You’re choosing between urethane and Surlyn. The rule of thumb is simple: if you swing fast and rely on greenside spin, urethane helps you score; if you want distance, straight flight, and durability per dollar, Surlyn wins most days. This guide turns that rule into clear specs, prices, and sourcing steps you can act on today.

Which is better for your game: Urethane or Surlyn?

If your driver speed is ≥95 mph (≈153 km/h) or you depend on one-hop-and-stop spin, pick urethane; if you’re a beginner/high-handicap or lose balls often, pick Surlyn for distance, straight flight, and durability. For most weekend rounds on public courses, Surlyn is steadier and more economical.

- Spin: Urethane ↑ (cast > TPU > Surlyn)

- Feel: Urethane softer; Surlyn firmer

- Distance: Driver carry similar; Surlyn tends to fly straighter

- Durability: Surlyn best vs scuff/cuts

- Price: Surlyn lower; urethane premium

Quick decision tree (30s)

-

Driver speed ≥95 mph (≈153 km/h) + firm greens or competitive rounds → Urethane (cast or TPU)

-

Driver speed <90 mph (≈145 km/h) or high lost-ball rate → 2-piece Surlyn

-

Mixed use / learning short game → Surlyn daily + urethane 1–2 weeks before events

Most golfers play more muni rounds than firm championship setups. In those conditions, ionomer/Surlyn covers resist scuffs, fly straighter, and keep your “good balls” in play longer. Urethane (cast or TPU) shines when you must control rollout on firm greens or when wedges decide your score. Don’t overpay for benefits you won’t use weekly—deploy them when they change outcomes.

✔ True — “More expensive” doesn’t mean “better for everyone”

Urethane adds short-game ceiling, but only helps if your scoring needs that extra bite. Many weekend rounds benefit more from Surlyn’s straightness and durability.

✘ False — “Urethane always lowers your score”

If you miss fairways or burn balls in rough/water, durability and dispersion matter more than wedge zip.

What are the material and construction differences?

Urethane covers (cast thermoset or TPU) can be made thinner and softer, raising wedge spin and feel; Surlyn (ionomer) is harder, scuff-resistant, lower-spin, and cheaper. Cast-thermoset urethane still leads TPU and Surlyn in maximum greenside spin, especially on firm/fast greens.

Here is the practical breakdown you can use with your supplier:

| Cover | Process | Typical Layers | Spin (Wedge) | Feel | Durability |

|---|---|---|---|---|---|

| Cast Urethane (thermoset) | Casting + curing + polish | 3–4 | Highest | Softest | Moderate |

| TPU Urethane (thermoplastic) | Injection/compression | 3 | High | Soft-medium | Good |

| Surlyn / Ionomer | Injection/compression | 2–3 | Lower | Firmer | Best vs scuff |

✔ True — Cast urethane & TPU are both “urethane”

But their spin ceilings differ: cast thermoset generally out-spins TPU in high-friction wedge shots.

✘ False — “TPU = cast urethane in all shots”

They’re closer off driver/irons; the gap emerges inside 50 yards and in wet grass.

Cast-thermoset vs TPU (definitions & impact)

Cast thermoset urethane forms a chemically cross-linked skin that can be tuned thin/soft for bite. TPU is re-moldable; it injects fast and keeps costs stable. Expect cast for spin ceiling, TPU for value + quick turns.

Ionomer/Surlyn concept & hardness range

“Surlyn” is DuPont’s ionomer brand: tough, resilient, higher Shore D hardness. It controls cover shear and keeps balls looking playable longer—ideal for practice, rough muni lies, and sandy environments.

Why “thin and soft cover” affects spin

Thinner, softer urethane engages grooves and increases friction + dwell on partial shots, raising spin and reducing rollout. On drivers (low loft, low spin loft), cover effects compress—distance stays similar, while Surlyn’s lower spin can straighten flight.

How do the manufacturing processes impact quality, lead time, and cost?

