To purchase OEM golf balls in Asia, follow these steps:

- Define specs and quantity

- Shortlist manufacturers via Google, Alibaba, Made-in-China, or trade shows

- Verify OEM capability, export history, MOQ, and USGA/R&A conforming model

- Request samples and validate performance

- Negotiate price, lead time, packaging, and payment (e.g., 30/70 T/T); set a QC/AQL plan

- Choose FOB or DDP; prepare HS code and import documents; place the order

- Book a pre-shipment inspection

Why buy OEM golf balls from Asia?

Asia clusters materials, tooling, coating, printing, and packaging, enabling faster sampling, steadier lead times, and lower total landed cost. Asia accounts for ~62–66% of global golf ball output.

What quality/spec tiers can Asian OEM golf ball manufacturers deliver?

Asia covers the full ladder: 2-piece ionomer for promo/range, 3-piece ionomer/urethane for mid-high, and tour-grade 4–5-piece cast-urethane built in Thailand, South Korea, Taiwan, and Japan. Much of this capacity is brand-owned or partnered, so USGA/R&A conforming models are realistic when constructions don’t change.

Thailand’s Titleist Ball Plant 4 anchors tour-grade urethane for Asia/Europe; South Korea’s capacity stepped up after TaylorMade acquired Nassau; Taiwan’s Foremost-led cluster runs both urethane and ionomer well; China anchors volume with high-throughput 2-piece ionomer, flexible MOQs, fast artwork-to-pack execution, and expanding 3-piece urethane lines (notably in coastal provinces).

Together these hubs enable dual-sourcing—e.g., TH/KR for tour-grade urethane plus TW/CN for volume/packaging—without drifting spec.

How do Asian ex-factory prices compare with US/EU for like builds?

At volume, Asia’s working EXW/FOB bands are: 2-piece ionomer $0.28–0.65; 3-piece urethane $0.90–1.90; 4–5-piece cast-urethane $1.60–3.50. As a price index, 2023 export unit values run China ≈ $0.41/ball, Taiwan ≈ $0.53, versus the United States ≈ $1.33—a mix-level gap of roughly 60%–70%.

Because US/EU plants prioritize house brands, true OEM windows are rare; where available, quotes often sit at the upper end of Asia’s ranges (labor/compliance overhead) and may exceed them on tour-grade builds.

What production lead times should I plan in Asia, and are they faster than US/EU?

Plan ~25–45 days for 2-piece repeats and ~35–90 days for urethane; first orders add tooling/PPS time. Asia’s dense clusters and dedicated OEM capacity are typically ~10%–30% faster than Western OEM windows for comparable builds.

Mechanically, 2-piece ionomer needs ~2–5 processing days; cast-urethane needs ~5–12 plus coating/curing windows, which drive longer bands. Pilots are ~30 days for a few thousand balls once artwork is locked; industry guidance pegs most OEM cycles at 3–8 weeks ex-factory.

In the US/EU, turnaround is fast for logo-on-existing balls (not OEM) in 2–3 weeks, but full private-label builds are scarce and usually scheduled after house brands—hence longer windows.

Which Asian countries produce OEM golf balls?

Think in two lanes: tour-grade cast-urethane built in Thailand, South Korea, Taiwan, and Japan; and high-scale ionomer—including practice balls—made in China, Vietnam, Indonesia, and Taiwan. Choose the lane that matches your positioning, calendar, and budget.

