Brand teams worry that their Pantone-perfect logo on paper will turn into three different reds once printed on spherical, dimpled golf balls. Without a clear color-control workflow, each batch can drift further from the original standard.

To ensure perfect Pantone color matching on custom golf ball orders, use a full color-management workflow: combine digital proofing, Pantone-based ink systems, calibrated spectrophotometers, controlled pad-printing parameters, curing and abrasion testing, and batch-by-batch ΔE checks so every shipment stays visually on-brand.

The rest of this guide walks you through each step of that workflow, from understanding why golf balls are hard to print to the exact checks you should insist on before shipment.

Why Is Pantone-Accurate Printing on Golf Balls So Difficult?

Many buyers assume that if a Pantone code is specified, the logo will automatically match across all batches. In reality, spherical geometry, dimples, varying cover materials and complex coating stacks make golf balls one of the trickiest substrates for consistent Pantone color.

Pantone matching on golf balls is hard because you’re printing tiny artwork onto a curved, dimpled surface that already carries primers, basecoats and clear coats. Each layer, plus differences between Surlyn and urethane covers, affects how the ink wets, anchors and visually appears under light.

On a small, dimpled sphere, the pad never touches every point with identical pressure and angle. Pad hardness, machine pressure and cliché depth all influence local ink film thickness, so the same logo can look slightly darker or lighter from pole to equator if the setup is not tightly controlled. That means even perfectly mixed ink can show visible variation within one print.

