OEM Golf Ball Packaging — At a Glance (9 types)

| Type | Cost Tier | Typical MOQ (per SKU) | CBM Impact | Best Channel | Notes |

|---|---|---|---|---|---|

| 3-Ball Sleeve | Low | 500–1,000 | Low (foldable) | Retail/Distributor | 4C print, fast assembly |

| Dozen Box | Low–Mid | 500–1,000 | Low (foldable) | Retail/E-com | Stacks well, big branding |

| PET/PVC Tube (3) | Mid | 2,000–3,000 | High | Promo/Visual | Scuff risk; rPET preferred |

| Blister / 12-Ball Tray | Mid | 3,000+ / 5,000+ | High | Warehouse/Club | Tamper-evident, tooling |

| Nylon Mesh Bag | Lowest | 500–1,000 | Low | Range/Promo | Minimal branding |

| OPP/PE Bag | Lowest | Stock-based | Low | Inner pack/E-com | Not display-ready |

| Rigid Box + EVA | Mid–High | 300–1,000 | Mid–High | Club/VIP | Premium finishes |

| Wooden Box + EVA | High | 200–500 | High | Limited/Collectible | Species & fumigation |

| PU Leather Box + EVA | High | 500–1,000 | High | Membership/Corporate | VOC/odor control |

If you sell into retail, choose Sleeve + Dozen; for the lowest landed cost, pick Nylon/OPP; for tough warehouse displays, go Blister/Tray; for visual promos, use PET tubes; for premium gifting, upgrade to Rigid, PU leather, or Wooden boxes with EVA. Always model CBM and drop-test readiness.

What are the best packaging options for OEM golf balls?

The best OEM golf ball packaging balances display, protection, and logistics. Use 4×Sleeve + Dozen for retail standards, Nylon/OPP for bulk speed, Blister/Tray for anti-tamper durability, PET tubes for visibility, and Rigid/PU/Wooden boxes with EVA for premium gifting. Confirm MOQ, tooling, CBM, and drop tests before PO.

-

Standard retail set: 4×3-ball sleeves + 1 dozen box inside a master carton

-

Bulk/promo: Nylon mesh or OPP/PE (lowest unit cost, fastest handling)

-

Hard-channel/warehouse: 3-ball Blister or 12-ball Tray + Card (anti-tamper, impact-resistant)

-

Premium gifts: Rigid gift box + EVA, PU leather box + EVA, Wooden box + EVA

-

E-commerce: Dozen + ship-ready mailer (ISTA 1A/2A), snug cavities to prevent rattling

-

Shipping by air? Prefer foldable paper boxes (lower CBM)

✔ True — Model landed cost per dozen including CBM and air-lane realities

Freight is volume-driven. Tubes/blisters inflate CBM and can outweigh material savings; fold-flat sleeves/dozens compress volume for air/express. Compare sea vs. air and lock the format only after total landed-cost simulation.

✘ False — “Lowest EXW unit price wins regardless of freight”

Ignoring CBM and dimensional weight creates budget overruns. Volume, not grams, usually decides your real cost.

Which OEM golf ball packaging types work best for mass OEM runs?

For OEM scale, prioritize formats with stable MOQs, predictable printing, and efficient assembly. Core winners are 3-ball Sleeves, Dozen boxes, PET tubes, Blister/Tray, Nylon mesh, OPP/PE bags, plus Rigid/PU/Wooden gift boxes with EVA. Choose based on channel, CBM, and the brand experience you need.

3-Ball Paper Sleeve (350–400gsm)

Use 3-ball sleeves for low cost, fast printing, and retail-ready merchandising; pair with a dozen box for transport safety and standard shelf presentation across regions.

Best for: Retail & distributor packs (4×Sleeves + Dozen)

Pros: Low paper cost; strong shelf presence; full-color print; fast assembly

Limits: Moderate moisture/compression resistance; needs outer dozen for transport

Typical MOQ (per SKU): 500–1,000 sleeves

QC: Paper gsm, ΔE≤2.0, glue 180° peel, snug ball fit

✔ True — Lock color with ΔE≤2.0 and substrate-specific targets

Approve swatches on the actual board + laminate. Freeze ink sets, plate/anilox, and curing windows. Maintain viscosity and temperature logs so sleeves remain consistent across reruns and plants.

✘ False — “If the PDF looks right on screen, print will match”

Paper shade, coating, and press conditions shift color. Without controlled targets, wall displays reveal variation fast.

Dozen Box (holds 4×Sleeves)

Choose a dozen box to maximize branding panels and stackability; it is the retail outer for sleeves and the most familiar selling unit for omnichannel programs.