| Country/Region | Main types | Top destinations | Ref OEM EXW/FOB (20k bulk) | Lead time (first/repeat) |

|---|---|---|---|---|

| Thailand | Cast-urethane 3–4-pc | US/EU/JP/UK/KR | PU $1.90–2.60; 2-pc $0.70–1.00 | 45–90/35–60d |

| Taiwan | PU 3–4-pc + 2-pc | US/EU/JP/UK | PU $1.10–1.90; 2-pc $0.40–0.65 | 35–60/25–40d |

| China (Mainland) | 2-pc core; some 3-pc PU | US/KR/EU/UK/JP | 2-pc $0.28–0.45; 3-pc PU $0.75–1.10 | 25–45/18–30d |

| South Korea | PU 3–4-pc | US/JP/UK/AU | PU $1.60–2.30; 2-pc $0.70–1.00 | 45–75/35–55d |

| Vietnam | 3-pc PU/ionomer; 2-pc | US/JP/CA/UK/KR | 3-pc PU $0.90–1.40; 2-pc $0.32–0.55 | 30–50/25–40d |

| Indonesia | Group lines across tiers | US/EU/UK/JP-KR | PU 3–4-pc $1.20–1.80; 2-pc $0.45–0.80 | 45–75/35–55d |

| Japan | High-end/competition | KR/US/EU/UK | PU 4-pc $2.30–3.50; 3-pc $1.80–2.60 | 60–120/45–90d |

How should you use Thailand and South Korea?

Treat them as anchors for tour-grade urethane. You exchange longer coating/curing windows for repeatable performance and fewer field complaints. If your brand serves better players, these lines protect your reviews.

Book capacity early and nail paint/clearcoat specs. South Korea’s vertical integration under major brands often stabilizes upstream resin/paint supply, which is why I like it for flagship SKUs.

Where do Taiwan and China fit?

Taiwan is the two-lane specialist—urethane and ionomer both run well with strong printing/packaging. China wins on scale, flexible MOQs, and speed, especially for promo, sleeves, and gift sets.

For a balanced lineup—2-piece volume plus a 3-piece urethane hero—Taiwan + China is my default dual-source. It hedges schedule risk and keeps your unit economics sane.

What’s the role of Vietnam and Indonesia?

Vietnam is the fast riser for 3-piece builds and efficient 2-piece volume; Indonesia’s group plants deliver steady mid-to-upper tiers. Both work when you want value and quality without babysitting every process.

In Vietnam, pay extra attention to QC governance—AQL discipline and change notices need named owners. Indonesia’s group standards make mid-high SKUs feel predictable.

Is Japan viable for OEM if prices are high?

Yes—when you need a flagship. Japan’s craft and process control justify premium ex-works, but OEM windows are scarce. Be precise and early; those lines will hold you to your own spec.

National average export prices don’t represent these flagships. If you choose a Japanese OEM, you’re buying scarcity and craftsmanship alongside performance.

✔ True — Country averages are mixed baskets

“Dollars per ball” at the country level blends cheap practice balls with multi-layer urethane. Your OEM quote for cast-urethane will be well above the average, by design.

✘ False — “Average price predicts my tour-grade quote”

Construction and finishing drive price. Averages are a macro lens, not a PO number.

What makes a reliable OEM golf ball manufacturer?

Assess four dimensions: clear market positioning, solution-level advice (not just order-taking), punctual communication, and written responsibility. When a manufacturer evidences all four—data, options, cadence, and accountability—it is fit to handle OEM golf ball programs.

How should a manufacturer define its specialization and fit?

Start with three blunt questions: 1) highest-volume model (layers, cover, compression), 2) top destination countries, 3) main customer types. If a plant can’t explain its own positioning, it’s guessing on yours. Fit beats breadth. A tight-control 2-piece ionomer specialist can outperform a shaky 4-layer line.

✔ True — Higher spec doesn’t equal more professional

A factory that is No.1 in consistent 2-piece ionomer may serve your promo lineup better than a shaky 4-layer shop. Professional means fair pricing, on-time delivery, fast responses, and repeatable execution—spec alone is not the definition.

✘ False — “If they can do tour-grade, they’re automatically best for me”

Tour capability is a craft signal, not a service guarantee. If your use case is retail promo volume, the wrong “elite” partner can add cost, delay, and rework.

Will the factory bring solution-level advice, not just take orders?