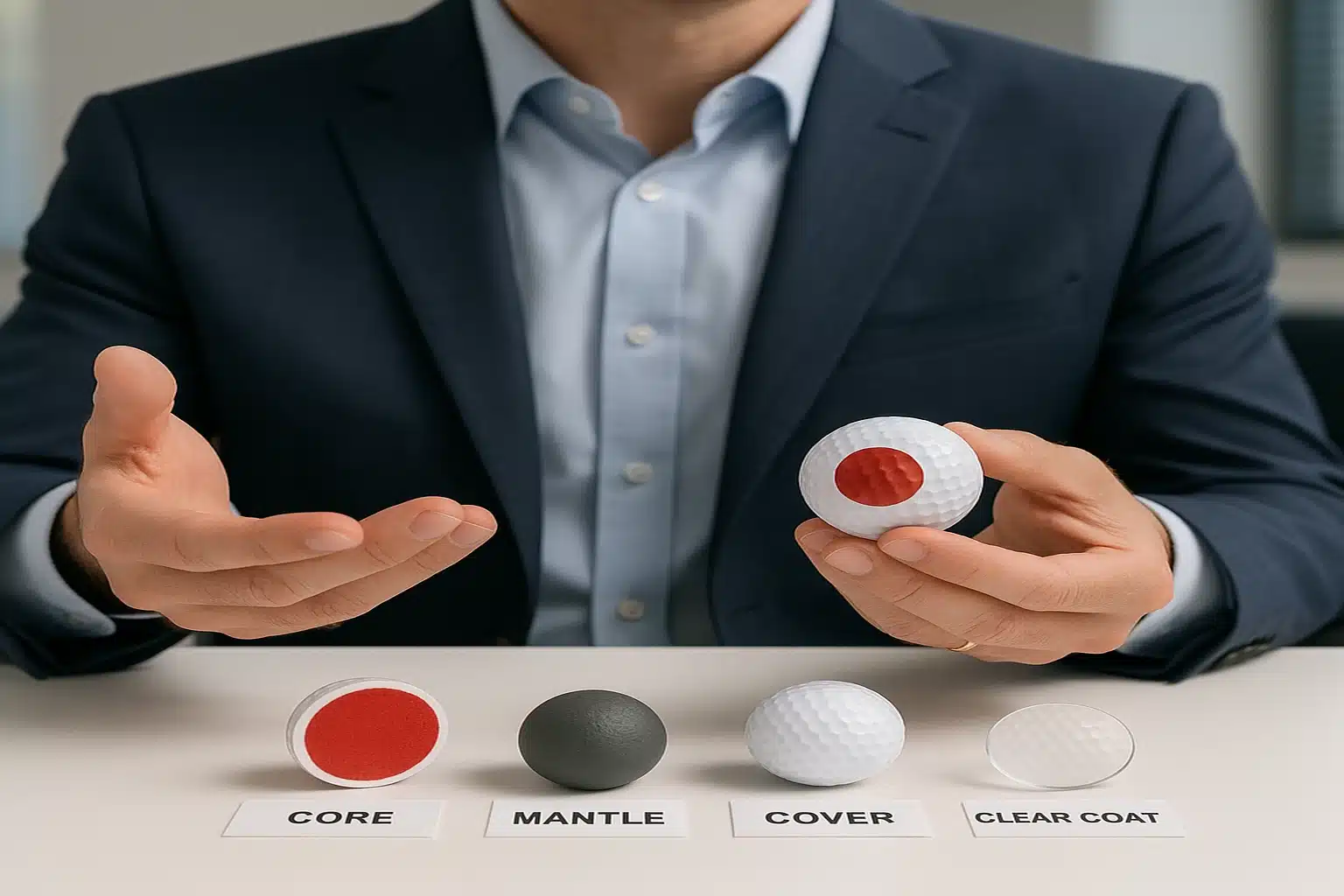

The coating stack adds another layer of complexity. A typical ball goes from core to mantle to cover, then through primer, color coat, clear topcoat and finally logo ink. Each layer has its own gloss and surface energy, and each construction type (2-piece Surlyn, 3-piece Surlyn, 3-piece urethane) presents a different “white” and surface texture. Change coating thickness or gloss, and perceived color shifts—even if the pigment does not. This is why ΔE measurement under controlled conditions is more reliable than “looks okay” under office light.

How Do Golf Ball Materials Influence Logo Color Behavior?

For logo behavior, cover material is your starting point. Surlyn/ionomer covers are harder and extremely durable, with coating systems optimized for scuff and abrasion resistance. Once properly cleaned and primed, they give robust adhesion and stable color even after repeated washing, which is why they dominate promo and range balls.

TPU injection-molded urethane covers, common in Chinese 3-piece “urethane” OEM balls, deliver a softer feel and higher spin but are more sensitive to curing and cleaning chemistry. Over- or under-cure can change ink flexibility and gloss; some detergents can slowly haze certain urethane clears, nudging perceived color over time. Tour-level cast urethane is more stable but less common in China due to cost. The practical takeaway: each cover family needs tuned ink, primer and cure conditions, and serious suppliers will validate Pantone color on every ball type you plan to use.

What Is the 5-Step Pantone Matching Protocol for Golf Balls?

Telling a factory “please match Pantone 186C” is not a process; it’s a wish. To make Pantone matching repeatable, you need a written, 5-step protocol that covers digital proofing, ink formulation, machine setup, curing and final ΔE measurement on actual balls.

A robust Pantone matching protocol for golf balls runs in five steps: verify Pantone codes in a digital proof, mix ink from Pantone-based formulas, calibrate with a spectrophotometer, optimize pad-printing on test balls with documented settings, and finally release mass production only if on-ball ΔE00 values fall within an agreed tolerance window.

In pre-press, the factory sends a vector proof that locks in Pantone codes, logo size, position and whether the mark overprints or knocks out white. This step eliminates wrong colors and low-resolution files before any ink is mixed. In the ink room, technicians use Pantone-oriented pad-printing ink systems to mix your color, print drawdowns and measure them against the swatch with a calibrated spectrophotometer. Only inks within the ΔE00 target move to press.

On-press, the pad-printing team tunes pad hardness, cliché depth, viscosity and pressure, then runs 20–50 test balls. These are inspected for edge sharpness, registration and coverage, and representative logos are measured directly on the curved surface. After curing, simple tape or rub checks confirm adhesion. Only once test prints look clean and stay within tolerance should the line be released for mass production, followed by final ΔE00 checks on finished balls before shipment.

✔ True — Pantone spot colors should be the master reference

On golf balls, ink is mixed from Pantone-oriented recipes and verified with spectrophotometers against Pantone chips or swatch cards, not against CMYK or RGB conversions. This keeps production anchored to a single, physical standard.

✘ False — “We can just send CMYK or RGB values and expect a match”

CMYK and RGB are useful for screen and print previews, but they do not define the ink formula on a dimpled, coated ball. Insist that your Pantone code, not a converted value, is written into the technical specification.

| Step | Key Action | Main Tools | Go/No-Go Criterion | Buyer Recommendation |

|---|---|---|---|---|

| 1 | Approve digital proof | Vector artwork, Pantone guide | Pantone codes, logo size/position confirmed | Do not allow ink mixing before this is approved in writing |

| 2 | Mix and verify ink | Pantone formula book, spectrophotometer | Drawdown ΔE00 within target/tolerance | Ask for drawdown photos and sample ΔE00 numbers for critical colors |

| 3 | Optimize pad-printing on test balls | Pad printer, viscosity cup, magnifier | Test balls visually clean with stable coverage | Request photos of test prints on actual balls, not just flat panels |

| 4 | Cure and test adhesion | UV/heat curing unit, tape/rub tests | No visible ink removal or smearing after tests | Clarify minimum tape/rub performance in your spec |

| 5 | Run lot and verify ΔE00 on finished balls | Spectrophotometer, reference ball | Lot average/max ΔE00 within agreed window | Require a simple color report per lot, especially for repeat orders |

How Do the Five Steps Work in Practice?