Best for: All retail/distribution and e-commerce

Pros: Stacks well; wide branding area; protects sleeves

Limits: Requires master carton optimization; adds box-making step

Typical MOQ (per SKU): 500–1,000 boxes

QC: ECT/BCT, sleeve fit, lamination, die-cut accuracy

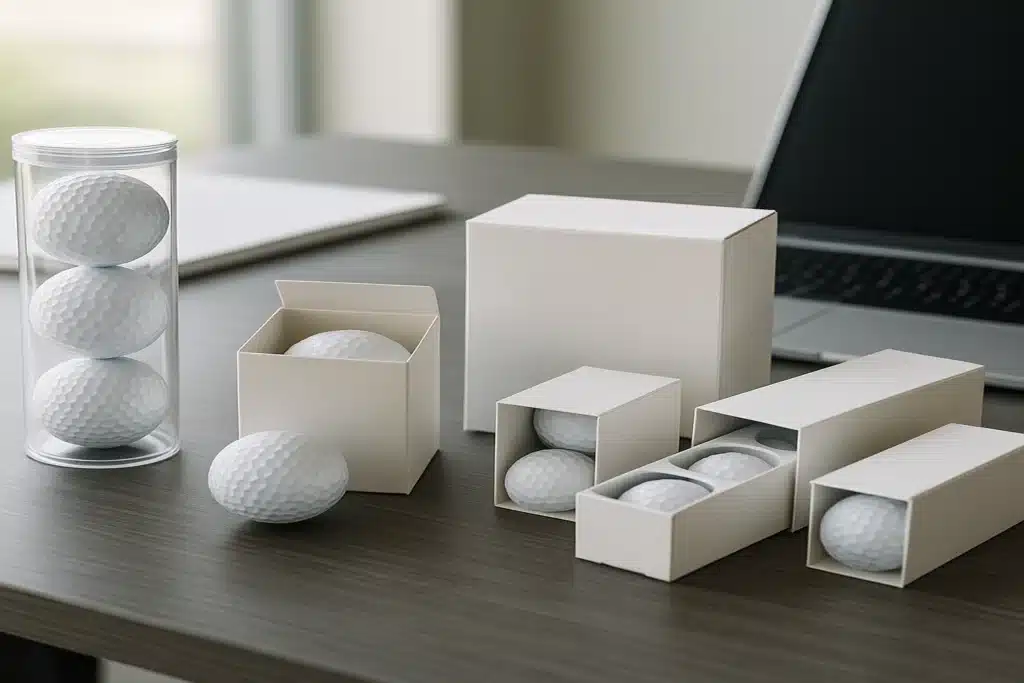

PET/PVC Clear Tube (3-ball)

Pick PET/PVC tubes when visual impact matters; they show the balls clearly and resist crush, but scuff easily and raise CBM versus foldable paper.

Best for: Promo bundles, visual merchandising, giftable entry sets

Pros: Product visible; decent crush resistance

Limits: Scratches easily; PVC sustainability concerns; higher CBM than foldable paper

Typical MOQ (per SKU): 2,000–3,000 sets

QC: Wall thickness, haze/scratch tests, print adhesion

✔ True — Specify PET with anti-scuff and adhesion tests

Use rPET where possible, and test screen/foil adhesion plus haze/scratch after simulated shelf rub. PVC may face perception/compliance headwinds; document pass criteria before mass runs.

✘ False — “Clear tubes are automatically premium and durable”

Unprotected tubes scuff easily; poor adhesion looks worn on shelf. Add coatings and QC gates or expect returns.

Blister Pack (3-ball) / 12-Ball Tray + Card

Use 3-ball blisters or 12-ball trays for tamper evidence and rugged, display-ready packs in warehouse clubs; plan for tooling, heat-seal control, and higher CBM.

Best for: Warehouse/club stores and high-touch retail

Pros: Anti-tamper; impact-resistant; display-ready

Limits: Tooling cost/time; higher assembly labor; larger CBM

Typical MOQ (per SKU): 3-ball blister 3,000+; 12-ball tray 5,000+

QC: Heat-seal strength, tray fit, scratch resistance

✔ True — Tamper evidence depends on seal strength, dwell, and peel behavior

Define heat-seal targets and validate on the actual line. Audit seal integrity during packing (not only lab). Set acceptance windows for peel force and visual defects at tear zones/hang holes.

✘ False — “Any clamshell is automatically tamper-evident”

Weak or inconsistent seals invite pilferage. Tamper evidence is engineered, not implied.

Nylon Mesh Bag (12/24/50 balls, drawstring)

Choose nylon mesh for the lowest unit cost and fastest bulk handling at ranges and promos, accepting limited branding and value perception.

Best for: Driving ranges, promotion, wholesale bulk

Pros: Cheapest; fast loading/unloading; warehouse-friendly

Limits: Limited print area; low-end perception

Typical MOQ (per SKU): 500–1,000 bags

QC: Stitching/tear strength, logo fastness (200 rubs), drawstring durability

OPP/PE Self-Seal Bag (single/multi)

Deploy OPP/PE self-seal bags as ultra-economical inner packs or quick promos; they add moisture protection but are not display-ready on their own.

