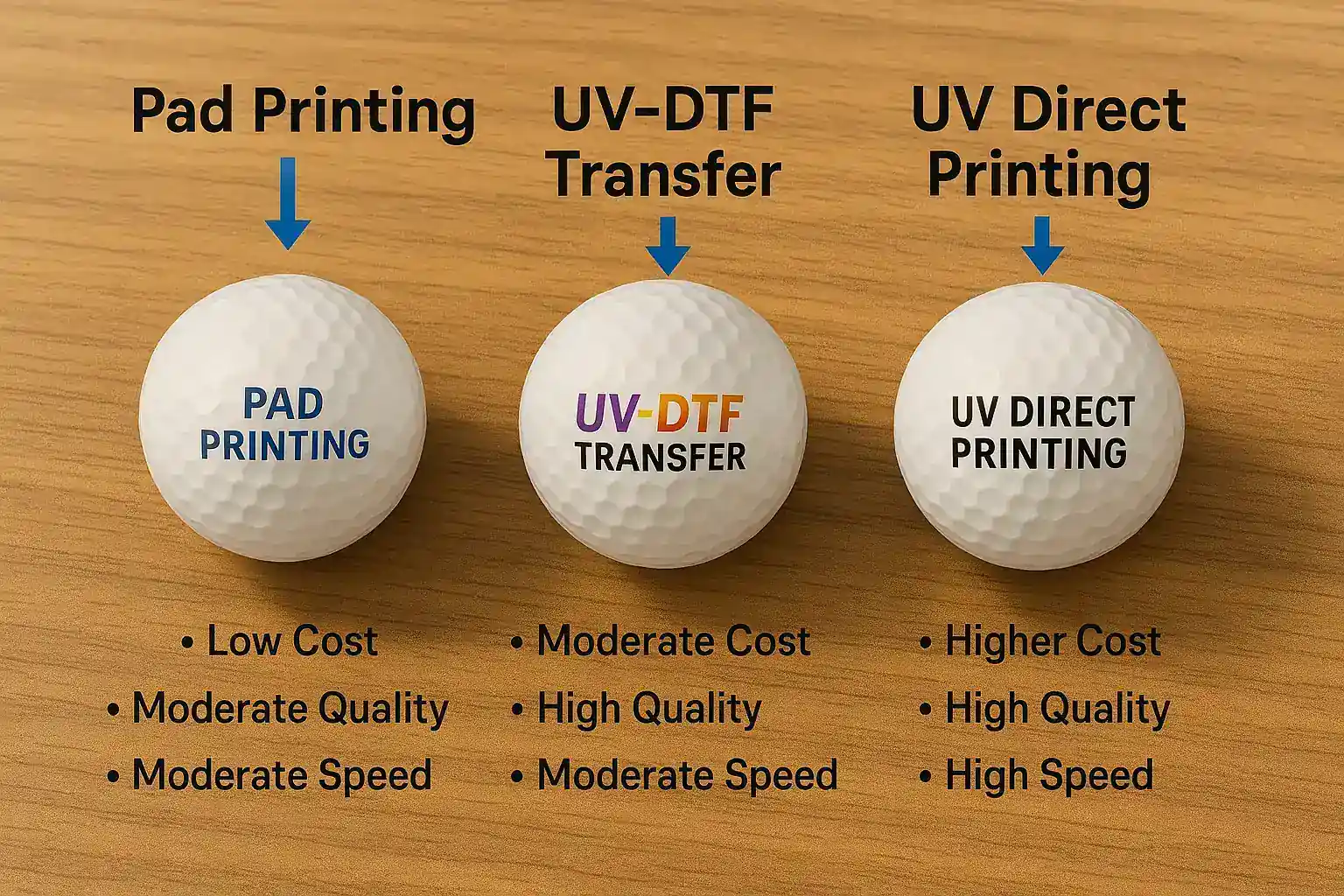

For bulk OEM golf ball production (≥1,000 units), the top three logo printing methods are Pad Printing, UV-DTF Transfer, and UV Direct Printing. Pad minimizes cost and boosts durability, UV-DTF delivers premium visuals under clear-coat, and UV Direct speeds multi-design sampling—the practical core of OEM golf ball logo printing methods.