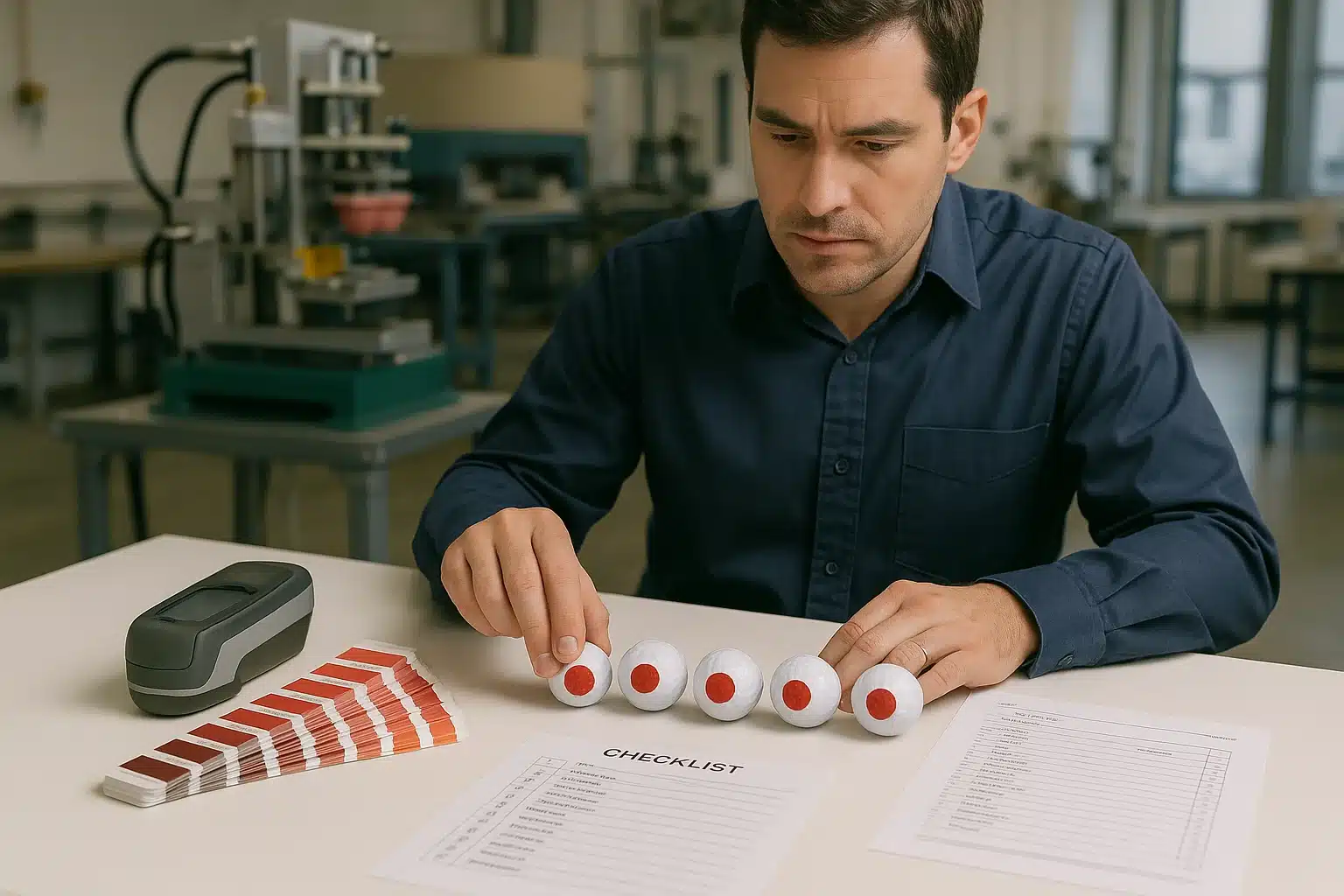

Operationally, the protocol becomes a simple checklist. Step 1 removes artwork mistakes; Step 2 ensures your ink is built from Pantone formulas and passes objective ΔE00 limits; Step 3 locks in pad-printing parameters on real balls; Step 4 confirms curing and adhesion through quick tape or rub tests; Step 5 verifies that every lot statistically stays within your agreed color tolerance. As long as these gates are written into RFQs and POs, “spectrophotometer color verification” and “color tolerance ΔE” turn into measurable requirements instead of vague promises.