Best for: Bulk inner packs, giveaways, e-com kitting

Pros: Lowest material cost; quick packout; moisture barrier

Limits: Minimal brand impact; not display-ready alone

Typical MOQ (per SKU): Stock-based by converter

QC: Seal integrity; opening/closing after 10 cycles

Rigid Gift Box (Lift-off/Magnetic) + EVA

Use rigid magnetic or lift-off boxes with EVA when perceived value and unboxing matter; they support accessories and premium finishes while adding CBM and takt time.

Best for: Clubs, corporate gifts, tournaments VIP

Pros: Premium feel; accessory-friendly; rich finishes

Limits: Higher unit cost; larger CBM; slower takt

Typical MOQ (per SKU): 300–1,000 sets

QC: Board strength, wrap quality, EVA density/fit, odor/TVOC

✔ True — Specify EVA density, hardness, and pocket tolerances

Freeze density/hardness ranges, pocket depth/diameter, and top-clearance so balls don’t top the lid or rattle. Approve first-article fit before cutting mass foam sheets.

✘ False — “Any common EVA will work for all boxes”

Wrong density or sloppy tolerances crush logos, loosen fit, or crack wraps in transit.

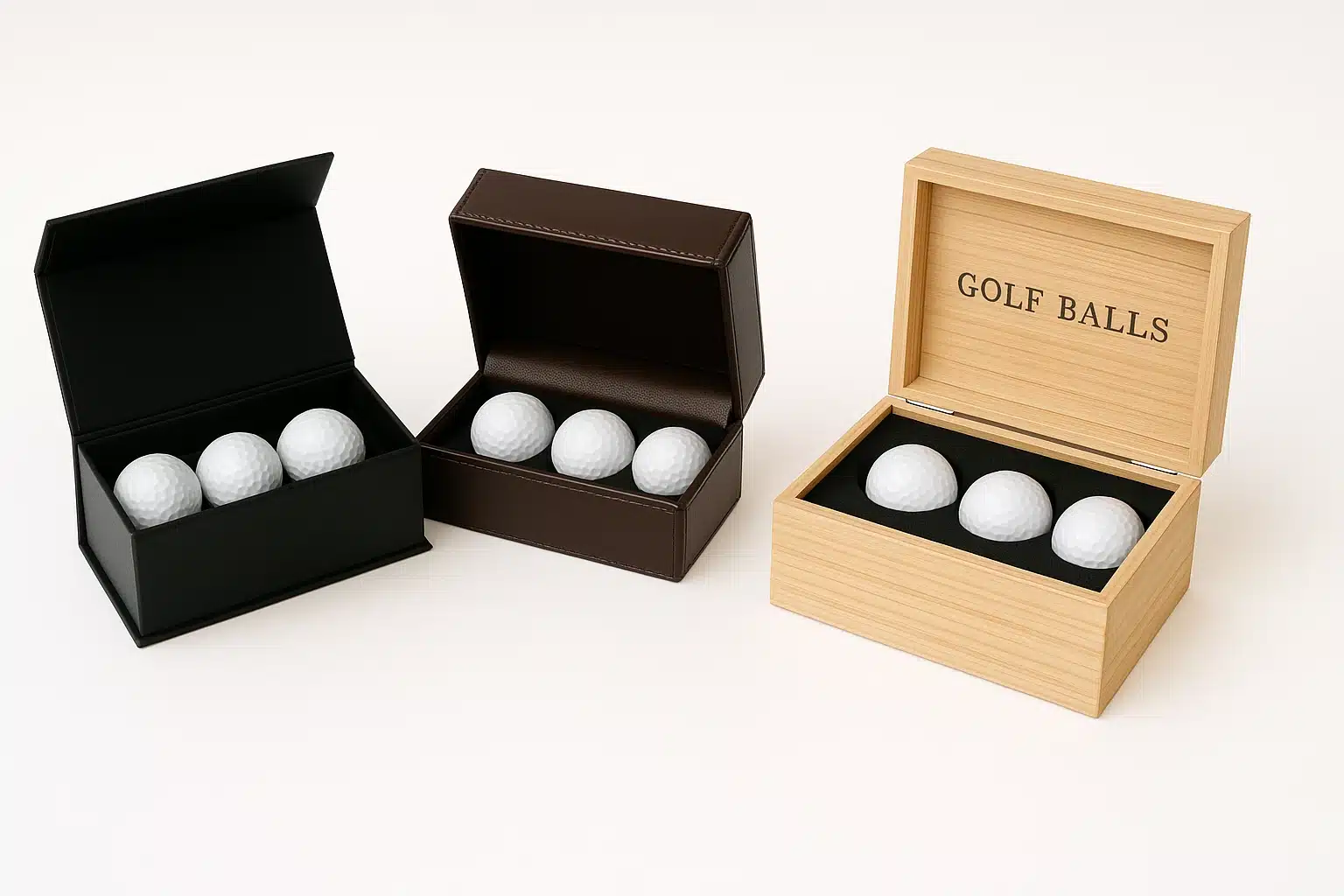

Wooden Gift Box + EVA

Adopt wooden boxes for limited or commemorative sets that need ceremony; confirm species and fumigation, and budget for weight and volume.