Modern OEM isn’t “you bring the recipe, we cook.” Golf ball manufacturers that can provide various specialized solutions and recommendations are clearly more professional: logo process by use case (pad vs UV vs heat), sleeve/dozen box choices that protect brand and budget, and trade-off charts for 2/3/4/5-piece builds with timing and cost impacts.

If a manufacturer only answers “yes” and sends a number, consider passing. A professional plant proposes two or three viable paths and quantifies each. Example: matte clearcoat adds cents but lifts shelf appeal; simplifying the dozen box can recover that cost. This advisory behavior signals multi-channel experience and practical know-how.

✔ True — Longevity helps, but fit matters more

A 30-year plant may prioritize million-ball buyers. If you buy 10–20k at a time, you need a team that treats your calendar and price as first-class, not leftover capacity in peak season.

✘ False — “Oldest factory = best for my order size”

Age alone doesn’t equal fit. Professional, to you, is timely service and consistent delivery at your size and cadence.

How should I test punctuality and communication discipline?

Make time visible. Set micro-SLA checkpoints: 24–48-hour quote turnaround, five business days to counter-sample, and a weekly written update. Professionals warn early and close issues in writing; that habit predicts vessel performance better than a one-off quick quote.

Practical tells: do emails get acknowledged within 24 hours? If they promise five days for samples, do they land on day five without excuses? Are multiple contacts aligned or contradictory? If you waited three or four days for the first reply and then got a slick price on day five, that’s not punctuality; that’s luck.

✔ True — “On time” is a measured habit

Acknowledgment in 24h, weekly updates, and early risk flags correlate with shipments that meet vessel cutoffs. Set the cadence early and hold to it.

✘ False — “A great price compensates for tardy habits”

Delays erase savings. Late culture at RFQ time usually becomes missed trucks at shipment time.

How do I confirm responsibility and risk ownership up front?

Write responsibility into the PO and prove it on a small job. Run a 1–3k-ball trial to test PPS, AQL results, and third-party PSI behavior.

Responsible plants disclose small changes immediately—color shift, carton weight, coating tweaks—and wait for written approval. If someone claims “99% pass,” ask who pays for the 1–2% and how quickly; real responsibility shows up in cost-bearing clauses and demonstrated behavior.

✔ True — USGA/R&A status is model-specific and persists if unchanged

If a ball’s materials and construction are unchanged, an older conformance proof still indicates the ball meets the standard, even if the factory doesn’t re-test annually. Annual re-tests are costly; stability matters.

✘ False — “No fresh certificate, so they must be unprofessional”

Certificate recency alone is not a professionalism test; unchanged builds and measurable specs carry more weight for repeat orders.

What is the step-by-step purchase process?

Scope the spec, shortlist, verify capability, run samples, lock commercials, set logistics and documents, and schedule PSI. Assign owners, dates, and pass/fail gates at every step.

How should I scope specs and shortlist manufacturers?

Define construction (2/3/4/5-piece), cover (ionomer vs urethane), compression target, logo colors and Pantone codes, packaging type, and quantity tiers. Then search Google, Alibaba, and Made-in-China; cross-check official sites, filings, and export footprints; narrow to three to five factories.

Keep a discovery grid: contact, specialization, MOQ, lead-time bands, PSI stance, and recent destinations. For a urethane 3-piece retail SKU, Taiwan or South Korea often fit. For ionomer 2-piece promo volume, China or Vietnam wins. Dual-source early to keep options alive.

How do I validate capability and references?

