China vs America Golf Ball Costs: Labor, Materials, Packaging

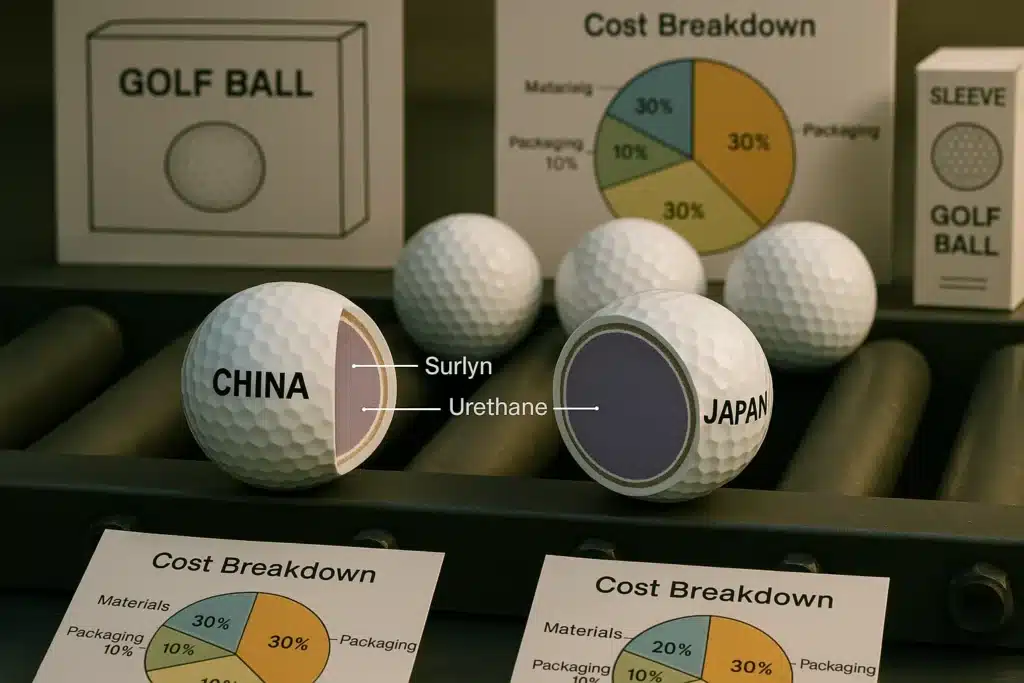

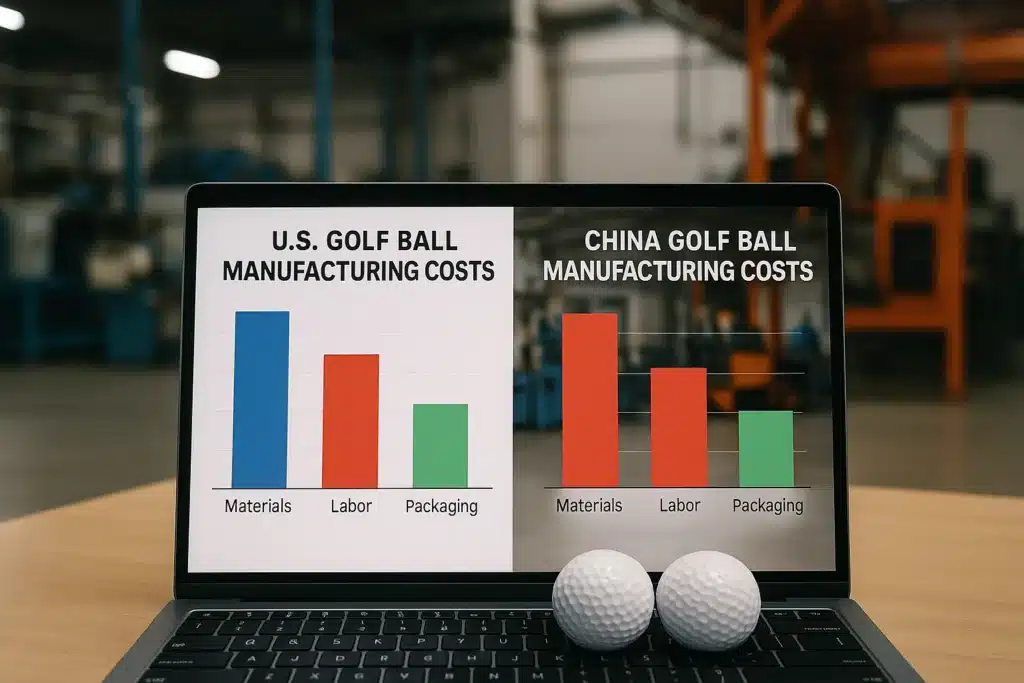

If you need a cost-true, compliance-aware plan for where to make which golf balls, here’s the headline: both the U.S. and China can produce 2–5 layer Surlyn/Urethane balls; the U.S. concentrates on brand-owned Tour-grade urethane, while China spans low-end to mid/high-end OEM with flexible MOQs and faster scaling. Always model