Best for: Limited editions, commemoratives, high-end gifting

Pros: Solid feel; engraving/metal plaques; strong unboxing

Limits: Costly; fumigation/species checks; heavier shipping

Typical MOQ (per SKU): 200–500 sets

QC: Moisture %, cracks/joints, finish uniformity, hardware alignment, engraving clarity, debris/odor

✔ True — Confirm species, moisture, and ISPM-15/fumigation needs

For pine, beech, paulownia, bamboo, or veneered MDF, check moisture %, finish uniformity, hardware alignment, and importing requirements. Freeze laser/UV settings with first-article samples.

✘ False — “All wood boxes ship without special formalities”

Ignoring species rules or moisture control causes customs holds, warping, odor, or cracking.

PU Leather Gift Box + EVA

Select PU-wrapped magnetic boxes for modern luxury with flexible colors and foil/deboss branding; control corner wrapping, bond strength, and VOCs.

Best for: Club membership gifts, corporate co-brands

Pros: Magnetic snap; premium textures; broad brand panel

Limits: Labor-intensive; odor/VOC risk; wrapping skill matters

Typical MOQ (per SKU): 500–1,000 sets

QC: Corner wrap, edge paint, bond strength, magnet pull, foil/deboss accuracy, odor/TVOC

✔ True — Control VOCs with adhesive choice and cure windows

Specify low-VOC glues, bake-off times, and edge-paint cures. Use odor chambers with acceptance thresholds. Check REACH/Prop 65 exposure for finishes/foils before mass runs.

✘ False — “Odor will just ‘air out’ during shipping”

Odor trapped in sealed cartons drives returns. Fix it in process, not after packing.