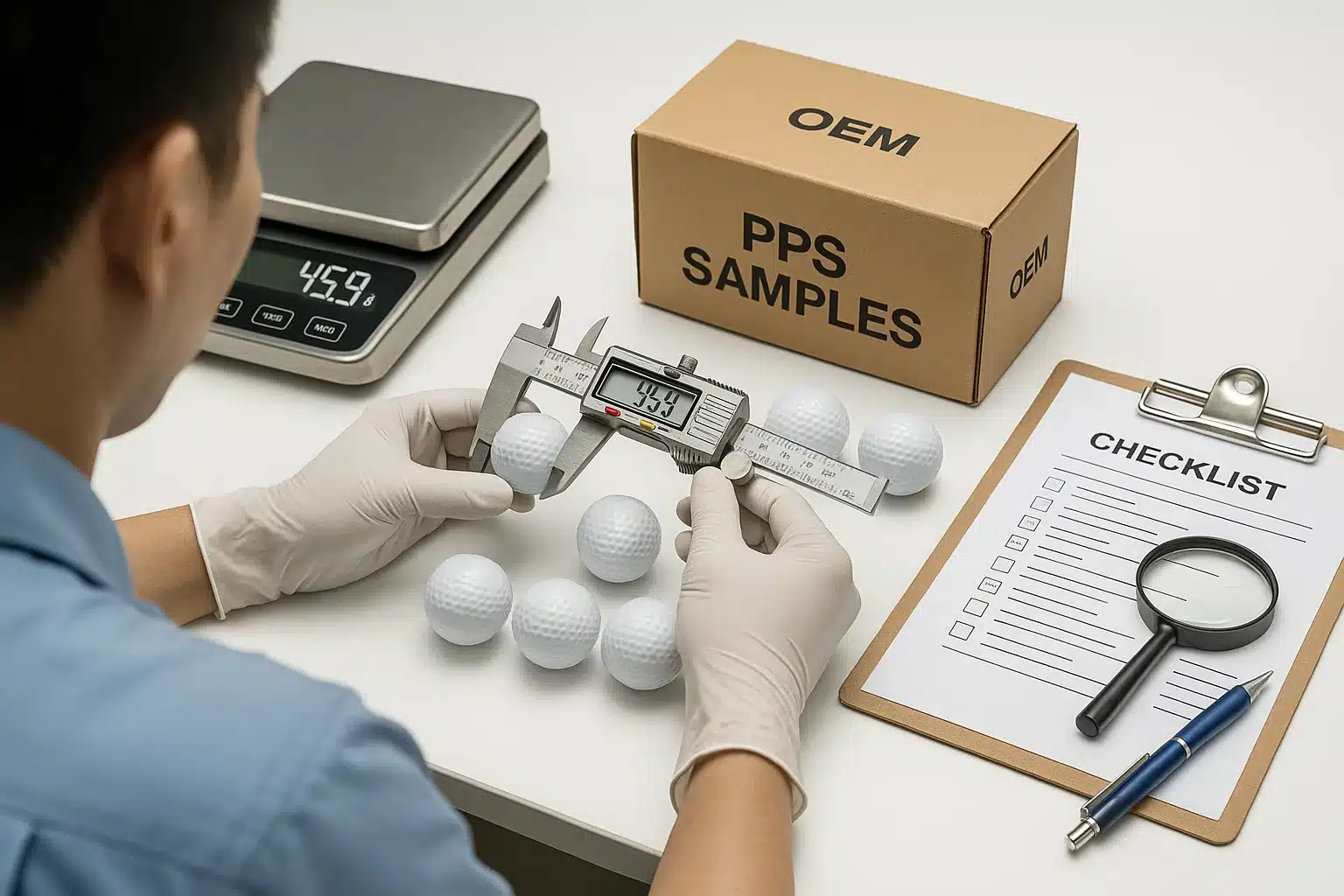

Ask for lists and process maps that match your market. Confirm they accept third-party PSI. Order a counter-sample and a PPS built on the real line—those are your gates.

Evaluate weight/diameter, compression feel, coating quality, print alignment, and durability. The PPS must match your counter-sample within tolerances; if it drifts, stop and re-shoot before booking a vessel.

How do I choose Incoterms and prepare documents?

Pick FOB for control, DDP for convenience, and use CIF to compare all-in costs when needed. Align HS code 950632, labeling, and destination rules before any print starts. Standardize your document pack—invoice, packing list, BL/AWB, declarations.