Cast-urethane needs formulation control, curing, and fine polishing; yield and takt are sensitive. Surlyn/TPU injection or compression cycles are faster and allow recyclable runners—friendlier to cost and lead time. At the same MOQ, urethane pricing and delivery risk are both higher.

| Process | Cycle Time | Yield Risk | Rework | Recyclability | Cost Impact | Seasonality |

|---|---|---|---|---|---|---|

| Cast Urethane | Slow | High (finish-sensitive) | Limited | Low | High | Bottlenecks 9–11 |

| TPU Injection | Fast | Medium | Some | High | Medium | Manageable |

| Surlyn Injection | Fastest | Low | Good | High | Low | Low |

✔ True — Finishing drives both price and schedule

Coating/printing adds $ and days. Double coats, UV, multi-color pad print, or gift boxes extend lead time.

✘ False — “Molding capacity is the only bottleneck”

Paint/print lanes and kitting often gate throughput, especially for cast urethane lines in peak season.

Cure & finish steps that drive yield

Cast urethane’s mix, degas, pour, cure, deflash, polish, paint chain multiplies small variances into scrap. Gloss control and logo registration are frequent rework drivers.

Injection benefits for small runs & fast turns

TPU/Surlyn short cycles + runner recycling enable low-MOQ pilots and quick replenishment. They’re ideal for house brands and DTC drops.

Seasonality (Sep–Nov) risk points

Urethane paint/finish queues lengthen in Sept–Nov. Lock colors/boxes early; concentrate late changes on core compression and pad-print only.

Who should choose urethane, and who should stick with Surlyn?

Choose urethane if driver speed ≥95 mph, you need one-hop-and-stop on firm greens, or you play competitive events often; choose Surlyn if you’re beginner/high-handicap, prioritize distance/straightness/durability, or lose balls frequently. Most public-course weekends favor Surlyn steadiness.

| Player Type | Swing Speed | Course | Priority | Recommended Cover |

|---|---|---|---|---|

| New/High-HC | <90 mph | Muni, softer | Distance, durability | 2-piece Surlyn |

| Improving | 90–95 mph | Mixed | Value + learning | Surlyn daily + TPU test |

| Competitive | ≥95 mph | Firm/fast | Greenside control | Cast urethane |

| Budget-sensitive | Any | Any | Cost per round | Surlyn |

For beginners, Surlyn usually wins on cost-per-round and straighter flight.

Swing speed & compression pairing

Match <90 mph with lower compression Surlyn/soft mantle for feel and launch; ≥95 mph players compress urethane covers reliably and unlock spin.

Course conditions (firm greens, wet rough)

Firm greens reward urethane. Wet rough also favors urethane’s groove-grass bite. On shaggy, abrasive lies, Surlyn survives longer.

Lost-ball rate & budget reality

If you lose >2 balls/round, the math pushes to Surlyn. Reinvest savings into lessons or wedges for a bigger scoring delta.

How big is the on-course performance gap?

Urethane generally spins more on wedges and chips (cast > TPU > Surlyn), improving stop/zip on firm greens; driver distance differences are small, while Surlyn flies straighter and resists scuffs better. Gaps concentrate inside 50 yards and in wet grass or high-friction grooves.

| Scenario | Driver | Iron Approach | 30–50 yd Pitch | Greenside Chip | Wet Rough | Bunker Check |

|---|---|---|---|---|---|---|

| Cast Urethane | Similar carry | Similar | Least rollout | Highest bite | Best | Best |

| TPU Urethane | Similar | Similar | Low rollout | High bite | Better | Better |

| Surlyn | Often straighter | Similar | More rollout | Lower bite | Lower | Lower |

- Dispersion: Surlyn’s lower driver spin can narrow lateral miss for many players.

✔ True — “Soft feel” doesn’t guarantee lower scores

Feel preference helps confidence, but dispersion, penalty strokes, and durability may move your card more.

✘ False — “Driver goes farther with urethane”

Distance differences are small; Surlyn’s lower spin can tighten dispersion.

Wedge-spin physics in simple terms

Spin = loft + friction + speed + contact time. Urethane raises friction/contact; Surlyn trades some friction for toughness.