How Do Color Accuracy and Consistency Differ on Golf Balls?

It’s possible to approve a perfect Pantone sample and still receive future batches that feel “off” in color. The hidden difference is between one-time accuracy to the standard and ongoing consistency between lots, which must be controlled by ΔE tolerances and process discipline.

Color accuracy means how close your golf ball logo is to the Pantone standard at approval; color consistency means how tightly future batches cluster around that approved target. Both can be managed using Delta E (ΔE00) tolerances and documented spectrophotometer checks on each production lot.

In color science, Delta E (ΔE) expresses the distance between two colors in a device-independent space such as CIELAB. A ΔE around 1.0 is often cited as the smallest difference a trained observer can see; values below 1.0 are usually indistinguishable under standard viewing. For practical work, many suppliers adopt ΔE00 ranges such as ≤1.0 (invisible), 1–2 (slight), 2–3.5 (noticeable but acceptable) and >3.5 (obvious color shift).

Accuracy is about your master: how close the approved ball is to the Pantone swatch. Consistency is about every later lot: how ΔE00 values stay clustered around that master over time. Good OEMs track both using spectrophotometer data and retained reference balls, so ink batch changes, cover material tweaks or coating adjustments do not gradually shift brand colors without anyone noticing.

| ΔE00 Range | Visual Perception | Typical Use Case | Recommended Action | Note |

|---|---|---|---|---|

| ≤1.0 | Essentially invisible | Master approval samples | Aim here for brand-critical logo approvals | Close to Pantone swatch-card internal tolerance |

| 1.0–2.0 | Slight, experts may notice | Premium urethane balls, key promo runs | Acceptable for production lots if controlled | Safe even when balls are compared side by side |

| 2.0–3.5 | Noticeable but commercially usable | Bulk promo or range balls | Accept if price-sensitive; tighten for hero SKUs | Communicate that small variations are normal |

| >3.5 | Obvious color shift | Out-of-spec or test-only | Investigate, hold or rework lot | High risk of visible mismatch in a dozen box |

✔ True — Different ΔE formulas exist, but ΔE00 is best for perception

Legacy formulas like ΔE76 and ΔE94 still appear in older equipment, yet ΔE00 aligns better with how humans see color shifts, especially in saturated logo reds, blues and greens.

✘ False — “Any ΔE value is fine as long as it’s small”

If your spec does not state which ΔE formula applies, buyer and factory may measure the same balls and get different numbers. Always specify “ΔE00” explicitly in documents.

How Should You Set Practical ΔE Tolerances for OEM Orders?

A simple framework is to separate “ideal” from “maximum” values. For premium urethane balls or flagship Pantone colors, you might target ΔE00 ≤1.5 and cap at ΔE00 ≤2.0 versus the approved standard. For bulk promo Surlyn balls, a cap around 3.0 is typically acceptable if the price point is aggressive and balls from different campaigns are unlikely to be mixed.

Tie these numbers to your sampling and AQL plan: define how many balls are measured per lot, which ΔE00 value triggers rework or discount, and how color nonconformities are categorized in inspection reports. Super-tight tolerances such as 0.5 ΔE are realistic on Pantone swatches, not on dimpled, coated golf balls. The goal is to define a window that keeps your brand safe while recognizing the physical limits of the substrate.

Which Printing Methods Give Durable Golf Ball Logos?

A logo that matches Pantone perfectly but rubs off after a few rounds is worse than useless. To specify the right process, you need to understand how pad printing compares with screen and UV digital printing, and which durability tests prove that your chosen method will survive cleaning, club impact and ball pickers.

For golf balls, pad printing remains the industry standard because a soft silicone pad conforms into dimples and transfers fine logo details with stable ink film thickness. Combined with robust curing and abrasion testing based on ASTM D5264 and D4060, pad-printed logos can deliver both Pantone fidelity and real-world durability.

Pad printing was built for small 3D objects. The silicone pad flexes into dimples and around curvature, maintaining even pressure and consistent ink film thickness. That makes it ideal for Pantone spot colors, small text and multi-color logos on balls. Screen printing excels on flat or lightly curved panels but struggles to maintain mesh contact on deep dimples, leading to distortion and uneven ink build. UV/digital systems can work with special fixtures and profiling but are far less standardized for golf balls.