Have the manufacturer send draft documents before the CY cutoff. Fixing HS typos or carton counts on the dock wastes days; fixing them at the desk takes minutes.

What should the week-by-week timeline look like?

Use a simple cadence: RFQ week → sampling week → PPS week → production window → PSI week → vessel week, with buffers. When dates live on one line for all parties, commitments stick—especially in peak season.

✔ True — Trial order first, then scale

A paid pilot of 1–3k balls reveals behavior you won’t see in email: response speed under pressure, change control, and how they handle small defects. It’s the cheapest insurance you’ll buy.

✘ False — “We’ll fix it on the big order”

Problems scale with volume. If a manufacturer can’t pass a tidy pilot, a container won’t cure it.

How should you run samples and performance checks?

Make PPS the gate to production. Approve measurable targets: appearance and registration, weight/diameter windows, compression feel, and durability. If the PPS drifts from the counter-sample, stop—the line isn’t locked.

What must pass before mass production?

Two things: a signed counter-sample and a PPS built on the real line. The PPS must match weight, diameter, compression, coating, and print alignment within your tolerances. If not, re-shoot before booking a vessel.

Set acceptance ranges per metric and keep the same tools/lighting across approvals. Stamp photos and retain witness samples. Hard gates early become smooth sailings later.

| Metric | Method | Target/Tolerance | Pass/Fail |

|---|---|---|---|

| Appearance & printing | Visual check | No major defects; registration on mark | ☐ / ☐ |

| Weight & diameter | Scale/caliper | Within specified window | ☐ / ☐ |

| Compression & feel | Instrument/blind test | Matches target profile | ☐ / ☐ |

| Durability | Repeated strikes/abrasion | No cracks/chips/peel | ☐ / ☐ |

How do you test performance without a full lab?

Run controlled “garage tests” plus field swings. Use a launch monitor for speed/spin/launch, a high-repetition wedge test for coating/paint resilience, and keep all numbers in a simple sheet. Document, don’t assume.

For packaging-heavy SKUs, add a CTN compression or drop check. It doesn’t replace a certified lab, but it catches surprises before a container is sealed.

What else do buyers often ask?

In my 20 years in this business, many first-time clients have asked similar questions — and I suspect you might be thinking about some of them too. I’ve listed them below — they might come in handy if you ever consider sourcing golf balls from Asia.

What’s a reasonable MOQ?

Hundreds to low thousands, depending on construction and pack/print minimums; complex urethane builds and premium boxes require higher thresholds.

For pilots, start with 1–3k balls to validate consistency and after-sales response. For promos, 10–20k is efficient. Confirm logo color counts and carton specs early.

How long after sample approval can I ship?

Commonly two to five weeks, but urethane coating/curing windows, paint changes, and peak-season queues add time.

I suggest budget 30–60 days for first orders and 18–40 for repeats, country-dependent. Tie lead time to a named vessel cutoff—not “around end of month.”

Can I mix models in one PO?

Yes—if pack and print minimums are met and labels are precise.

Bundle models that share coating or print setups to save changeovers. Separate CTNs by model and use distinct barcodes to keep 3PLs sane.

How do I ensure logo color accuracy?

Provide Pantone codes, approve drawdowns, and sign counter-samples with position marks.

Ask for lighting conditions (e.g., D65). For matte or special varnish, budget extra days; they add cost but elevate shelf appeal.

Do I need a USGA/R&A conforming model?

Required for competition; optional for promo/practice.

If you sell into tournaments, specify a currently conforming model in your PO. For non-tournament retail, consistent physical specs still matter—conformance is your design boundary, not a one-time pass.

Golfara helps brands ship faster with low MOQs (from 1,000 pcs), printed samples in ~3 business days, and ≤10-day small-batch production. Just send your target spec — our team replies in ≤12 hours with a priced, risk-controlled plan.

You might also like: How to Order Custom Golf Balls in Bulk with Your Logo?