Firm/fast greens vs muni greens

On firm/fast, rollout control is king → urethane. On soft muni, Surlyn’s straightness and cost-per-round often win.

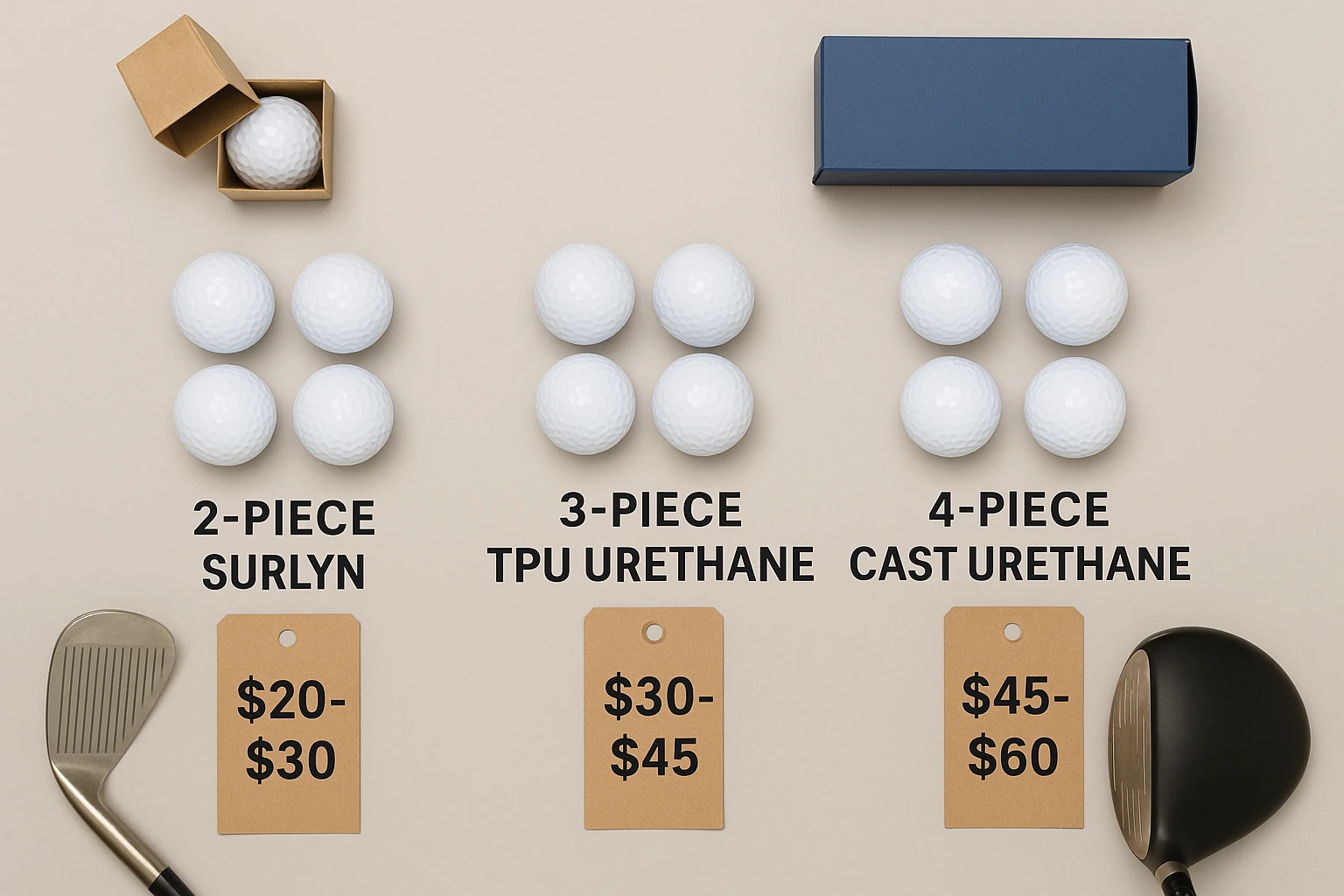

What about price bands, MOQ, and cost control?