How do you choose the right logo printing method for OEM golf balls?

Pick Pad Printing for large runs and durability, UV-DTF Transfer for complex, premium visuals with clear-coat protection, and UV Direct Printing for fast sampling and small, varied orders. Anchor your choice on four drivers: order size, visual complexity, budget, and throughput—all common in OEM golf ball logo printing methods.

✅ By order size and type

For ≥10,000 balls with simple one-side logos, Pad Printing gives the lowest unit cost and the highest, most stable throughput. For 2,000–5,000 balls with complex, multi-color art, UV-DTF Transfer balances quality and yield. For <1,000 balls or many SKUs, UV Direct is agile and economical overall.

Order size sets the economics. Pad Printing scales best because it integrates with coating lines and fixtures, keeping consistency and wear resistance high. UV-DTF handles premium visuals at reasonable mid-volume cost when coated. UV Direct avoids plates and speeds approvals for small custom batches.

✅ By visual priority

If you need gradients, photos, or micro-text, UV-DTF Transfer wins on fidelity after clear-coat. If you need clean 1–2 colors and crisp edges, Pad Printing is unbeatable on curved surfaces. If you need many designs with frequent swaps, UV Direct Printing saves prep time.

Visual goals matter. Pad Printing is not ideal for photographic detail or soft gradients. UV-DTF can carry complex art with smooth edges and depth, then lock it under varnish. UV Direct renders color-rich designs quickly, but its scratch resistance typically trails coating-based systems.

✅ By budget and timeline

Pad Printing minimizes cost per ball at scale and finishes 800–1,500 balls per hour. UV-DTF’s material plus labor raise unit cost, and the process is slower. UV Direct avoids plate fees and speeds sampling, but per-ball cost and wear performance are mid-range.

Lead time mixes setup, printing, coating, and QC. Pad Printing uses plates and jigs but flies once set. UV-DTF adds film creation, transfer, and over-coat. UV Direct reduces setup and prints multiple designs with minimal downtime.

Which golf ball printing methods exist—and which fit OEM orders?

Many techniques are advertised, but only three consistently meet OEM needs on curved golf balls: Pad Printing, UV-DTF Transfer, and UV Direct Printing. Screen and Offset help create films, and industrial coding handles batch marks—not customer logos for OEM golf ball logo printing methods.

Methods suitable for OEM logos

Pad Printing leads large-scale OEM for cost, consistency, and durability. UV-DTF Transfer suits high-end or complex visuals with clear-coat. UV Direct Printing is best for small batches, fast proofs, and multi-design orders—still viable for small OEM lots.

These three are proven on spheres. They balance adhesion, abrasion resistance, and alignment on curved surfaces. Each supports Pantone control and production fixtures with different trade-offs on speed, cost, and artwork complexity.

Methods not suitable for OEM logos

Screen Printing and Offset/Litho are not used directly on balls; they’re flat processes or upstream for film making. Industrial coding applies batch numbers, not brand logos. Laser or heat transfer appears online, but reliability for spherical OEM is inconsistent.

OEM decisions must consider adhesion on 3D curves, repeatability, and post-print clear-coat compatibility. That is why the field converges on the three methods above.

✔ True — Mass production must match the approved sample precisely

Once a sample is approved, the spec (ink, film, clear-coat, cure) should be locked and carried forward to bulk production. Any substitution or deviation (fixtures, plate type, exposure time) must be pre-approved, or repeatability and durability will drift.

✘ False — “If the sample looks good, the mass goods will match automatically”

Bulk consistency never happens by accident. Without controlled jigs, plate settings, ink batches, and coating cure windows, you risk color shifts, mis-registration, and weaker adhesion even when the sample was perfect.

How does Pad Printing perform for OEM golf balls?

Pad Printing is the default for OEM golf ball logo printing methods when you want low cost, high throughput, and tough logos. A silicone pad transfers ink from a plate onto the curved ball, then the ball moves to clear-coat—delivering stable registration and abrasion resistance at scale.

What is Pad Printing?

Pad Printing transfers a 2D image via a compliant silicone pad to a 3D surface, excelling on spheres. It integrates with coating lines (print → clear-coat) and uses fixtures to lock alignment, making it ideal for ≥1,000-unit OEM orders with strict color and position control.