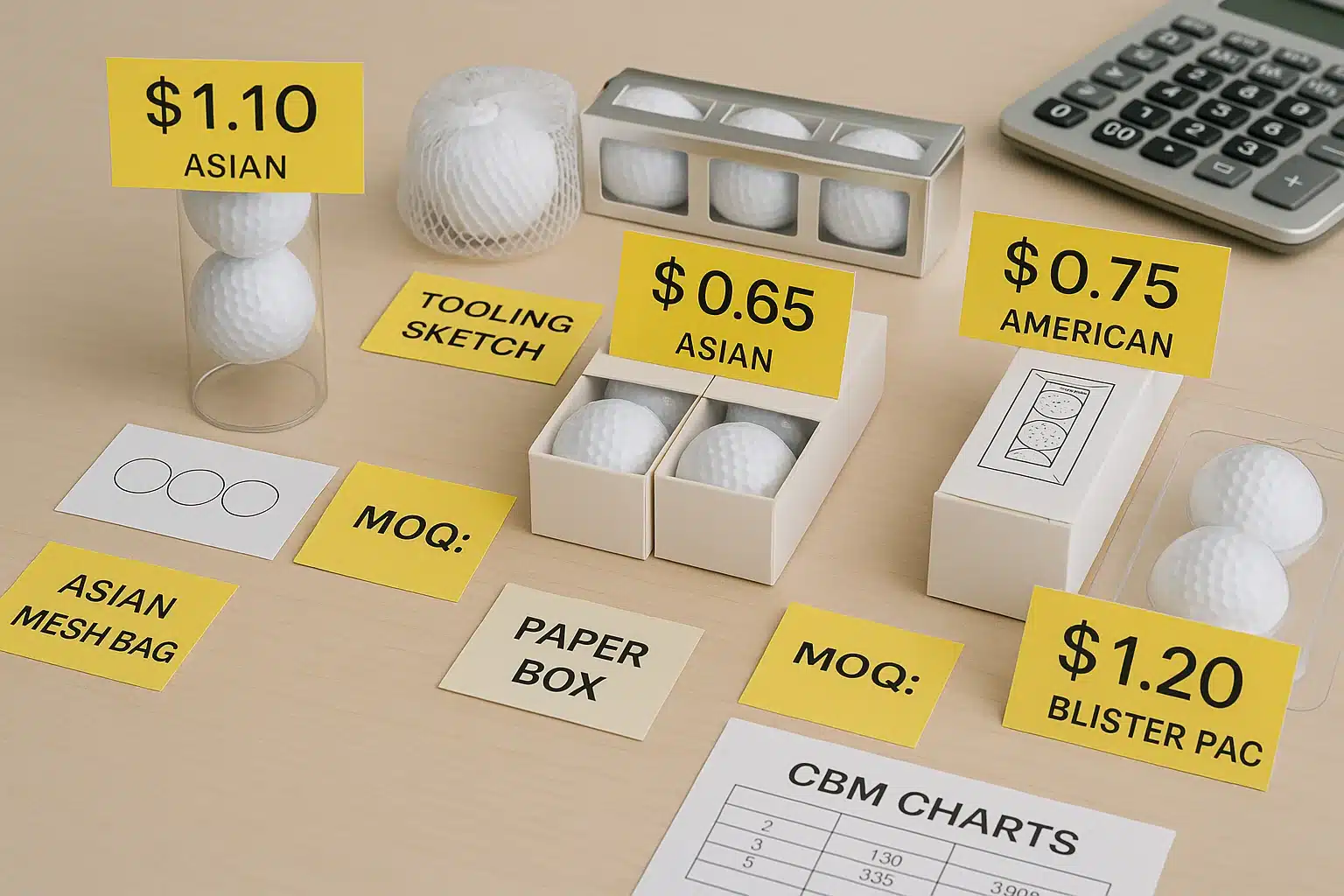

What are realistic costs and MOQs for OEM golf ball packaging by region?

Benchmark costs vary by region and process. Estimate unit cost as materials + printing + tooling/plates, then amortize one-time fees at your MOQ. Always add freight per dozen using CBM. The tables below summarize common EXW ranges for OEM golf ball packaging across five regions.

Paper Sleeve (3-ball, 350–400gsm)

| Region | Materials/pc | Plate/Die per SKU | 4C Print/pc |

|---|---|---|---|

| China | $0.03–0.06 | $50–150 | $0.02–0.05 |

| Taiwan | $0.04–0.08 | $60–180 | $0.03–0.07 |

| Japan | $0.08–0.20 | $120–300 | $0.06–0.15 |

| USA | $0.06–0.15 | $80–250 | $0.05–0.12 |

| Vietnam | $0.03–0.06 | $40–120 | $0.02–0.04 |

Dozen Box

| Region | Materials/pc | Plate/Die per SKU | 4C Print/pc |

|---|---|---|---|

| China | $0.10–0.25 | $80–200 | $0.05–0.10 |

| Taiwan | $0.12–0.28 | $90–220 | $0.06–0.12 |

| Japan | $0.20–0.45 | $150–350 | $0.08–0.20 |

| USA | $0.15–0.40 | $100–300 | $0.07–0.18 |

| Vietnam | $0.10–0.22 | $60–160 | $0.04–0.08 |

PET/PVC Tube (3-ball, with caps)

| Region | Materials/set | Screen/Foil per Color | Print/set |

|---|---|---|---|

| China | $0.10–0.22 | $30–80 | $0.02–0.05 |

| Taiwan | $0.12–0.26 | $35–90 | $0.03–0.06 |

| Japan | $0.25–0.50 | $80–180 | $0.05–0.12 |

| USA | $0.18–0.45 | $60–150 | $0.04–0.10 |

| Vietnam | $0.10–0.20 | $25–70 | $0.02–0.04 |

Blister (3-ball shell / 12-ball tray + card)

| Region | Materials/set | Tooling (one-time) | Card Plate | Print/set |

|---|---|---|---|---|

| China | $0.12–0.30 | $300–800 | $50–120 | $0.02–0.06 |

| Taiwan | $0.14–0.32 | $350–900 | $60–140 | $0.03–0.07 |

| Japan | $0.25–0.55 | $500–1,200 | $120–200 | $0.06–0.12 |

| USA | $0.20–0.50 | $400–1,000 | $80–180 | $0.05–0.10 |

| Vietnam | $0.12–0.28 | $250–700 | $40–100 | $0.02–0.05 |

Nylon Mesh Bag (12/24/50)

| Region | Materials/pc | Plate (silk/transfer) | Print/pc |

|---|---|---|---|

| China | $0.25–1.20 | $30–80 | $0.05–0.12 |

| Taiwan | $0.30–1.30 | $35–90 | $0.06–0.14 |

| Japan | $0.60–1.80 | $80–150 | $0.08–0.20 |

| USA | $0.40–1.60 | $60–120 | $0.07–0.18 |

| Vietnam | $0.25–1.10 | $25–70 | $0.04–0.10 |

Rigid Gift Box + EVA (3–6 ball cavities)