Durability is validated with abrasion-style tests. ASTM D5264 (Sutherland rub) measures how printed surfaces survive repeated rubbing with a standardized pad under defined load; ASTM D4060 (Taber abrasion) assesses coating wear using rotating wheels. For balls, the same logic applies: set a load, define dry and wet cycles, then check for visible damage and measure any ΔE00 shift. Well-tuned pad-printing ink and cure systems should comfortably withstand these tests.

| Aspect | Pad Printing | Screen Printing | UV/Digital | Recommendation |

|---|---|---|---|---|

| Best substrate | Small, irregular 3D shapes (e.g., balls) | Flat or slightly curved panels | Selected 3D objects with fixtures | Default choice for most custom golf balls |

| Curved/dimpled fit | Excellent pad conformity into dimples | Poor on deep dimples | Highly system-dependent | Use screen/UV only with proven ball-specific processes |

| Pantone accuracy | Strong with spot-color ink systems | Harder to control film on spheres | Good in theory; needs profiling | Choose pad print for Pantone-critical logos |

| Durability | High with proper cure/top coats | Moderate; edge wear risk | Depends on ink and cure | Confirm via rub/abrasion tests |

| MOQ/flexibility | Efficient for medium-to-large runs | Great for large flat runs | Sometimes attractive for very small MOQs | Let MOQ and artwork drive exceptions |

How Can You Objectively Measure Logo Durability?

A practical lab-style protocol can be built around ASTM D5264 principles. Fix the ball in a cradle, rub the logo area with a felt or cloth pad under a defined load, and count dry and wet cycles separately. For wet tests, soak the pad in a neutral detergent similar to common club-cleaning liquids. After testing, inspect for film breakthrough, smearing, gloss loss and color transfer onto the cloth.

To connect durability with color, measure ΔE00 on the logo again and compare with an untested reference ball. A typical requirement is “no visible ink removal” and a post-test ΔE00 shift of ≤3.0, which keeps the logo visually on-brand even after harsh cleaning. This compresses years of towel rubs and club washers into a controlled, repeatable procedure that buyers can ask suppliers to document.

How Does Golfara Guarantee Pantone Color on Golf Balls?

Many factories say they can “match Pantone,” but only a few can show you spectrophotometer reports, lab test data and USGA-grade QA routines. Golfara’s approach goes beyond checking a Pantone chip under a desk lamp and formalizes color control in the same way elite balls manage weight, compression and symmetry.

At Golfara, Pantone matching is managed like any other critical performance spec. We use Pantone-oriented ink systems, calibrated spectrophotometers, pad-printing SOPs, adhesion and abrasion tests, and lot-based ΔE00 reporting to keep logo colors within tight tolerances across Surlyn and urethane ball families.

On the color side, Pantone swatches define our targets. Ink systems are chosen for Pantone compatibility; drawdowns and on-ball test prints are measured with spectrophotometers using ΔE00. For brand-critical colors, we target ΔE00 ≤1.0 against the master and cap lots at ≤2.0; anything outside this range triggers corrective action before shipment. Surlyn and urethane families receive tailored primers and cure schedules, so “color consistency in OEM golf balls” is maintained even across different constructions.

✔ True — USGA/R&A listing is about rules, not printing quality

Conforming status focuses on parameters like weight, size, symmetry and distance. A ball can be USGA-grade in construction and consistency even if the factory does not pay annual listing fees for every model.

✘ False — “If a ball is not on the USGA list, its quality must be poor”

For most logo programs, internal QA capability and color management matter more than current list status. Tournament-focused projects are the main cases where formal conformity is essential.

What Documentation Can You Expect from Golfara on Each Lot?

For color-critical work, Golfara can provide a straightforward document package with each shipment. Typically this includes a spectrophotometer summary showing average and maximum ΔE00 values per logo color against the approved standard ball, a brief description of the sampling plan and an AQL-based report for printing defects like smears, misregistration and missing logos.

For projects that require stronger traceability, we can retain physical samples and archive detailed data such as Lab* values, ink batch numbers and notes on any process changes. Buyers are encouraged to mirror this in their POs: specify Pantone codes, ΔE00 limits, test methods and acceptance rules so “custom golf ball logo printing QC” is driven by shared numbers rather than subjective impressions under random lighting.

FAQ

What is a realistic color tolerance for golf ball logo printing?