This classic method masters curved geometry. With calibrated pad hardness, inking, and dwell, it deposits a uniform film on dimples. Integration with clear-coat improves scratch resistance and gloss. Expect consistent branding across large practice or retail runs.

Pros and cons

Pros: lowest cost, 800–1,500 balls/hour, strong wear resistance, stable registration. Cons: gradients/photos are hard, multi-color needs tight registration, and fixtures are mandatory.

For logos with 1–2 Pantone colors and clean edges, Pad Printing sets the benchmark. Complex tonal art is better suited to UV-DTF. Multi-color pad stacks work but add setup and alignment time. Good fixturing and plate quality are non-negotiable.

📊 Pad Printing – Cost & Time Estimates (Single Color, One Side, ≥1,000 Balls)

| Region | Plate/Setup (USD) | Print Cost (USD/ball/side) | Notes |

|---|---|---|---|

| China | $20–45 / color | $0.04–0.08 | Integrated with coating; high throughput |

| Taiwan | $16–50 | $0.07–0.15 | Higher labor & fixture cost |

| Japan | $0–25 | $1.10–1.60 | Public B2C pricing baseline |

| USA | ~$40 + PMS $20 | $0.55–0.70 (+$0.25 for 2nd side) | Service providers |

| Vietnam | $4–8 | $0.05–0.10 | Low labor & plate fees |

📌 Note: These prices are based on bulk service quotes. OEM lines with integrated coating may offer lower unit costs.

📌 Time Estimate (5,000 balls): ~3.5–7 hours (800–1,500 balls/hour).

Quality checklist

Check registration, color delta, dead spots, and even ink film. Run abrasion (100 brush strokes) and tape-pull adhesion on printed areas. Verify fixtures keep XY/rotational alignment within spec across shifts.

A quick incoming QC sheet can catch 90% of issues: plate wear, pad damage, viscosity drift, or cure variance. Lock PMS with drawdowns on the actual ball substrate.

When is UV-DTF Transfer the best choice for OEM golf balls?

Use UV-DTF Transfer when the artwork is complex, gradient-heavy, or photo-like and you want premium finish. You print on film first, transfer it to the ball, then clear-coat—achieving rich detail and strong durability for high-end OEM golf ball logo printing methods.

What is UV-DTF Transfer?

The logo is printed onto a UV-cured film, positioned on the ball, transferred with pressure, then locked under clear-coat. The process yields crisp edges, smooth gradients, and depth that standard Pad Printing cannot deliver on curved surfaces.

Think of it as a controlled “decal” for spheres. Because you print flat first, registration and detail are excellent. When combined with coating, the logo stands up to handling and bag wear while keeping a premium look.

Pros and cons

Pros: superb visual fidelity, gradients/photos supported, strong durability with clear-coat. Cons: more steps (print film → apply → clear-coat), slower takt, and higher cost per ball.

UV-DTF is the right tool for limited editions, co-brands, and gift boxes. It trades cycle time for brand wow. Plan for careful film handling, edge control, and post-coat cure to avoid lift or silvering at the perimeter.

📊 UV-DTF Transfer – Cost & Time Estimates

| Region | Material Cost (USD/ball) | Transfer Labor (USD/ball) | Total Cost (USD/ball) | Notes |

|---|---|---|---|---|

| China | $0.02–0.04 | $0.10–0.20 | $0.12–0.24 | Based on ~0.8" logo size |

| Taiwan | $0.02–0.05 | $0.12–0.25 | $0.14–0.30 | Mature material tech |

| Japan | $0.03–0.07 | $0.20–0.40 | $0.23–0.47 | Gift/keepsake pricing |

| USA | $0.03–0.08 | $0.25–0.60 | $0.28–0.68 | Area-based service pricing |

| Vietnam | $0.01–0.03 | $0.10–0.18 | $0.11–0.21 | Low labor; scaling capacity |

📌 Time Estimate (5,000 balls): ~100–120 hours including transfer and clear-coat.

✅ Quality Checklist – UV-DTF Transfer

-

Check for bubbles or wrinkles in film application.

-

Ensure edge integrity: no lifting or curling after transfer.