Typical EXW/FOB bulk per piece: 2-piece Surlyn $0.32–0.60; 3-piece urethane $0.60–1.20; 4-piece urethane $0.80–1.50. Lower MOQs push unit price up. Use simple pad-print and generic boxes to control cost; choose TPU before cast for budget-limited upgrades.

| Layers | Cover | Price Band | MOQ Sensitivity | Notes |

|---|---|---|---|---|

| 2 | Surlyn | $0.32–0.60 | Low-medium | Practice/retail value workhorse |

| 3 | Urethane (TPU or entry cast) | $0.60–1.20 | Medium-high | DTC/house brands sweet spot |

| 4 | Urethane (mostly cast) | $0.80–1.50 | High | Finish capacity drives swings |

What moves price (layers, paint, packaging)

Layers and cover are base. Paint stacks, UV coats, multi-color logos, windowed boxes add cost/days quickly.

Low-MOQ tactics that matter more than materials

Hold one color, single-color pad print, generic boxes, and fixed insert. Keep variation in core compression or print only.

When urethane “is worth it”

If your scoring bottleneck is greenside rollout and you play firm greens or events, urethane’s premium is justified. Otherwise, prioritize Surlyn volume and coaching.

Regulatory and price guidance as of Sep 2025. Re-check model listings and seasonal quotes before purchasing.

Can Surlyn be used for tournaments — and is it tournament-legal?

Yes. If the ball model is on the conforming list, Surlyn is legal and common in amateur/club events. If you occasionally compete or need more check on firm greens, switch to urethane 1–2 weeks before the event to adapt greenside feel; otherwise keep Surlyn for daily play.

| Event Type | Course Speed | Your Short-Game Need | Recommendation | Prep Timeline |

|---|---|---|---|---|

| Club/Muni | Medium | Normal | Surlyn OK | None |

| Firm/Champ | Fast | One-hop stop | Urethane | 7–14 days |

| Mixed League | Varies | Confidence | Two-ball strategy | 1 week |

✔ True — Surlyn balls can be tournament-legal

Legality depends on the conforming list, not cover chemistry.

✘ False — “Pros play urethane, so Surlyn is illegal”

Usage by pros ≠ rules of play. Many amateur events see Surlyn models in the field.

Conforming-list basics (quick)

Check the listing for the exact model. Keep a screenshot in your tourney bag. Update with model refreshes. Check the USGA and R&A Conforming Lists for the exact model name and version.

Two-week urethane adaptation plan (30–50 yd focus)

Spend 10–15 minutes/day on 52°/56° partials: fixed land spot, measure rollout, adjust trajectory/face.

Post-event revert to Surlyn to save cost

Switch back for practice and casual rounds. Keep feel continuity by matching compression and sound where possible.

Sample China factories (for context & sourcing)

Multiple plants offer both covers; Surlyn and TPU runs are better for fast turns, while cast-urethane lines face paint/finish bottlenecks in peak seasons. Use small test lots to compare spin, rollout, and scuffing before committing.

| Factory | City/Province | Materials |

|---|---|---|

| Golfara | Ningbo/Zhejiang | Urethane & Surlyn (MOQ 1000 pcs) |

| JTS (Xiamen JTS Sports Equipment) | Xiamen/Fujian | Urethane & Surlyn |

| Xiamen MLG Sports Equipment | Xiamen/Fujian | Urethane & Surlyn |

| GTS Golf (China) LLC | Dongguan/Guangdong | Mainly Surlyn |

Ningbo/Xiamen clusters overview

Ningbo and Xiamen host dense tooling/printing ecosystems—useful for box and pad-print agility.

MOQ & lead time norms by process

Surlyn/TPU: faster cycles, better for low-MOQ trials. Cast urethane: plan buffers for finish.

How to brief a test order

Specify same core, prepare 12+12 balls (Surlyn vs urethane), and define 52°/56° wedge land-spot tests.