| Region | Box Materials/pc | EVA/pc | Plate/Die per SKU | Print/pc |

|---|---|---|---|---|

| China | $0.30–1.00 | $0.12–0.40 | $80–200 | $0.05–0.15 |

| Taiwan | $0.35–1.20 | $0.15–0.45 | $90–220 | $0.06–0.18 |

| Japan | $0.90–2.80 | $0.25–0.60 | $150–350 | $0.10–0.25 |

| USA | $0.70–2.20 | $0.20–0.55 | $100–300 | $0.08–0.22 |

| Vietnam | $0.35–0.90 | $0.12–0.35 | $70–180 | $0.05–0.12 |

E-commerce Accessories (for full BOMs) — Unit Material Cost, EXW

| Item (baseline spec) | Unit | China | Taiwan | Japan | USA | Vietnam |

|---|---|---|---|---|---|---|

| OPP/PE bag (single/multi) — inner bag for 1–3 balls, typical 40–60 µm, small size | USD /pc | 0.003–0.02 | 0.004–0.03 | 0.01–0.05 | 0.008–0.04 | 0.003–0.02 |

| Mailer (corrugated) — e-commerce mailer for 1 dozen, small/medium, E-flute | USD /pc | 0.20–0.80 | 0.25–0.90 | 0.40–1.20 | 0.30–1.10 | 0.22–0.75 |

| Tin can — promo tin for 2–3 balls, plain tinplate | USD /pc | 0.30–1.00 | 0.35–1.10 | 0.70–2.00 | 0.60–1.80 | 0.35–0.95 |

| Paper tube — small paper canister for 2–3 balls, kraft/white wrap | USD /pc | 0.25–0.55 | 0.28–0.60 | 0.50–1.10 | 0.45–0.95 | 0.26–0.50 |

✔ True — Quote unit price plus one-time tooling amortized at your volume

Plates, dies, and jigs are capitalized across your order (and repeats). Ask for amortization math so you can see SKU breakeven and reorder thresholds clearly before PO.

✘ False — “Tooling is one-time, so it’s basically free per unit”

If you skip amortization, either the first run or the repeat looks unfairly priced. Transparency prevents disputes.

Wooden Box + EVA (2–3-ball), premium

| Region | Materials/set | Jigs (one-time) | Branding (laser/UV/plate) | EVA/set | Typical MOQ |

|---|---|---|---|---|---|

| China | $3–8 | $50–150 | $0.10–0.50 | $0.12–0.40 | 200–500 |

| Taiwan | $4–10 | $60–180 | $0.15–0.55 | $0.15–0.45 | 200–500 |

| Japan | $8–20 | $100–250 | $0.30–0.80 | $0.20–0.50 | 100–300 |

| USA | $7–18 | $80–250 | $0.25–0.80 | $0.20–0.50 | 50–200 |

| Vietnam | $3–7 | $40–120 | $0.12–0.45 | $0.12–0.35 | 200–500 |

PU Leather Box + EVA (2–3-ball), premium

| Region | Materials/set | Dies (one-time) | Branding (foil/deboss/print) | EVA/set | Typical MOQ |

|---|---|---|---|---|---|

| China | $2.5–6 | $60–150 | $0.05–0.25 | $0.12–0.40 | 500–1,000 |

| Taiwan | $3–7 | $70–180 | $0.12–0.30 | $0.15–0.45 | 500–1,000 |

| Japan | $5–12 | $120–250 | $0.20–0.40 | $0.20–0.50 | 200–500 |

| USA | $4–10 | $80–200 | $0.15–0.35 | $0.20–0.50 | 100–300 |

| Vietnam | $2.5–6 | $50–140 | $0.10–0.25 | $0.12–0.35 | 300–800 |

MOQ Reality Check (common ranges)

-

Sleeve: 500–1,000 (per SKU)

-

Dozen: 500–1,000 (per SKU)

-

PET tube: 2,000–3,000 sets

-

Blister (3-ball): 3,000+; Tray: 5,000+

-

Nylon mesh: 500–1,000 (per SKU)

-

Rigid + EVA: 300–1,000 (per SKU)

-

Wooden box + EVA: 200–500 (per SKU)

-

PU leather + EVA: 500–1,000 (per SKU)

How fast can 10,000 balls be packed—and what takt times should you plan?

With parallel lines, most paper/mesh packouts complete within a workday; tubes/blisters are slower; wood/PU depend on woodworking/wrapping lines (about 1–2 weeks). For 10,000 balls ≈ 3,333 three-ball sets ≈ 833 dozens, plan machine times plus assembly hours and buffer for QC.