Most OEM projects specify Delta E 2000 (ΔE00) tolerances between 1.0 and 3.0 for golf ball logos, with tighter bands for brand-critical colors and slightly wider bands for bulk promo runs.

For premium urethane balls or hero campaigns, a target around ΔE00 ≤1.5 and a hard cap of ≤2.0 gives tight visual control without making production unmanageable. For high-volume promos or range balls, tolerances up to about 3.0 are typically acceptable, especially when balls from different runs are unlikely to be mixed. The more often balls from multiple lots will sit side by side, the tighter your tolerance should be.

How do I specify AQL for logo printing defects on golf balls?

For logo printing on golf balls, many buyers adopt AQL levels between 0.65 and 2.5 for critical defects such as missing logos or major misregistration, and slightly looser levels for minor blemishes that do not affect brand perception.

Start by defining defect categories. Critical defects include missing logos, wrong color versions or extreme misalignment that misrepresents the brand; these get the tightest AQL. Major defects might be heavy smears, double images or obvious voids inside the logo. Minor defects are small specks outside the logo or tiny flaws visible only at close distance.

How can I quickly test if a golf ball logo is durable enough?

A simple field check is to rub the logo firmly with a white cloth, both dry and slightly damp with mild detergent, for 20–30 strokes and check for visible ink removal, smearing or color transfer.

This is a small-scale cousin of ASTM D5264 rub tests and works well in offices or pro shops without formal labs. Test several balls from different boxes, applying similar pressure each time. After dry and wet rubbing, the cloth should show minimal or no ink, and the logo should not show film breakthrough or heavy gloss loss. If you see obvious color transfer or the mark becomes patchy or smeared, treat it as a red flag for poor curing or weak adhesion.

Is pad printing always better than UV or screen printing for golf balls?

For most spherical, dimpled golf balls, pad printing is the safest choice because the silicone pad conforms to the surface and maintains logo sharpness and color density; UV or screen methods are usually reserved for specific setups or flat accessories.

Pad printing has the longest track record in OEM golf balls and is well supported by Pantone-oriented ink systems, making it the default for brand-critical logos. Screen printing is efficient and economical on flat panels and textiles but tends to distort artwork and color density on dimpled spheres. UV and digital options can work, yet they demand carefully engineered fixtures, profiling and validation before risk-sensitive brands should rely on them.

Will logo color behave differently on Surlyn vs urethane golf balls?

Yes, the same Pantone ink can look slightly different on Surlyn and urethane balls because cover hardness, surface energy and clear coat stacks change how the ink film levels and reflects light.

Surlyn covers are harder and very robust under cleaning, while urethane covers are softer and often paired with different primers and topcoats to balance feel and durability. These variations change gloss and micro-texture, which shifts the way light interacts with the pigment layer. The ΔE00 difference may be small but can still be visible when balls are mixed.

Do I need USGA or R&A certified balls for my logo project?

You only need USGA/R&A-listed balls if your project targets tournaments or customers who specifically demand conforming models; for most promo or corporate programs, color quality and durability matter far more than formal rules compliance.

USGA/R&A conformity addresses size, weight, symmetry and distance, not printing or color. Many OEM factories can build tour-grade constructions yet skip annual listing for some models because certification is expensive and not every project needs it. For corporate gifts, charity days, ranges or casual retail lines, non-listed balls can still fully satisfy performance and quality expectations as long as QA is strong.

How can I tell if a Chinese golf ball supplier is truly professional on QA?

Professional golf ball factories combine fast, logical communication with visible production focus, in-house QC labs, clear test equipment lists and real spectrophotometer or compression reports instead of generic marketing promises.

Screen suppliers by specialization and location: plants that focus on golf balls and sit in established Chinese golf-ball clusters tend to have better process maturity. Ask for genuine photos or videos of molding, coating, pad-printing and testing areas, along with a basic equipment list that includes compression testers, hardness meters and, ideally, spectrophotometers.

Conclusion

Pantone matching on golf balls is not magic; it’s a sequence of decisions that either tighten or loosen your color window. Once you see how geometry, materials, printing and QA link together, you can turn vague expectations into a clear, auditable specification.

To keep logo colors on-brand, treat Pantone matching as a managed process: define the Pantone standard, specify ΔE00 tolerances, choose pad printing and proven ink systems, insist on durability tests and require lot-based spectrophotometer reports. When your OEM follows these steps, color disputes disappear and repeat orders become painless.

You might also like — How Long Does It Take to Manufacture Golf Balls?