-

Re-test abrasion resistance post clear-coat (e.g., brush or tape test).

-

Confirm Pantone color accuracy on actual curved substrates.

-

Run impact simulation (e.g., steel ball drop or bag tumbling test).

-

Re-inspect after 24-hour cure to detect delayed failures.

Is UV Direct Printing right for OEM golf balls?

Choose UV Direct Printing to eliminate plates, move fast on proofs, and handle many designs. It prints straight on the ball, delivering vivid color and agile changeovers—but abrasion resistance usually trails clear-coat systems in OEM golf ball logo printing methods.

What is UV Direct Printing?

UV Direct jets ink directly onto the ball and cures it instantly. It excels at fast sampling, frequent art swaps, and small multi-design batches where setup time must be near zero and on-press tweaks are common.

Like DTG for shirts, this approach shines when flexibility is king. Head height, dwell, and adhesion promoters matter. With the right compatible surfaces or primers, adhesion improves, but still validate for your duty cycle.

Best for short runs and flexibility

For pilots, e-commerce bundles, and club-member personalization, UV Direct gives unmatched agility. You avoid plate fees, change designs in minutes, and reproduce color-rich marks with minimal downtime.

This is how brands explore variations and react to small campaigns. It also pairs well with marketplaces where SKUs rotate fast. Expect higher per-ball cost than Pad Printing but savings in NRE and time.

How to Prepare Artwork for UV Direct Printing

UV Direct lets you swap designs fast—ideal for small-batch OEM with high SKU variety.

No plates are needed. Just upload your file, and the RIP software takes care of layering, white base control, and spot-color mapping.

To streamline OEM jobs:

-

Use vector files (AI, EPS, PDF); high-res PNG also works

-

Convert all text to outlines; embed Pantone codes if needed

-

Allow ±0.5 mm tolerance for ball curvature

-

Confirm if a surface primer is needed for your ball model

-

Include trim boxes and bleed margins in print zone

💡 Most UV vendors offer mockup services. Share your artwork early to speed up sampling.

📊 UV Direct Printing – Cost & Time Estimates

| Region | Setup Cost (USD) | Print Cost (USD/ball/side) | Notes |

|---|---|---|---|

| China | ≈ $0 | $0.12–0.30 | OEM scale may lower cost |

| Taiwan | $10–30 | $0.15–0.40 | Equipment + labor higher |

| Japan | $20–50 | $0.20–0.60 | Focus on custom small batch |

| USA | $30–60 | $0.25–0.70 | Gift/print providers |

| Vietnam | $5–20 | $0.10–0.25 | Competitive labor; growing capacity |

📌 Time Estimate (5,000 balls): ~90–100 hours (throughput ~60 balls/hour).

Quality checklist

Run immediate rub tests (alcohol wipe ×500), check adhesion after full cure, and coin-scratch for surface hardness. Verify color consistency across SKUs and ensure primers, if used, match ball cover chemistry.

Because adhesion is the limiter, keep a controlled checklist. Tune lamp intensity and dwell for full cure, and record settings per SKU for repeatability.

How do Pad, UV-DTF, and UV Direct compare side by side?

At a glance: Pad Printing = lowest cost and fastest; UV-DTF = highest visual fidelity with clear-coat; UV Direct = fastest sampling and most flexible. The right method depends on your art, quantity, and durability target—use the quick facts, chooser, and time table below to decide.

Cost & speed at a glance (quick facts)

-

Pad Printing — lowest unit cost; ~800–1,500 balls/hour; best for ≥10k simple one-side logos; integrates with coating lines for durable, repeatable results.

-

UV-DTF Transfer — premium visuals under clear-coat; ~100–120 hours / 5k including transfer + coating; higher unit cost but best for gradients/photos and co-brands.

-

UV Direct — agile sampling and multi-SKU flexibility; ~90–100 hours / 5k (~60 balls/hour); no plate fees; ideal for <1k orders or frequent artwork swaps.

