and misprints.

Stage four is monitoring. Once your ball is on the conforming list or gaining traction online, schedule periodic video checks of production and scrap handling, quick searches for suspicious lookalikes and simple annual contract reviews.

What does an “IP-safe” golf ball factory look like in practice?

A low-risk manufacturer behaves differently from high-risk suppliers, so you can recognise them before committing to tooling or big orders.

-

Offers China-law NNNs by default and accepts reasonable edits.

-

Explains tooling ownership clearly and accepts your right to remove molds.

-

Commits in writing to destroy overruns and misprints, and can show proof.

-

Runs in-house tests on weight, diameter, compression, hardness and COR, and shares data.

-

Controls workshop access and phone use and can show security practices on video.

-

Owns the factory rather than hiding behind layers of traders.

| Stage | Key actions | Main risk reduced | Owner | Quick check |

|---|---|---|---|---|

| Pre-China filings | Register key trademarks/designs | Brand hijack, bad-faith filings | Buyer | “What have we filed, and where?” |

| Supplier screening | Apply 5-red-flag checklist | High-risk suppliers in funnel | Buyer | “Why did this factory pass shortlisting?” |

| Contracting | Sign NNN + tooling terms before full disclosure | Spec leakage too early | Shared | “Do contracts match our risk level?” |

| Monitoring | Video checks, platform scans, contract reviews | Drift into risky behaviour | Shared | “When did we last verify IP controls?” |

FAQ

Can I patent a golf ball dimple pattern or only the overall ball?

You can often protect both the overall ball and specific dimple patterns using a mix of design and utility rights, but the realistic scope and value depend on novelty, prior art and how aggressively you plan to enforce.

In practice, golf ball IP portfolios blend trademarks, design registrations and patents on core structure, layer bonding and aerodynamics. Dimple layouts can be patentable if they are genuinely new and non-obvious versus existing patterns, but proving that requires proper prior-art searches and good drafting. Most brands therefore prioritise a few key markets and their most distinctive technical features. Work with IP counsel experienced in sports equipment and ask which parts of your design are worth protecting, given your budget and launch plan.

Who legally owns the molds if I pay for tooling in China?

Paying for golf ball tooling in China does not automatically make you the legal owner. Ownership of molds, dimple masters and printing plates depends entirely on contract wording, not on who wrote the cheque.

Default contracts often describe tooling payments as “contributions” or “setup fees” but still say tools belong to the factory, or mention only “production tooling” and ignore master dimple tools. In those cases, the factory can keep and reuse tools if you switch suppliers. If you want control, the agreement must clearly state that you own tooling once paid, that the factory holds it only to produce for you, that there is no reuse or copying without written consent and that you can remove or scrap tools with documented evidence.

Is a Chinese factory without USGA listing automatically low quality?

No. A factory without balls on the USGA/R&A conforming list is not automatically low quality; the list mainly shows that specific models were submitted, passed and kept on it by paying ongoing fees.

USGA listing is valuable when you target formal tournament play or want the credibility of independent rules checks. But maintaining multiple models on the list costs money and admin time, so some OEM-focused or value-driven factories don’t see it as essential, especially when they mostly produce under private labels. To judge quality, look at their ability to hit tight tolerances on weight and diameter, control compression windows, measure hardness and COR and maintain consistent cosmetics at scale.

Should I work with a trading company first to “test the waters”?

Trading companies can help with language and logistics, but they also add IP risk if you don’t know which factory makes your ball and don’t have NNN and tooling clauses in place with that manufacturer as well as the trader.

For first-time buyers, traders can feel easier: they coordinate multiple suppliers and handle communication. The danger is assuming their contract alone protects you. If they rotate factories or broadcast your spec to several plants to chase price, your IP is exposed far beyond what your paperwork covers. A safer compromise is to let a trader coordinate, but insist on meeting the real factory, doing video tours of production lines and having NNN and tooling terms signed by both entities.

How early should I involve a China factory if I plan a Kickstarter or big launch?

Involve a China factory early enough to refine design and tooling, but not so early—or so loosely—that full specs and branding circulate before basic IP protections and supplier controls are in place.

Crowdfunding and social campaigns create perfect copycat conditions: you prove demand and pricing in public while filings and contracts might still be incomplete. If several factories already hold detailed drawings, compression targets and branding, some will be tempted to move faster than you. A better approach is to lock core IP filings, choose at least one trusted factory and sign NNN and tooling clauses before showing the full picture, while limiting what you share with backup options.

What basic lab tests should a serious golf ball factory be able to run in-house?

A serious golf ball manufacturer should at least be able to test weight, diameter, compression, cover hardness, coefficient of restitution (COR) and basic durability in-house, and ideally measure concentricity as well.

Weight and diameter checks confirm basic conformity; compression and hardness show whether core and cover recipes are under control; COR and durability tests reveal how the ball will feel and last in real play. Concentricity checks—via X-ray or cut-and-measure routines—are especially important for multi-layer balls, where off-centre cores cause flight and feel issues. When you ask about lab capability, listen for specific equipment and test frequencies, not just “we test”.

Conclusion

IP risk with China golf ball factories is not random; it follows patterns. Once you recognise those patterns, you can design your sourcing process to avoid most disasters before they start.

The five red flags in this guide—NNN pushback, vague tooling ownership, overrun selling, trading-only suppliers and weak on-site security—are practical filters, not legal theory. If even two of them show up in one factory, treat it as a warning and move on. There are China manufacturers who respect IP and will prove it in their contracts, processes and data.

You can absolutely build a successful, IP-safe golf ball line in China. Treat IP as a front-loaded discipline: file what matters, screen factories hard, lock contracts before sharing full specs and then verify what happens on the shop floor. Turn this article into a checklist for RFQs, supplier calls and audits, and work only with partners prepared to sign solid NNNs, clarify tooling, prove their QC and show real security on video—before they ever touch your dimple pattern.

You might also like — Private Label Golf Balls Economics: Tour-Quality on a Budget