FAQ

Is urethane always better for scoring?

Not always. Urethane lifts greenside spin and feel, but if penalties, dispersion, and scuff-outs dominate your card, Surlyn can save more strokes per dollar.

Use urethane when firm greens or competition make rollout control decisive. Otherwise, Surlyn’s straight flight and durability reduce mishits’ damage and lower cost per round—especially if you lose balls. Many golfers score best by playing Surlyn daily and urethane only before events.

Can Surlyn balls stop on firm greens?

Yes, but they roll out more. You can still stop Surlyn with higher trajectories, landing into up-slopes, or using more loft.

Surlyn has lower friction at impact on partial shots, so chips and pitches release more. On firm greens, adjust: land shorter, use a higher-lofted wedge, or open the face for added spin loft. If you routinely need “one-hop stop,” consider a urethane option for tournament weeks.

What swing speed should consider urethane?

Around ≥95 mph driver speed is a common threshold, especially if greenside control affects scoring.

At higher speeds, you compress the ball consistently and can exploit urethane’s friction and thin-cover benefits. If you’re 90–95 mph and improving, test TPU urethane against Surlyn in a 12+12 protocol and decide based on rollout and dispersion, not hype.

Are Surlyn balls tournament-legal?

Yes—if the exact model appears on the conforming list, cover material doesn’t matter.

Many club and amateur events see Surlyn models in play. Confirm the model name and keep a proof handy. Don’t assume legality from brand alone; verify after packaging or model refreshes, then practice with that ball to maintain feel.

TPU urethane vs cast urethane—what’s the real difference?

Both are urethane, but cast thermoset typically delivers a higher wedge-spin ceiling; TPU wins on cost and lead time.

TPU is injection-friendly and recyclable; cast involves curing and more finishing steps. Driver and full-iron shots show small gaps; the difference appears inside 50 yards, on firm greens, or in wet grass where friction matters.

Will Surlyn feel too hard for putting?

It’s firmer, but speed control is trainable; consider low-compression 2-piece or soft-mantle 3-piece Surlyn for feel.

Putting feel blends cover, core compression, and sound. If Surlyn sounds clicky, try a lower-compression Surlyn build, adjustable insert putter, or slightly softer ball for events while keeping Surlyn for high-wear practice rounds.

How much more does urethane cost at low MOQ?

Expect a noticeable premium. Typical ranges: 3-piece urethane $0.60–1.20; 4-piece $0.80–1.50, with low MOQ pushing unit costs higher.

Finishing capacity and scrap amplify at small lots, especially in peak seasons. Control variables (one color, simple box) and trial TPU before cast to keep the upgrade economical.

If I play one event a year, should I switch to urethane?

Yes—switch 1–2 weeks prior and practice 30–50-yard shots; go back to Surlyn afterward.

A short adaptation window lets you calibrate rollout and spin. After the event, Surlyn keeps costs down and durability up, preserving urethane sleeves for times when they change outcomes.

What’s the simplest way to test before ordering bulk?

Run a 12+12 A/B with the same core: Surlyn vs urethane, fixed land spot, measure rollout and scuff after 52°/56° wedges.

Document land-spot distances, rollout averages, and cover wear after set reps. Decide within a week and lock materials, then keep packaging simple to stabilize yield and lead times.

Will Surlyn crack or scuff less on rough muni courses?

Generally yes. Surlyn’s ionomer cover resists shear and abrasion better, keeping more balls playable.

If your course has sandy bunkers, tree roots, and cart-path brushes, Surlyn reduces “retire-the-ball” moments. That translates into lower effective cost per round and less mid-round ball swapping.

Conclusion

Use this rule: play Surlyn for daily rounds and practice; deploy urethane when firm greens or events make rollout control decisive—ideally with ≥95 mph driver speed. Lock materials via a 12+12 test, keep print/box simple, and book finish capacity early in peak season. For sourcing or pilot runs, we can help align cover choice with your MOQ and calendar.

You might also like — 3 Piece vs 4 Piece Golf Balls: Which One Is Right for You?