Use-case mapping (quick chooser)

Match method to scenario: large retail and range balls favor Pad, premium gifts and co-brands point to UV-DTF, and SKU-rich e-commerce and pilots lean UV Direct.

| Scenario | Recommended Method | Why |

|---|---|---|

| Practice balls; mass retail | Pad Printing | Lowest cost; high abrasion resistance |

| Tournament/brand collabs | UV-DTF + clear-coat | Complex art; premium look |

| E-commerce, many SKUs | UV Direct | No plates; fast swaps |

| Certified play balls | Pad + coating line | Integrated, repeatable quality |

Time estimate for 5,000 balls (single-color, one side)

Use this to scope line booking. Pad Printing finishes in 3–6 hours post-plate; UV Direct needs ~83 printing hours; UV-DTF takes ~100–120 hours due to transfer and coating steps.

| Process | Plate/Film Time | Print Time (5,000) | Total Est. | Notes |

|---|---|---|---|---|

| Pad Printing (1c/1s) | Photo plate ~30 min; laser 5–10 min | 800–1,500 balls/hr → 3–6 hr | ~3.5–7 hr | 2-color adds registration time |

| UV-DTF Transfer | Film ~30 min; transfer ~1 min/ball; clear-coat ~5 min/ball (parallel) | ~83 hr transfer | ~100–120 hr | Many steps; premium visuals |

| UV Direct | No plate; setup 5–10 min | ~60 balls/hr → ~83 hr | ~90–100 hr | High resolution; variable-friendly |

FAQ: OEM Golf Ball Logo Printing

These short answers help you move from research to action. They address the most common doubts on durability, coatings, color control, and small-batch feasibility for OEM golf ball logo printing methods.

Can I print gradients or photo-like logos on balls?

Yes—use UV-DTF Transfer with clear-coat for smooth gradients and photos. Pad Printing handles solid Pantones best; UV Direct prints complex art but may trail coating systems in scratch resistance.

Gradients stress curved registration and dot gain. UV-DTF sidesteps this by printing flat onto film and transferring to the ball, then sealing. Test a sample under abrasion to confirm the finish meets your use case.

Do I need clear-coat over the logo?

For Pad Printing in OEM lines, a post-print clear-coat is standard and boosts durability. For UV-DTF it is essential to lock edges and add wear resistance. UV Direct may run coat-free, but consider a compatible primer or topcoat for heavy use.

Clear-coat also unifies gloss and feel. If your balls already have a finish, confirm inter-coat adhesion between logo and top varnish.

How do I control Pantone colors across batches?

Lock the ink system, plate exposure, pad hardness, and viscosity window; keep drawdowns on the actual ball cover. For UV-DTF and UV Direct, color-manage output with device profiles and verify on curved samples, not flats.

Batch control beats guesswork. Save settings per SKU and confirm ΔE within tolerance after cure.

Can UV Direct be used for OEM bulk orders?

Yes for small batches or high-mix orders; not ideal for very large, single-art runs where Pad Printing dominates on cost and speed.

UV Direct shines in SKU diversity. As quantities grow and art stabilizes, Pad Printing’s economics and durability win.

✔ True — Unit price must be weighed with risk and service

A lower quote may hide weaker QC, longer lead time buffers, or less control of inks and fixtures. Evaluate total landed cost, schedule risk, and after-sales support—not just unit price—to secure reliable OEM deliveries.

✘ False — “Cheaper per unit always means a better deal”

Ignoring QC and service often creates rework, returns, and delays that dwarf savings. Balanced decisions consider durability targets, sampling speed, and supplier accountability alongside price.

What to Look for in a Reliable OEM Printing Supplier

Choose a supplier who matches your method with proven workflow.

For Pad Printing, confirm in-line coating integration. For UV-DTF, ask about curing consistency. For UV Direct, test adhesion on your actual ball cover.

Here’s what to ask:

-

Can they handle full in-line coating + printing?

-

Do they offer Pantone color matching and visual sample proofing?

-

Can they ensure mass production matches the approved sample?

-

Will they run abrasion / adhesion / weathering tests per method?

👉 If not, quality and consistency will vary—even with the right printing method.

Key takeaway: Choose Pad Printing for long, consistent OEM runs; select UV-DTF + clear-coat for premium, complex visuals; use UV Direct for fast proofs and small, multi-design batches. This is the practical core of OEM golf ball logo printing methods.

You might also like — How to Source OEM Golf Balls from China: Specs, MOQ & Lead Time