Baseline math: 10,000 balls = 3,333×3-ball sets ≈ 833 dozens

Typical takt & labor (conservative)

-

Sleeves: plates 0.5–1d; print/laminate/die 1–2d; ~28 labor-hrs (≈120 sets/hr/person)

-

Dozens: parallel with sleeves; ~4–5 labor-hrs (≈200 dozens/hr/person)

-

PET tubes: ~22 labor-hrs

-

Blister (3-ball): tooling 3–5d (first order), 28–37 labor-hrs

-

Nylon 12-ball: ~29 labor-hrs

-

Rigid + EVA: 28–48 labor-hrs

-

Wood box: sample 3–5d, woodwork 7–15d, 35–55 labor-hrs

-

PU box: tooling 2–4d, wrapping 6–12d, 40–60 labor-hrs

Throughput tips

-

Run multiple assembly lines; pre-kit inner trays; use simple jigs

-

Add belly bands/stickers? +1–2 labor-hrs per 1,000 sets

File name: oem-golf-balls-factory-packaging-gift-box.webp

Keywords: OEM, factory

How do you choose OEM golf ball packaging by use case, channel, and cost?

Map the pack to use case, handling intensity, and budget. For ranges and promos, Nylon/OPP wins. For standard retail, use 4×Sleeve + Dozen. For warehouse clubs, go Blister/Tray. For VIPs, use Rigid/Wood/PU + EVA. Always model landed cost per dozen—including freight from CBM.

By Use Case

Match format to usage intensity and brand goal; choose Nylon/OPP for speed and volume, Sleeve + Dozen for balanced retail, Blister/Tray for anti-tamper durability, and Rigid/Wood/PU for premium unboxing. E-com favors Dozen + mailer that survives drops and vibration.

-

Driving ranges/promo bulk: Nylon mesh or OPP big bag

-

Retail/distribution: 4×Sleeve + Dozen

-

Warehouse/club: 3-ball Blister or 12-ball Tray

-

Clubs/corporate/VIP: Rigid/Wood/PU + EVA

-

E-com direct: Dozen + ship-ready mailer

By Sales Channel

Align to channel display and backroom realities. Offline chains expect Sleeve + Dozen. Ranges need the lowest touch time. Clubs want premium presence. Tournaments accept dozens or gift boxes with event wraps. E-com prioritizes ship-ready dozens with low damage rates.

-

Offline chain/distributors: Sleeve + Dozen

-

Driving ranges: Nylon/OPP (or loose with PDQ)

-

Clubs: Rigid/Wood/PU

-

Tournaments: Dozen or Gift box (add event belly band)

-

E-com: Dozen + Mailer; promo bundles can use Tube/Blister

By Cost

From low to high cost: Nylon/OPP < Sleeve < Dozen < PET ≈ Blister < Rigid/Metal/Paper-tube < Wood/PU. Freight can flip choices: tubes/blisters inflate CBM; foldable paper often wins on landed cost, especially by air. Model per-dozen CBM and real freight tables.

Decision Matrix (scenario → recommended packaging)

| Scenario | Primary Option | Backup | Notes |

|---|---|---|---|

| Lowest cost / fast | Nylon Mesh | OPP | Minimal branding |

| Standard retail | Sleeve + Dozen | Dozen only (promo) | Industry norm |

| Warehouse club | Blister / Tray | Dozen + belly band | Tamper-evident |

| E-com FBA | Dozen + Mailer | Sleeve + Mailer | ISTA 1A/2A |

| VIP gifting | Rigid + EVA | PU Leather / Wood | CBM check |

| Limited edition | Wood + EVA | PU Leather + plaque | Numbered plate |

| Visual promo | PET Tube | Blister | Scuff-proof printing |

What makes packaging e-commerce/FBA-ready and compliant?

For e-commerce, design ship-ready dozens in mailers that pass ISTA 1A/2A. Use snug EVA or inserts to stop rattling, and add edge protectors where needed. Labeling, carton markings, and AQL sampling protect your brand in transit and in customer reviews.

E-commerce / FBA Readiness

✔ True — “Ship-ready” means passing ISTA 1A/2A with a full load

Design the dozen + mailer to survive corner/edge/face drops. Validate void fill, cavity snugness, and edge protection. Record pass/fail with photos and measurements for each sellable configuration.

✘ False — “A ‘Fragile’ sticker is enough for e-commerce”

Carriers ignore warnings. Only proven geometry/materials reduce breakage and claims.

Build “ship-ready” dozen packs: pair a robust dozen with a right-sized mailer and validated void fill. Run full-load ISTA 1A/2A drops (corners, edges, faces). For promotions, pre-kit sticker/belly band workflows and budget +1–2 labor-hrs per 1,000 sets.

-

Mailer material ranges: see E-commerce Accessories table

-

Tests: ISTA 1A/2A full-load drops; vibration as needed

-

Pack design: snug-fit cavities; avoid empty headspace; edge protectors for long-haul

Quality Control & Acceptance (AQL + item checks)

Adopt AQL 1.0–1.5 for appearance/functions; 0.65 for critical structure. Add material-specific checks: paper gsm/ECT/BCT; plastics thickness/haze/heat seal; soft goods seam/tear/logo fastness; EVA density/fit/odor; wood moisture/finish/hardware; PU wrap/bond/VOC.

