China-based OEMs making 2-piece Surlyn (ionomer) golf balls include Ningbo Golfara, Shenzhen Xinjintian, Hangzhou Grasbird, and Xiamen MLG. All offer private-label programs for practice and USGA-conforming play balls.

Top 4 Manufacturers

| Factory | City | 2-Piece Surlyn capability (practice/play) | Typical MOQ | Lead-time notes | Common dimple families |

|---|---|---|---|---|---|

| Ningbo Golfara | Ningbo | 2-piece Surlyn line; 3/4-piece catalog available; private-label | ~1,000 pcs | Sampling 7–15 days (existing tools/colors); mass 20–35 days after artwork lock | 332/342/352 |

| Shenzhen Xinjintian | Shenzhen | Broad 2/3/4-piece range including practice SKUs; OEM/ODM | 2000–5,000 | Same baseline as above; bulk practice builds fastest | 332/342/352 |

| Hangzhou Grasbird | Hangzhou | 2-piece Surlyn parameters published; spec-driven builds | ~5,000 | FOB Ningbo common; spec-tight builds toward upper lead-time | 332/342/352 |

| Xiamen MLG | Xiamen | 2/3/4-piece with USGA-conforming 2-piece offers | ~2000 | Good for retail packs; gift boxes add time | 332/342/352 |

Lead time & MOQ (one-line benchmark): Sampling 7–15 days (existing tools/colors), mass 20–35 days after artwork lock; MOQs ~1,000–5,000 depending on finish, color count, and packaging.

Reference price bands (FOB, illustrative): Practice $0.32–0.45/ball; Play (USGA-conforming) $0.39–0.60/ball — paint/prints/packaging add incremental cost.

Practice vs Play — what’s the difference in a 2-piece Surlyn ball?

Both are two-piece Surlyn; the intent and tolerances differ. Practice skews hard compression (often 90+) and thicker shells for durability. Play targets 70–90 compression, tighter weight/diameter control, and stable flight within USGA/R&A limits.

✔ True — 2-piece Surlyn can be either a practice ball or a USGA/R&A-conforming play ball

Both share the same two-layer build (solid core + ionomer cover). The difference is intent and tolerance: practice builds prioritize durability and cost; play builds prioritize performance and rule compliance.

✘ False — “2-piece Surlyn automatically means practice ball”

What separates them isn’t layer count but tuning: compression target (practice often 90+, play 70–90), tighter weight/diameter dispersion (e.g., ≤±0.3 g / ≤±0.15 mm), thinner cover for spin control, and packaging (bulk vs sleeves/dozens).

-

Practice priorities: scuff resistance, cost, bulk/mesh-bag packing, wider dispersion accepted.

-

Play priorities: roundness, shell-thickness uniformity, tighter dispersion, sleeve/dozens/gift boxes.

Rules that anchor your spec (USGA/R&A)

Anchor to weight ≤45.93 g and diameter ≥42.67 mm, then set internal caps for weight/diameter dispersion, compression, initial velocity/COR, roundness, and paint adhesion.

-

Recommended caps (per lot): weight ≤±0.3 g, diameter ≤±0.15 mm, compression target ±3.

-

Carton transparency: print dimple-tool IDs, production date, batch traceability.

Manufacturing process & QC — what to control first?

Standard flow: core compounding/molding → Surlyn cover forming (compression or injection) → dimple tool finish → deflash/polish → primer/top-coat/UV → pad print → cure → 100% visual. Quality hinges on shell uniformity, tool care, and disciplined paint.

-

Compression vs injection: either meets spec if tools are maintained; verify shell-thickness at defined points (e.g., ±0.05 mm target).

-

Pre-paint gates: weight/diameter, roundness, initial velocity/COR. Paint must not be a crutch for tolerance.

-

Data to request: dimple-tool photos/IDs, 24-ball distributions, compression scatter, shell-thickness maps, paint grams added, retained-sample policy (6–12 months).

Lead times, MOQs & pricing

Sampling 7–15 days (existing tools/colors); mass 20–35 days after artwork lock. MOQs ~100–5,000 by finish and color count. Price drivers: ionomer grade & shell thickness, paint stack, print colors, and packaging.

-

Reference ranges (FOB, illustrative)

-

Practice builds: $0.32–0.45/ball

-

Play (USGA-conforming): $0.39–0.60/ball

-

-

Payment & terms: T/T common; FOB Ningbo/Xiamen/Shanghai (sea) or EXW (air/express). Request carton-level QA photos pre-balance.

✔ True — Model landed cost per dozen including CBM realities

Freight is volume-driven. Tubes/blisters inflate CBM and can outweigh material savings; fold-flat sleeves/dozens compress volume for air/express. Compare lanes and lock the format only after total landed-cost simulation.

✘ False — “Lowest EXW unit price always wins”

Ignoring dimensional weight creates overruns. Volume—not grams—usually decides real cost.

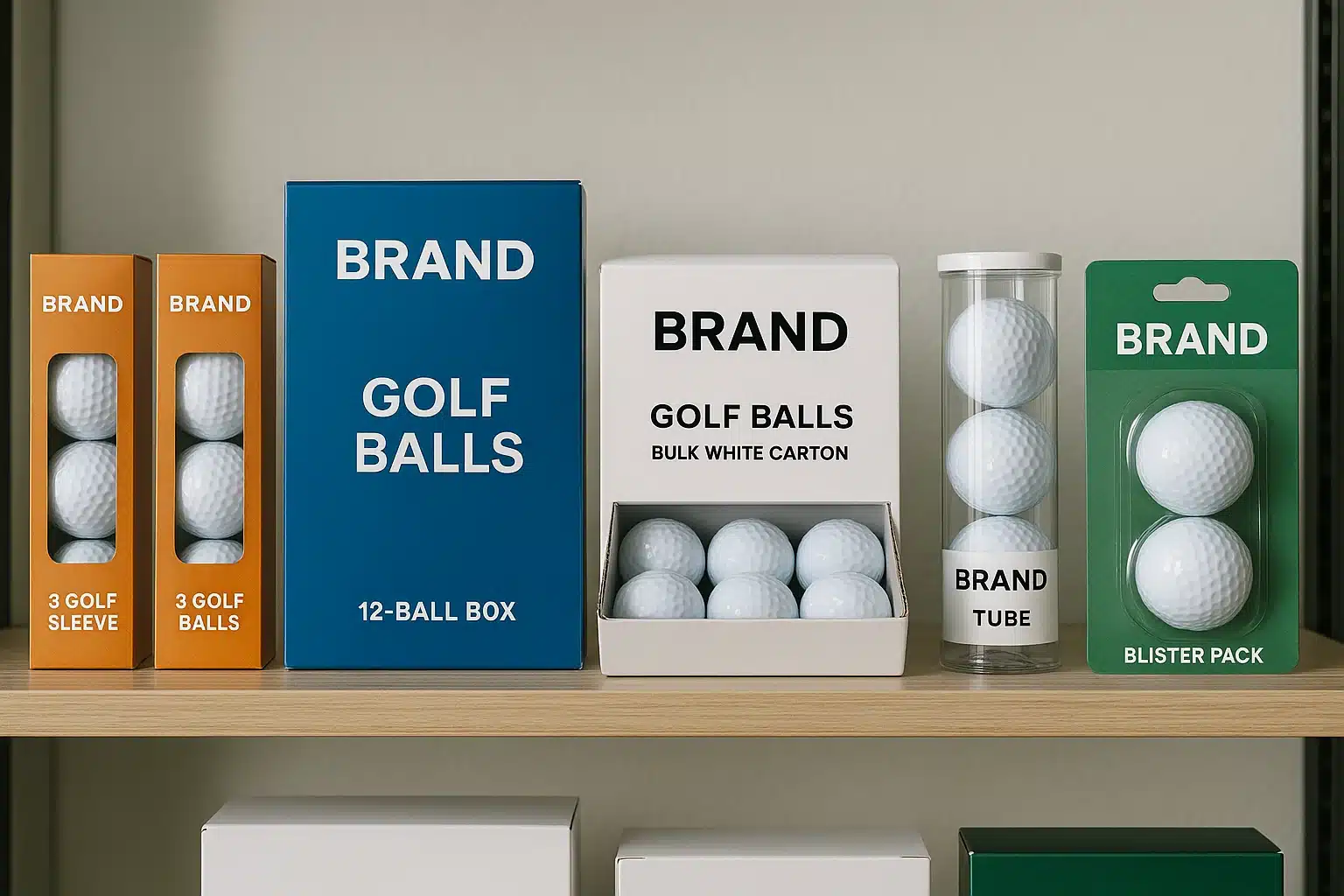

Packaging & CBM (air vs sea)

| Format | Typical inner | Outer-carton loading (dozens) | Approx CBM/dozen (illustrative) | Notes |

|---|---|---|---|---|

| 3-ball sleeves + 12-ball box | 4 sleeves | 12 | 0.012–0.014 | Best for air/express; fold-flat before assembly |

| Bulk white box (12) | 1 | 15–18 | 0.011–0.013 | Tightest packout; low labor |

| Tube (3) × 4 | 4 tubes | 8–10 | 0.014–0.017 | Round voids waste space; strong retail impact |

| Blister (2/3) | mixed | 8–12 | 0.015–0.018 | Highest dimensional weight; extra protection needed |

FAQs

Are 2-piece Surlyn balls legal for tournaments?

Yes—if they meet weight ≤45.93 g and diameter ≥42.67 mm and pass performance lines. Many house-brand “distance” balls are conforming two-piece ionomer builds.

What compression fits ~90 mph swing speed?

80–85 is a safe middle. Softer 70–80 helps in cold climates; harder 88–90 adds firmness but may feel harsh.

Surlyn vs urethane: when to upgrade?

Urethane adds short-game spin/softness at higher cost and care. For high-volume B2B, 2-piece Surlyn usually wins on durability, printability, and replenishment speed.

Can I get matte neon without scuff issues?

Yes—test on your exact paint stack. Run UV aging, detergent rubs, and 200–500 machine strikes; confirm logo edge crispness.

You might also like — How to Source OEM Golf Balls from China: Specs, MOQ & Lead Time