-

Paper (Sleeve/Dozen/Mailer/Gift): gsm/ECT/BCT; ΔE≤2.0; 180° peel; snug fit

-

Plastics (PET/Blister): thickness; new material ratio; haze/scratch; heat-seal strength

-

Soft (Nylon/OPP): seam/tear; logo fastness (200 rubs); reseal performance

-

EVA: density/hardness/thickness; pocket fit; odor/TVOC

-

Wood: moisture %, finish uniformity, hardware alignment, engraving clarity, debris/odor

-

PU/Leather: corner wrap, edge coat, bond strength, magnet pull, foil/deboss accuracy, odor

✔ True — AQL is a sampling plan; batch control is essential

Use AQL 1.0–1.5 for appearance/functions and 0.65 for criticals, with golden samples and CAPA. Lab reports cover only tested batches—each shipment still needs inspection gates.

✘ False — “A certificate means the whole order is compliant”

Treat certificates as snapshots. Ongoing controls prevent drift between lots, shifts, and subcontractors.

Sustainability & Compliance Notes

Prefer paper-based and recycled content where practical. Scrutinize PVC usage; choose rPET or coatings that resist shelf scuffing. For wood, confirm fumigation/species. For PU/leather, manage REACH/CA Prop 65 exposure and VOC odor levels. Eco choices must still pass drop tests.

-

Wood: fumigation; avoid restricted species

-

PU/Leather: REACH/CA Prop 65; odor/TVOC limits

-

Plastics: scuff-resistant coatings; recycled PET where possible

What BOMs and next steps should you send to suppliers?

Send a clean BOM per scenario, plus dielines or cavity drawings. Ask for a DFM check, a ship-ready drop test plan, and cost split (materials/printing/tooling/freight). Lock MOQs and timelines. This package shortens quoting cycles and reduces back-and-forth.

Sample BOMs (ready to quote)

✔ True — Mass production must match the approved sample precisely

Once a sample is approved, the spec (ink, film, clear-coat, cure) should be locked and copied to bulk. Any deviation (fixtures, plate type, exposure time) must be pre-approved or repeatability and durability will drift.

✘ False — “If the sample looks good, the mass goods will match automatically”

Consistency needs controlled jigs, plate settings, ink batches, and cure windows—otherwise color, registration, and adhesion will vary.

Provide a structured BOM so factories price apples-to-apples. Include quantities, finishes, dieline versions, and test requirements. This speeds DFM and negotiation for your OEM golf ball packaging.

-

Retail (Sleeve + Dozen)

Balls (12) · 4×3-ball sleeves · 1×dozen box · insert (optional) · sticker/band (optional) · master carton · PDQ (optional) -

Bulk/Range (Nylon)

Balls (12/24/50) · nylon bag (drawstring) · hangtag (optional) · master carton -

Promo Visual (PET Tube 3-ball)

Balls (3) · PET tube (cap/base) · print/foil · hangtag/cord (optional) · master carton -

Warehouse (3-ball Blister)

Balls (3) · blister shell · color card · heat-seal · hang hole · master carton -

Premium (Rigid/Wood/PU + EVA)

Balls (2–6) · rigid/wood/PU box · EVA insert (cutouts) · metal plate/foil/laser · sleeve/dust bag (optional) · master carton -

E-com (Dozen + Mailer)

Balls (12) · dozen box (ship-ready) · mailer · void fill/edge protectors · compliance labels

FAQs for Golf Ball OEM Orders

What is the industry-standard retail pack?

4×3-ball sleeves inside one dozen box, then master carton for transport.

Which option has the lowest unit cost?

Nylon mesh or OPP. Minimal branding, fastest handling.

What’s best for warehouse clubs?

3-ball Blister or 12-ball Tray + Card for tamper evidence and rugged display.

Which is best for VIP gifts?

Rigid + EVA, PU leather, or Wooden boxes with custom badges.

How do I ensure ship-ready for e-com?

Use Dozen + Mailer and pass ISTA 1A/2A full-load drop tests.

When should I avoid tubes?

If air freight dominates, tubes/blisters raise CBM—paper may lower landed cost per dozen.

Key Takeaway + Conclusion

Choose Sleeve + Dozen for retail, Nylon/OPP for lowest cost, Blister/Tray for rugged display, PET tubes for visual promos, and Rigid/Wood/PU + EVA for premium gifts. Always validate CBM and drop-test performance to optimize landed cost per dozen across channels.

The best OEM golf ball packaging balances branding, durability, and logistics. Start from your channel, confirm MOQ and tooling, model landed cost (including CBM), and run drop tests. Use the decision matrix and BOMs above to request firm quotes and lock timelines with confidence.

You might also like — Top 3 Logo Printing Methods for OEM Golf Balls